Substrate rotary apparatus and substrate alignment method

A technology of rotating device and substrate, applied in the field of PCB board manufacturing, can solve the problems of low printing efficiency and poor precision of PCB board, and achieve the effect of realizing automatic production, reducing production cost and reducing structural complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

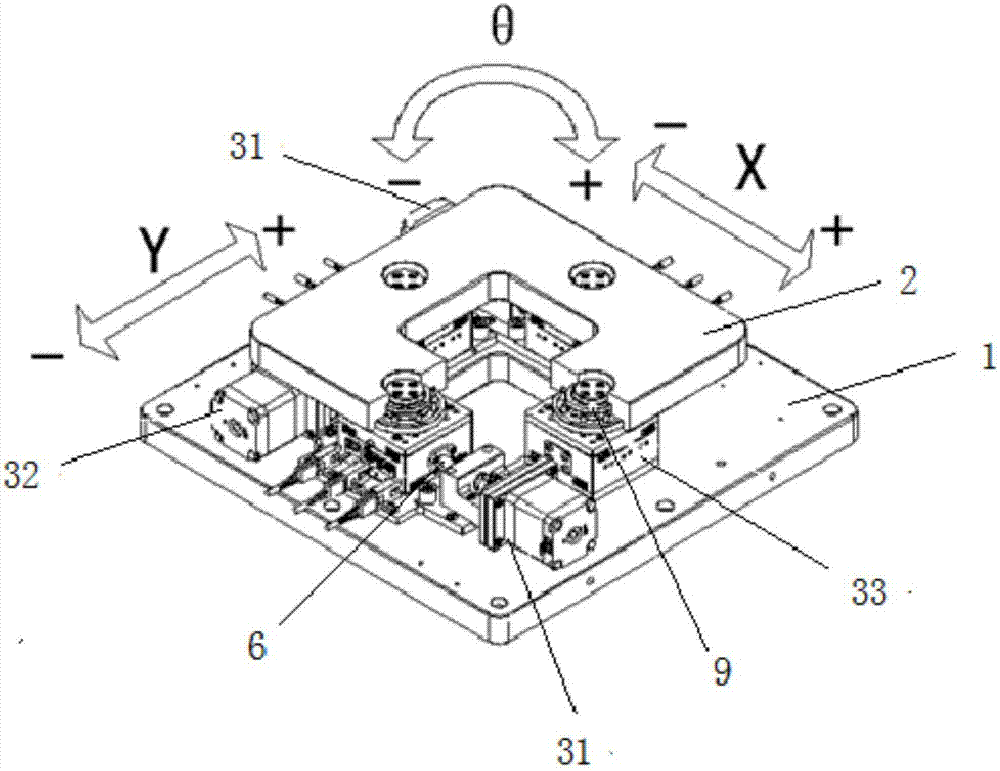

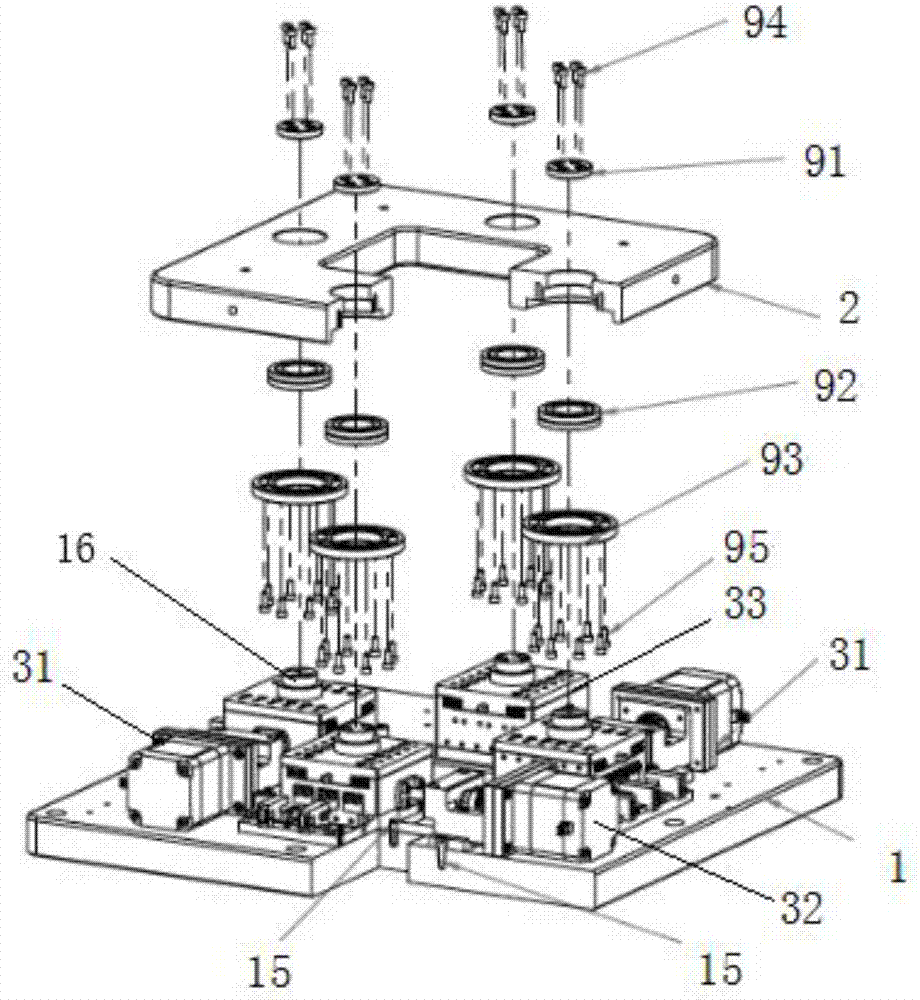

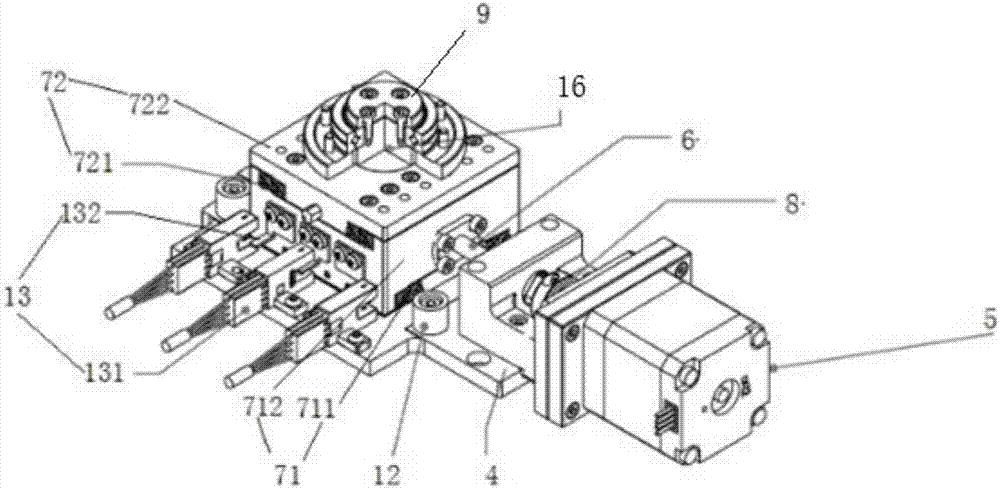

[0086] Such as Figure 1-2 As shown, the present invention discloses a substrate adjustment device, which includes a detection device, a data analysis device, a control device and a substrate rotation device, wherein the detection device is used to detect the initial position of the substrate, the data analysis device is connected to the detection device, and the data analysis The device analyzes the initial position information collected by the detection device and compares it with the predetermined position. The control device is connected to the data analysis device and the substrate rotation device respectively, and controls the substrate rotation device to perform corresponding operations according to the control instructions issued by the data analysis results. The ground adjustment action finally adjusts the substrate to the predetermined position.

[0087] The substrate rotation device of the present invention includes a base 1, a working platform 2, a driving device a...

Embodiment 2

[0099] This embodiment is a method for aligning a substrate by using the rotating device in Embodiment 1 to align the substrate, which mainly includes the following steps:

