Air-core coil winding equipment

A technology of hollow coils and winding equipment, which is applied in the manufacture of electrical components, inductors/transformers/magnets, circuits, etc., which can solve problems such as low production efficiency, high energy consumption, and burns, and achieve energy-saving design, reduce processing difficulty, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0114] Example one

[0115] Such as Figure 26 As shown, the hollow coil winding equipment includes a frame 1 on which a turntable 2 is provided, and the turntable 2 is connected with a turntable drive mechanism. The turntable drive mechanism includes any one of belt drive and gear drive. Turntable 2 rotates clockwise.

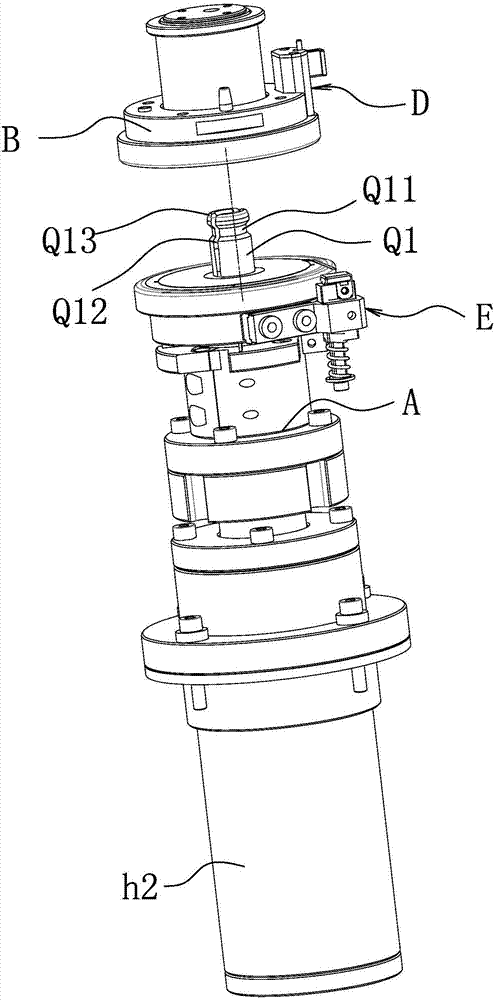

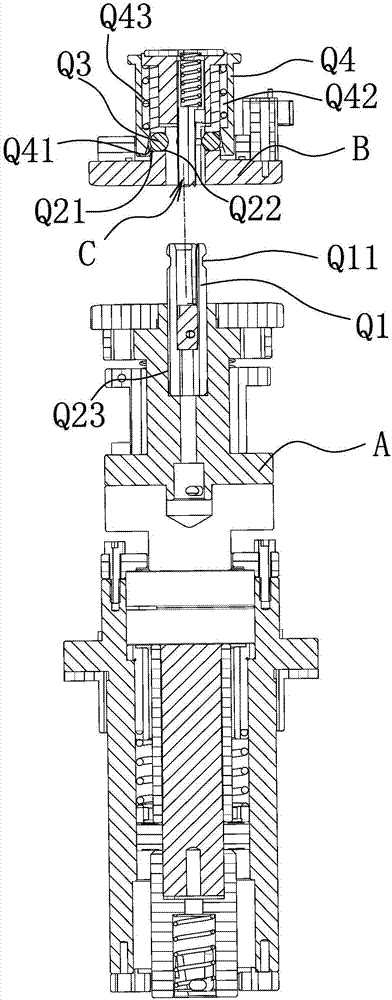

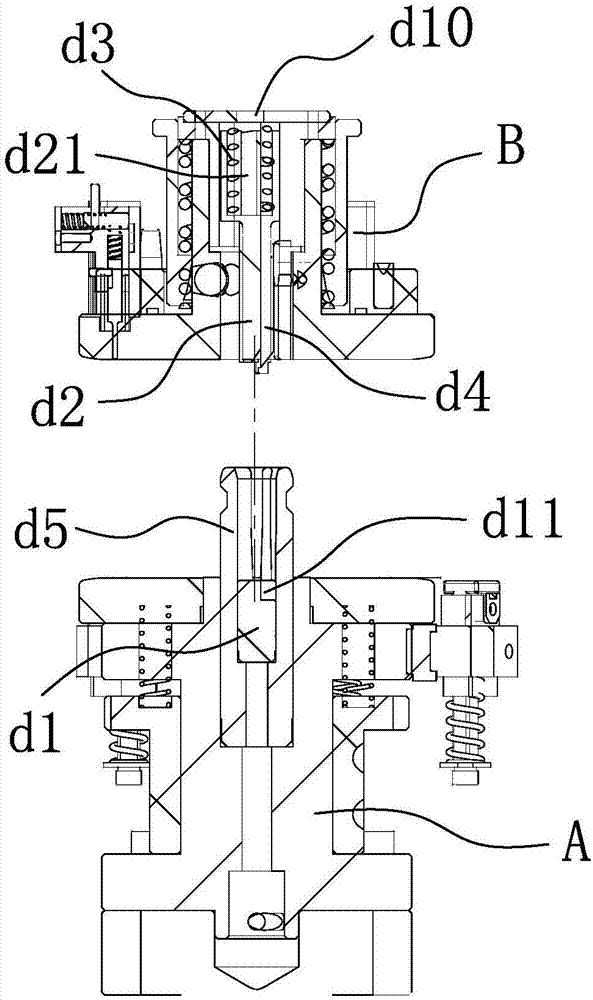

[0116] Such as Figure 1-2 , Picture 20 , Figure 26 with Figure 41-42 As shown, the frame 1 is provided with a wire passing mechanism 3 located on the periphery of the turntable 2 and capable of arranging a number of enameled wires horizontally and able to close the plurality of enameled wires side by side, and a plurality of lower jigs distributed in a circle are provided on the turntable 2 A. Each lower jig A is connected to the upper jig B through the jig clutch mechanism, and an inner wire that can clamp and pierce the hollow coil inner wire is set between the upper jig B and the lower jig A The head clamping and piercing mechanism C is provided on the out...

Example Embodiment

[0249] Example two

[0250] Such as Figure 26 As shown, the structure and principle of this embodiment are basically the same as those of the first embodiment, so I won’t repeat them here, and the difference lies in

[0251] The inner thread head clamping and piercing mechanism C provided on the frame includes any one of a ceramic heating rod j8 and a laser peeling device p2. That is, before entering the jig drive mechanism, the enameled wire is peeled off from the wire end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com