Membrane type air spring for cab with additional gas chamber

A technology of adding air chambers and air springs, applied in the direction of springs, springs/shock absorbers, gas shock absorbers, etc., can solve the disadvantages of air spring life, ride comfort, low bearing capacity of membrane air springs, and insufficient utilization Cover volume and other issues, to achieve the effect of increasing effective working volume, reducing unsprung mass, and improving ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

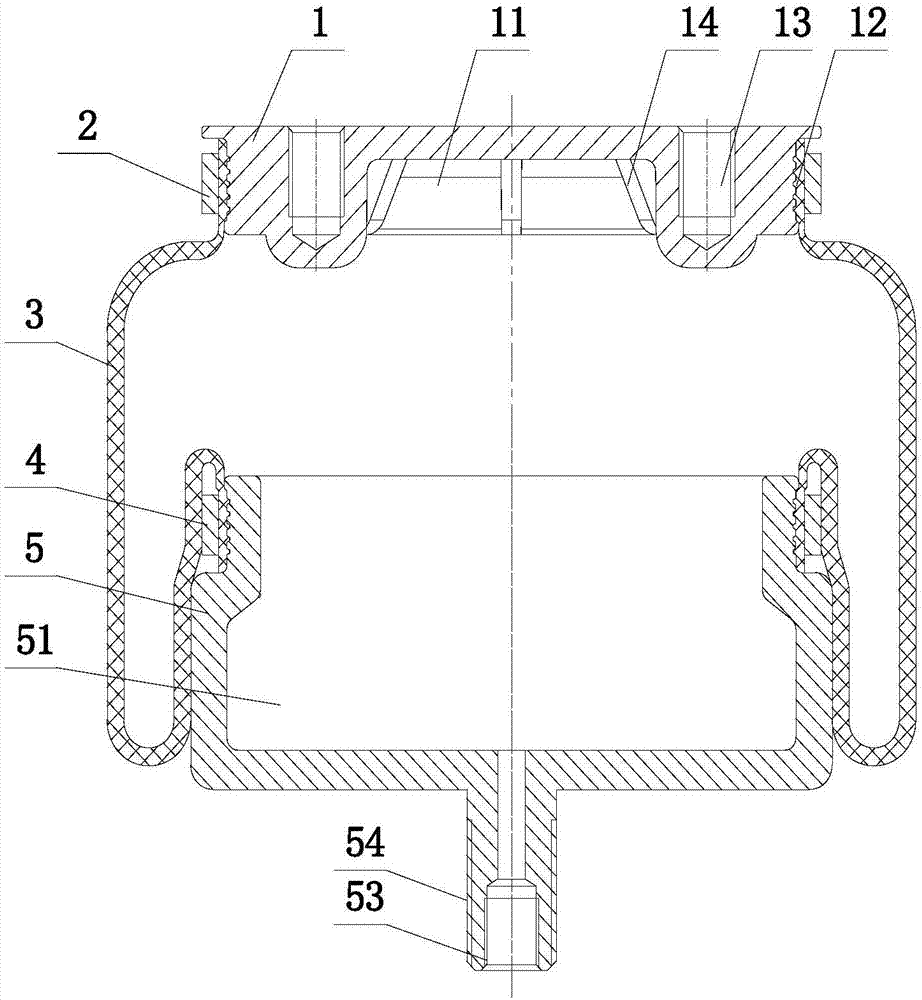

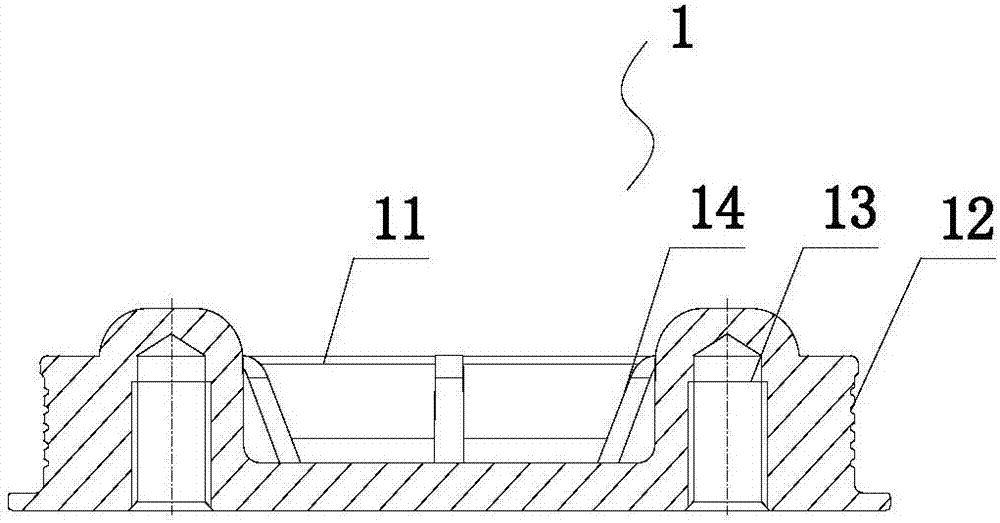

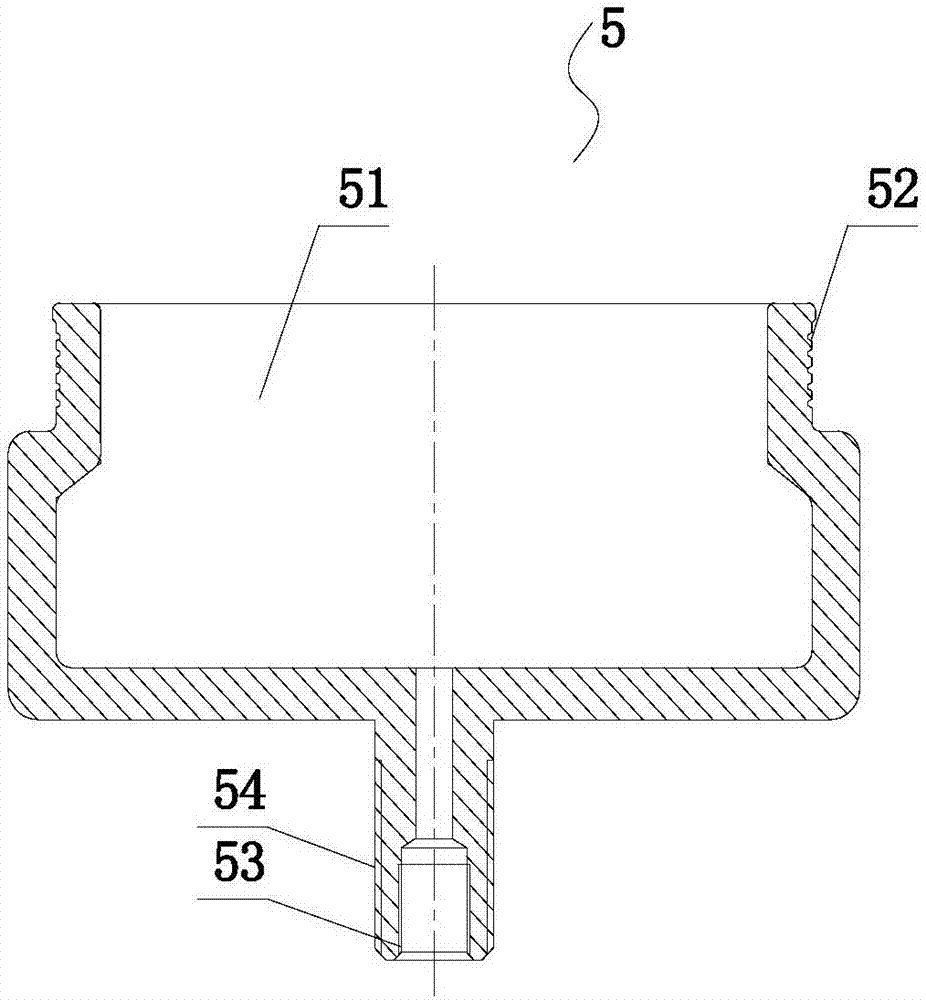

[0025] Such as figure 1 As shown, a diaphragm air spring with an additional air chamber according to the present invention includes an upper cover 1, a rubber air bag 3 and a lower piston 5 sequentially connected from top to bottom, and the periphery of the upper cover 1 is provided with an upper The cover 1 is an upper pressing device that seals tightly, and the periphery of the lower piston 5 is provided with a lower pressing device that seals the lower piston 5 tightly. The inside of the aluminum upper cover 1 is an inner hollow structure 11. The inner cavity of the lower piston 5 is also provided with a hollow structure 51 as an additional air chamber. Such as Figure 4 As shown, the rubber airbag 3 is a straight cylindrical structure.

[0026] Such as figure 2 As shown, the upper pressing device includes an upper pressing ring 2 and an anti-slip line 12 corresponding to the periphery of the upper cover 1 , and the upper cover 1 is provided with internal threaded holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com