Automatic metering and feeding device of lightweight aggregate concrete and preparation method

A technology of lightweight aggregate concrete and feeding device, which is applied in clay preparation device, mixing operation control device, mixing operation control and other directions, can solve the problems of increasing production cost of lightweight aggregate concrete, reducing equipment utilization rate, affecting settlement and settlement, etc. , to achieve the effect of improving production efficiency and equipment utilization, reducing production costs and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

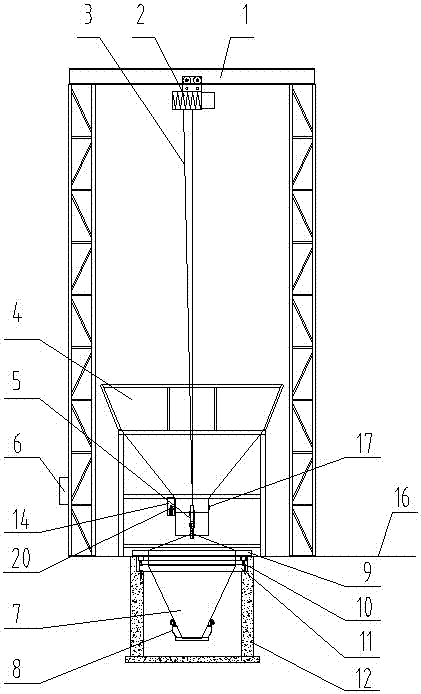

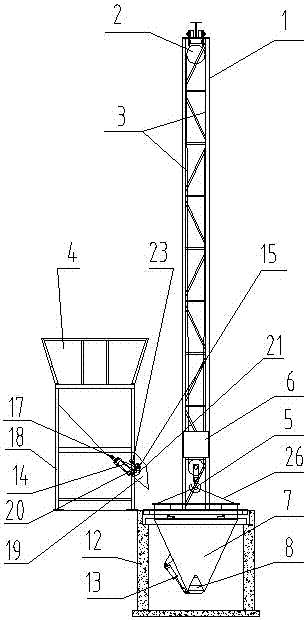

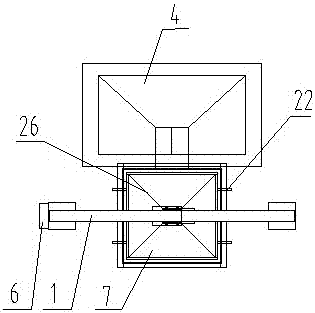

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the present embodiment includes a collection bin 4 fixed on a support frame 18, a door frame 1 fixed on the foundation, an electric hoist 2, a weighing bucket 7, a plurality of pressure sensors 10, a weighing bucket foundation pit 12, a measuring bucket Frame 9, measuring lower frame 11, discharge door A 15, discharge door B 8, closing and opening mechanism of discharge door A, closing and opening mechanism of discharge door B and controller 6.

[0027]The upper end of the collection bin 4 is a feed port, the rear end has a discharge port below, and the bottom surface is inclined downward to the discharge port. A discharge door A 15 is hingedly fixed on the discharge opening, and a discharge drainage groove 19 inclined downward is fixed at its l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com