Industrial nitrogen dehumidification detection device

A detection device, nitrogen technology, applied in the direction of measuring device, dry gas arrangement, humidity control, etc., can solve the problems of nitrogen instability, detection, nitrogen leakage, etc., and achieve the effect of improving dehumidification efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

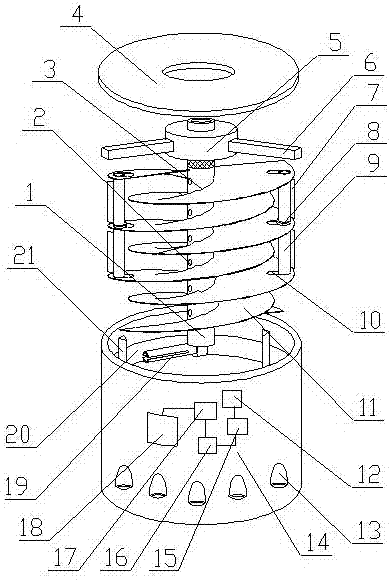

[0024]An industrial nitrogen dehumidification detection device of the present invention is realized in the following way: when in use, the hollow shaft part of the hollow shaft motor (5) is connected to the nitrogen cylinder, and the air distribution pipe (13) is respectively connected to the nitrogen pipe on the equipment, The power line on the arc-shaped copper plate (20) is connected to the power supply (12), the metal brush plate (7) is in contact with the corresponding arc-shaped copper plate (20), the circuit is connected and heated by the ceramic heating tube (9), and the main box heat exchange inside, and then inject the nitrogen in the nitrogen bottle, the nitrogen enters from the hollow shaft motor (5), then diffuses from the mesh basket to the surroundings, and diffuses along the helical blade (11), when the nitrogen goes along the helical blade ( 11) Diffusion operation is carried out, the main box is heated, the temperature changes, the internal moisture sinks, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com