Line contact place temperature measurement and warning device

A technology of temperature measuring device and alarm device, which is applied in the field of electric power, and can solve problems such as interrupting industrial and agricultural production and residential electricity consumption, affecting the normal operation of electrical equipment, and failing to detect in time during the inspection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

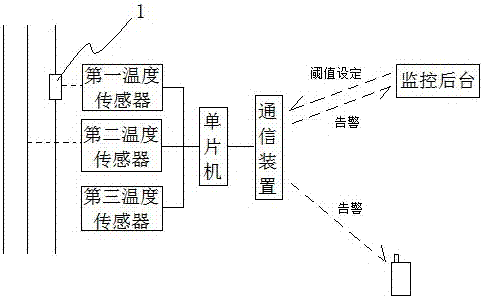

[0013] like figure 1 As shown in , this embodiment includes a temperature measuring device, a judging device connected to the temperature measuring device, and a communication device connected to the judging device; wherein, the temperature measuring device adopts a temperature sensor, and the temperature measuring device includes a temperature sensor set at the line contact point 1. The sensor senses the temperature at the junction and converts it into an electrical signal output, the temperature sensor installed on the adjacent phase line senses the temperature of the adjacent phase line and converts it into an electrical signal output, and the temperature sensor senses the ambient temperature; The judging device is a single-chip microcomputer, and the data of the single-chip microcomputer is connected to each temperature sensor to continuously obtain the temperature data at the joint, the temperature data of the adjacent phase line of the joint line, and the temperature data...

Embodiment 2

[0015] like figure 1 As shown in , this embodiment includes a temperature measuring device, a judging device connected to the temperature measuring device, and a communication device connected to the judging device; wherein, the temperature measuring device adopts a temperature sensor, and the temperature measuring device includes a temperature sensor set at the line contact point 1. The sensor senses the temperature at the junction and converts it into an electrical signal output, the temperature sensor installed on the adjacent phase line senses the temperature of the adjacent phase line and converts it into an electrical signal output, and the temperature sensor senses the ambient temperature; The judging device is a single-chip microcomputer, and the data of the single-chip microcomputer is connected to each temperature sensor to continuously obtain the temperature data at the joint, the temperature data of the adjacent phase line of the joint line, and the temperature data...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap