Self-centered side collision preventing bearing

A kind of middle-proof and bearing technology, applied in the direction of bearing components, shafts and bearings, bearing unloading, etc., can solve the problems of deformation, detachment and increased resistance of rolling groove or ball 3, so as to reduce friction, avoid contact, improve The effect of impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

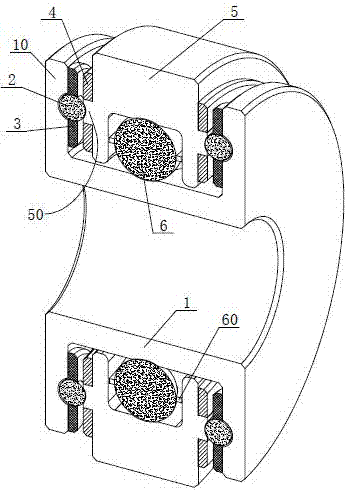

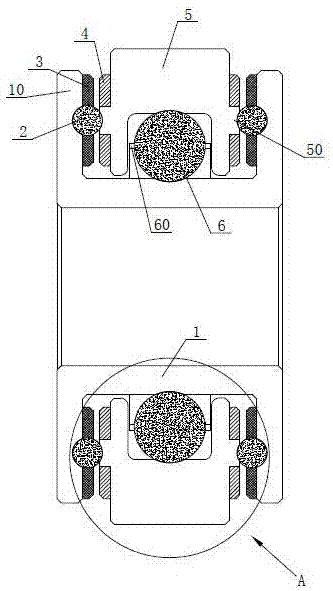

[0033] Such as Figure 5 The shown self-centering anti-side impact bearing includes inner ball 6, outer ring 5, inner magnetic ring 4, outer magnetic block 3, outer ball 2 and inner ring 1 from the inside to both sides (in order to better see the position relationship, the outer ring 5 and the inner ring 1 are all cut from the middle in the figure).

[0034] A cage 60 is provided on the outside of the inner ball 6 for maintaining the distance between the balls.

[0035] Such as Figure 4 As shown, an inner rolling groove is provided inside the outer ring 5 to cooperate with the inner ball 6 and press the inner ball 6 against the outer surface of the inner ring 1 .

[0036] Two sidewalls of the outer ring 5 are provided with protruding rings 50 protruding from the surface of the side walls of the outer ring 5 , and the protruding rings 50 are provided with inwardly recessed outer rolling grooves 51 . The outer ring 5 in this embodiment is made of stainless steel, and the pro...

Embodiment 2

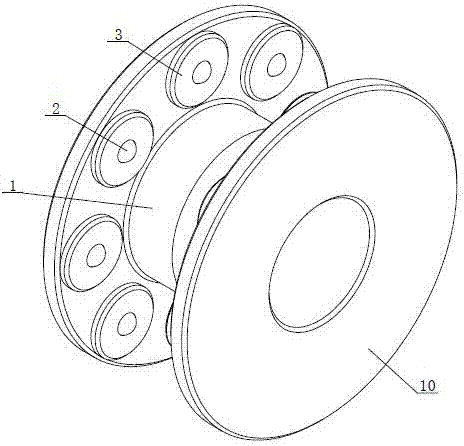

[0045]Such as Figure 6 As shown, this embodiment is based on Embodiment 1, and integrates all the outer magnetic blocks 3 into a whole. The outer magnetic block 3 in this embodiment is annular, and the outer magnetic block 3 surrounds the inner ring 1 and is connected to the inner ring Circle 1 is set concentrically.

[0046] The outer magnetic block 3 is a structure of a whole magnetic ring. There are multiple holes on the magnetic ring for the outer ball 2 to be exposed. The advantage is that it is easy to install and can provide greater magnetic repulsion. However, when assembling and disassembling, it needs Overall disassembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com