[0100] S1: Firstly, the initial position of the substrate is detected by the detection device; for example, the mark points on the substrate can be sequentially captured by the CCD camera, and then the initial position information of the substrate can be calculated and analyzed.

[0101] S2: Send the initial position information of the substrate detected by the CCD camera to the data analysis device, and the data analysis device compares and analyzes the initial position of the substrate with the predetermined position, and sends the analysis result to the control device, such as a PLC control device.

[0102] S3: The control device performs an alignment adjustment operation on the substrate according to the comparative analysis result of the data analysis device, and the substrate reaches a predetermined p...

Embodiment 3

[0116] Embodiment 3 is a kind of printing method of PCB board, and it comprises the steps:

[0117] S1: adopt the substrate alignment method as in embodiment 2 to perform automatic alignment operation on the PCB board;

[0118] S2: After the alignment is completed, input the PCB board into the printing device for printing operation.

[0119] Moreover, the printing operation of the previous PCB board and the alignment operation of the latter PCB board are carried out simultaneously, thereby improving the efficiency of PCB production and increasing the production capacity of the production line.

[0120] The substrate rotation device provided by the present invention satisfies the adjustment requirements of linear movement, rotation and rotational offset required in the substrate alignment adjustment process by being provided with linear actuation modules that can move independently or in combination in two linear directions. The θ-axis rotating motor that needs to be additiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com