Efficient dust collecting bucket elevator

A bucket elevator, high-efficiency technology, applied in the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problems of air pollution, operation equipment and personnel hazards, sand escape, etc., to avoid dust pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

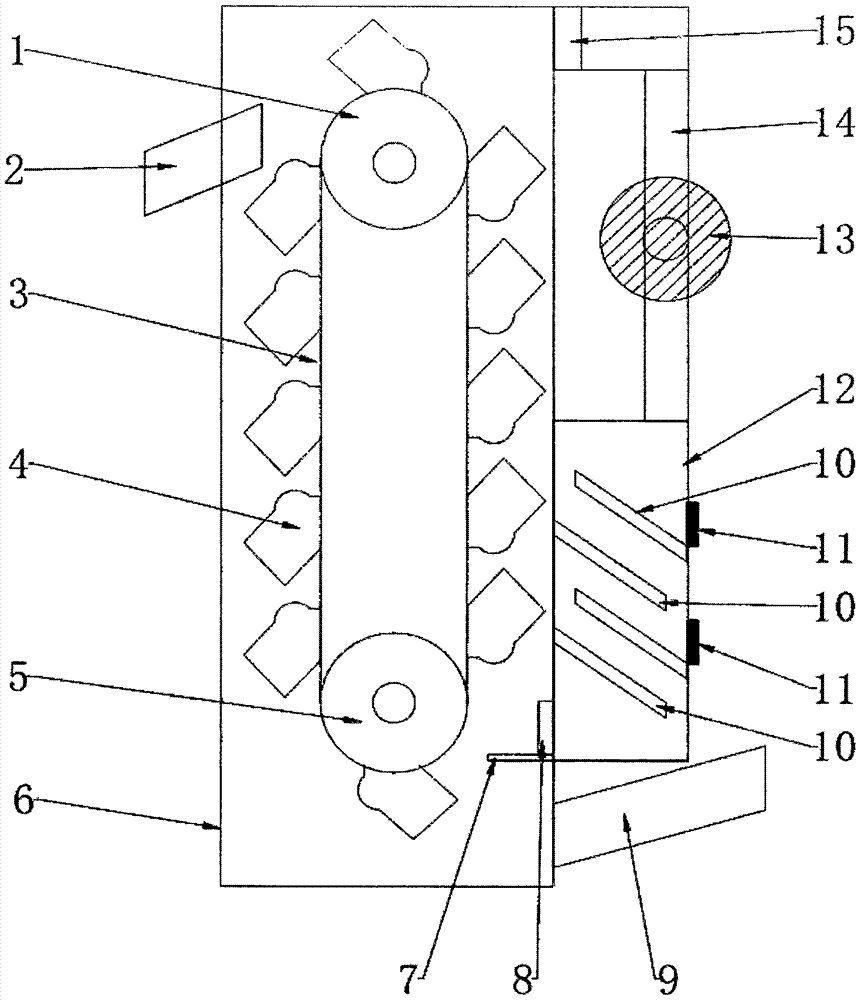

[0016] Such as figure 1 Shown: an efficient dust-removing bucket elevator, including a chassis 6, the upper and lower parts of the chassis 6 are respectively provided with a driven wheel 1 and a driving wheel 5, the driven wheel 1 and the driving wheel 5 are sleeved with a transmission belt 3, Twelve bucket lifts 4 are evenly distributed on the outside of the transmission belt 3, a feed hopper 9 is provided on the right side of the chassis 6 under the driving wheel 5, and a baffle 7 is provided on the inside of the chassis 6 on the upper side of the feed hopper 9 An air outlet 8 is provided on the inner wall of the case 6 on the side; the right side of the case 6 is provided with a settlement chamber 12, and the air outlet 8 is connected to the lower part of the settlement chamber 12; the upper end of the settlement chamber 12 is provided with a vertical air supply pipe 14, and the case 6 An air inlet 15 is provided on the right side of the upper end, and the air inlet 15 is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com