Microwave dielectric ceramic material with low dielectric constant and preparation method thereof

A technology of microwave dielectric ceramics and low dielectric constant, applied in the field of electronic information materials, can solve the problems of high dielectric constant and high sintering temperature, and achieve the effect of low cost of raw materials and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

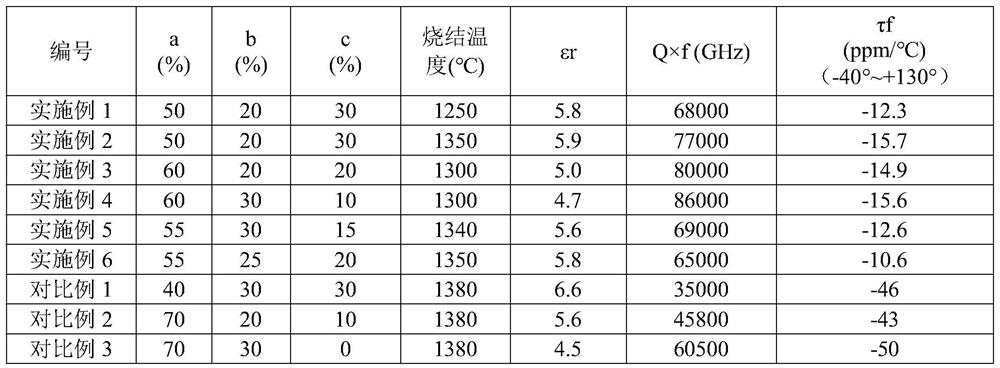

Examples

preparation example Construction

[0026] The present application also provides a method for preparing a microwave dielectric ceramic material with a low dielectric constant, which is used to prepare the above-mentioned microwave dielectric ceramic material with a low dielectric constant. It is characterized in that it includes the following steps:

[0027] S1: Weigh the aMgSiO by molar ratio 3 -bcordierite-cCaSiO 3 Each starting material in the indicated composition is prepared into a slurry;

[0028] S2: Calcining the slurry after drying to synthesize matrix powder;

[0029] S3: The matrix powder uses deionized water as the dispersion medium, and the mixed powder formed by the matrix powder and deionized water is dispersed, pulverized and dried by a pulverization process;

[0030] S4: Add PVA aqueous solution to the mixed powder, mix and then granulate, and press to form a cylindrical green body;

[0031] S5: Firing the microwave dielectric ceramics at an environment of 1250-1350°C for 2-10 hours.

Embodiment 1

[0034] Weigh out 50% MgSiO 3 , 20% cordierite and 30% CaSiO 3 Mix with deionized water as the dispersion medium, and use the crushing process to disperse and pulverize the ingredients to make a slurry; after drying the slurry, calcinate it at 1100°C for 2 hours to synthesize the matrix powder.

[0035] The matrix powder uses deionized water as the dispersion medium, and the mixed powder of the matrix powder and deionized water is dispersed, pulverized and dried by the pulverization process; then, PVA aqueous solution is added to the mixed powder and mixed for granulation. Press the cylindrical green body under the pressure of 4MPa; finally, in the atmosphere, heat the microwave dielectric ceramics at 1250°C for 2 hours.

Embodiment 2

[0037] Weigh out 50% MgSiO 3 , 20% cordierite and 30% CaSiO 3 Mix with deionized water as the dispersion medium, and disperse and pulverize the sub-materials by pulverization process to make slurry; after drying the slurry, it is calcined at 1150°C for 5 hours to synthesize matrix powder.

[0038] The matrix powder uses deionized water as the dispersion medium, and the mixed powder of the matrix powder and deionized water is dispersed, pulverized and dried by the pulverization process; then, PVA aqueous solution is added to the mixed powder and mixed for granulation. Under the pressure of 4MPa, it is pressed into a cylindrical green body; finally, in the atmosphere, it is kept at 1350°C for 5 hours and fired into microwave dielectric ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com