Automobile chassis automatic detection equipment and automobile intelligent detection system

A technology of automatic detection and automobile chassis, which is applied in the field of electronic communication, can solve the problems of time-consuming, labor-intensive, low inspection efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

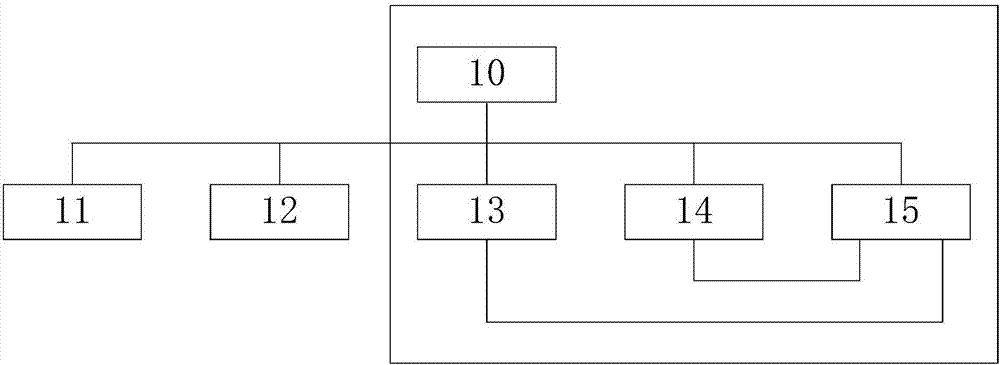

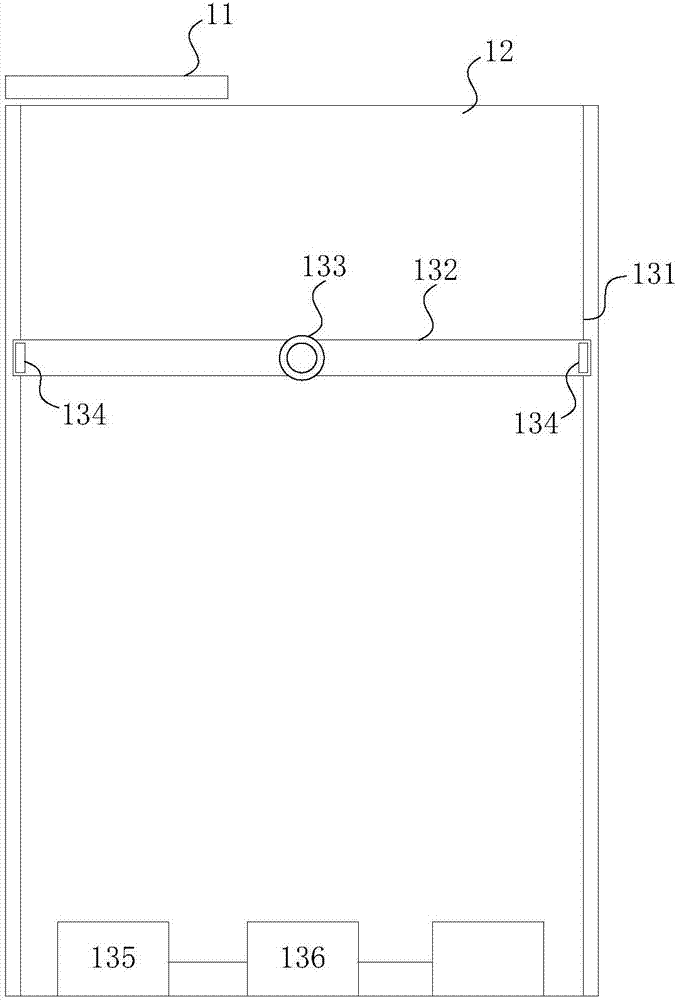

[0110] see figure 1 , the present invention discloses an automatic chassis detection device, which includes: a vehicle type acquisition module 11, a position adjustment mechanism 12, an image acquisition module 13, an image comparison module 14, an automatic key comparison area formation module 15, The main control module 10, the main control module 10 is respectively connected with the vehicle type acquisition module 11, the position adjustment mechanism 12, the image acquisition module 13, the image comparison module 14, the key comparison area automatic formation module 15, and the key comparison area automatic formation module 15 respectively The image acquisition module 13 and the image comparison module 14 are connected.

[0111] The vehicle type obtaining module 11 is used to identify the unique identification code of the vehicle, and obtain the information of the vehicle, including the vehicle model and the setting specifications corresponding to the corresponding mode...

Embodiment 2

[0130] A kind of automatic detection equipment of automobile chassis, described automatic detection equipment of chassis comprises:

[0131] - The model acquisition module is used to identify the unique identification code of the vehicle and obtain the information of the vehicle, including the vehicle model and the setting specifications corresponding to the corresponding model;

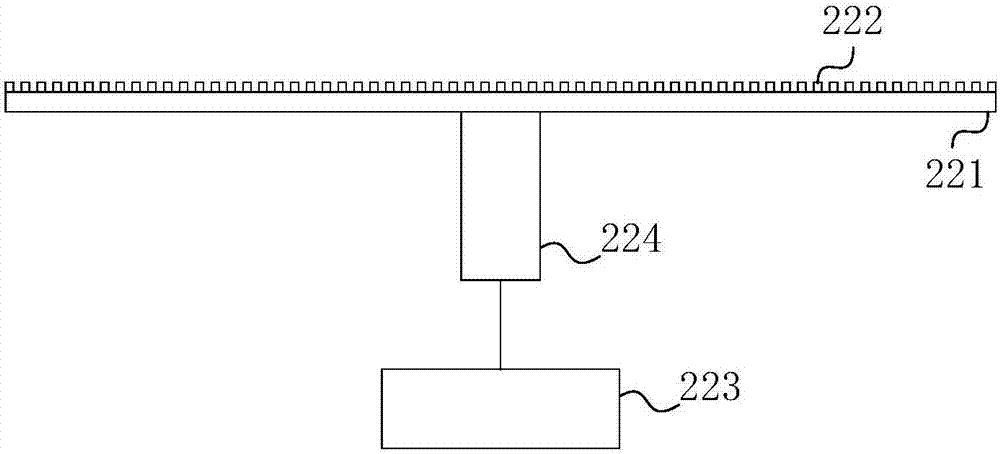

[0132] - a position adjustment mechanism for adjusting the vehicle to a preset position;

[0133] - an image acquisition module, used to acquire the image of the set area of the vehicle chassis;

[0134] - The image comparison module is used to compare the image acquired by the image acquisition module with the set image in the database to determine whether there is any abnormality in the vehicle chassis; the image comparison module focuses on the comparison of the set key areas: improve The similarity threshold of this area improves the resolution of image acquisition in this area, and the images...

Embodiment 3

[0137] see Figure 10 , The present invention discloses an intelligent detection system for automobiles, comprising automatic chassis detection equipment 1 , automatic tire deflation equipment 2 , and automatic detection equipment 3 for car body surface quality damage.

[0138] The automobile intelligent detection system includes: vehicle type acquisition module 11, position adjustment mechanism 12; chassis automatic detection equipment 1, tire automatic deflation equipment 2, vehicle body surface quality damage automatic detection equipment 3 all need to use vehicle type acquisition module 11, position adjustment Agency12. The chassis automatic detection equipment 1, tire automatic deflation equipment 2, and vehicle body surface quality damage automatic detection equipment 3 can use the same vehicle type acquisition module 11 and position adjustment mechanism 12, or different vehicle type acquisition modules 11 and position adjustment mechanisms 12.

[0139] The vehicle type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com