Method for monitoring yarn at a workstation of a textile machine and textile machine for carrying out the method

A technology of workstations and textile machines, applied in textiles and papermaking, thin material handling, transportation and packaging, etc., can solve problems such as limited ability to respond flexibly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

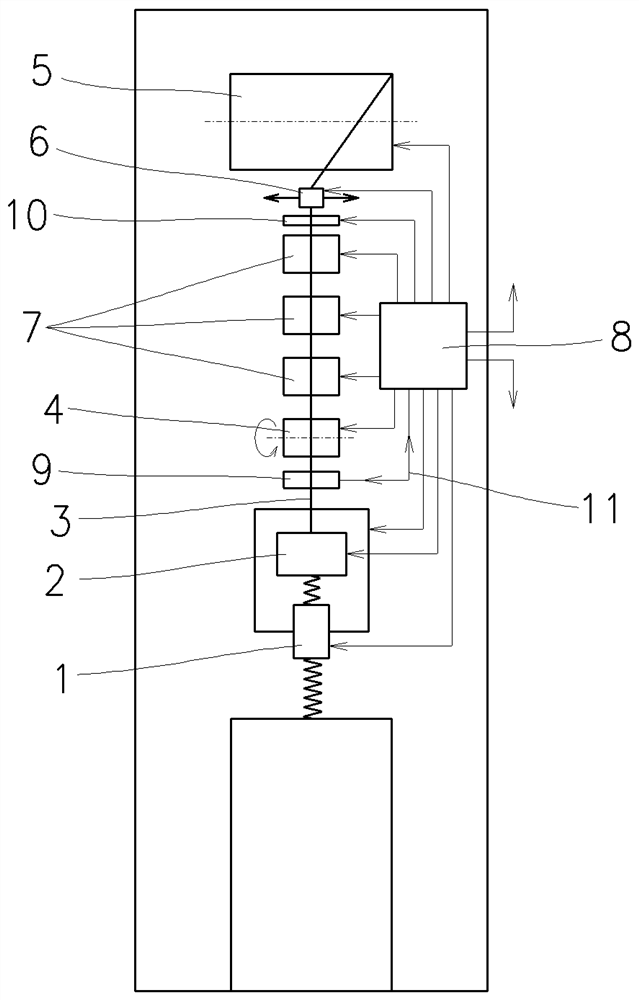

[0017] The invention will be described with reference to an exemplary embodiment of a yarn-making textile machine. The machine comprises at least one row of identical workstations arranged next to each other. Each workstation includes a system of working nodes, working devices, and working mechanisms to convert fibers into yarns. In the direction of fiber movement, the workstation firstly comprises a fiber feed device 1 , the outlet of which leads to a spinning unit 2 of the fibers, in which a continuous thread 3 is formed from the fibers, for example by means of a spinning rotor or spinning nozzle. The yarn 3 is drawn from the spinning unit 2 by the yarn pulling mechanism 4 and wound on the bobbin 5 , whereby the yarn traverses the width of the bobbin 5 by the yarn traversing device 6 . If desired, according to the specific embodiment, further nodes 7 are arranged between the pulling mechanism 4 of the yarn from the spinning unit 2 and the traversing device 6 of the yarn on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com