Manufacturing method of communication base station waveguide filter

A technology of a waveguide filter and a manufacturing method, which is applied to waveguide-type devices, resonators, electrical components, etc., to achieve the effects of steep frequency characteristics, good temperature characteristics, and high Q value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

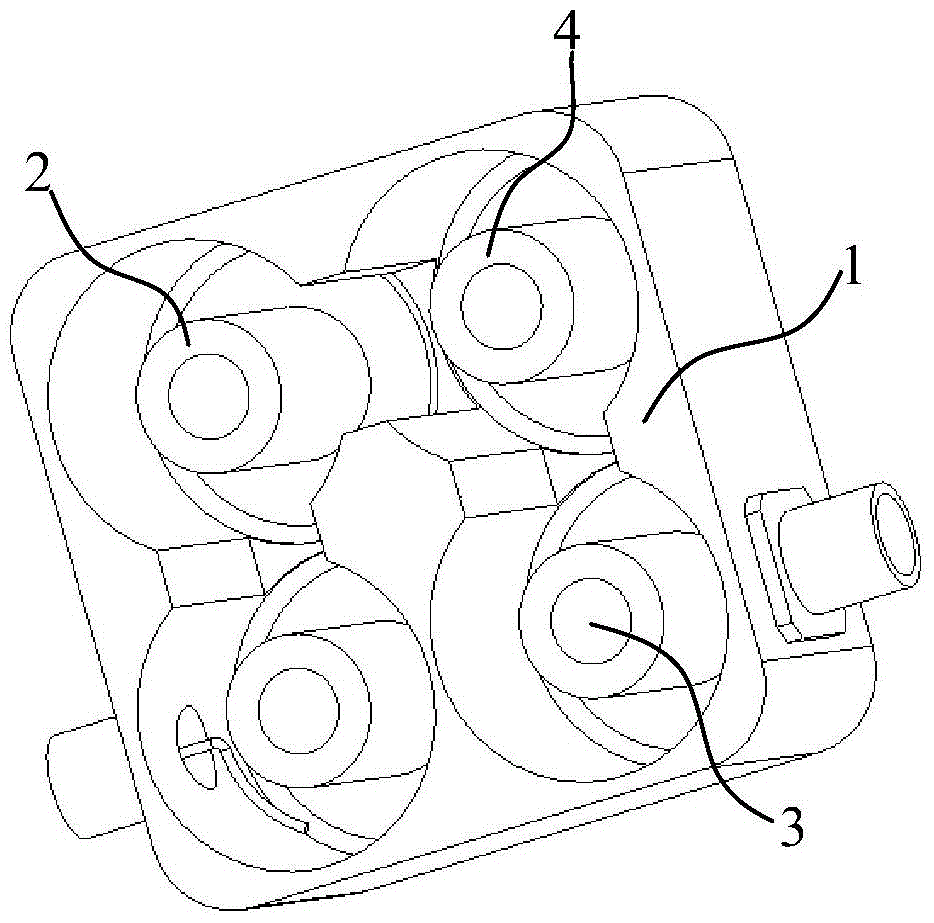

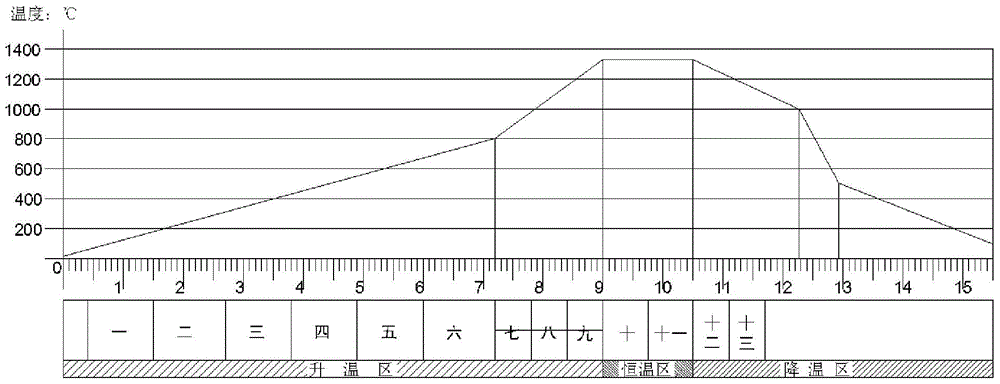

[0030] Embodiment 1~3: a kind of manufacturing method of communication base station waveguide filter, comprises cavity 1 and dielectric resonator 2, and described dielectric resonator is cylinder 4 with through hole 3; Described dielectric resonator 2 is made of following The component composition of mass percentage content is as shown in table 1:

[0031] Table 1

[0032]

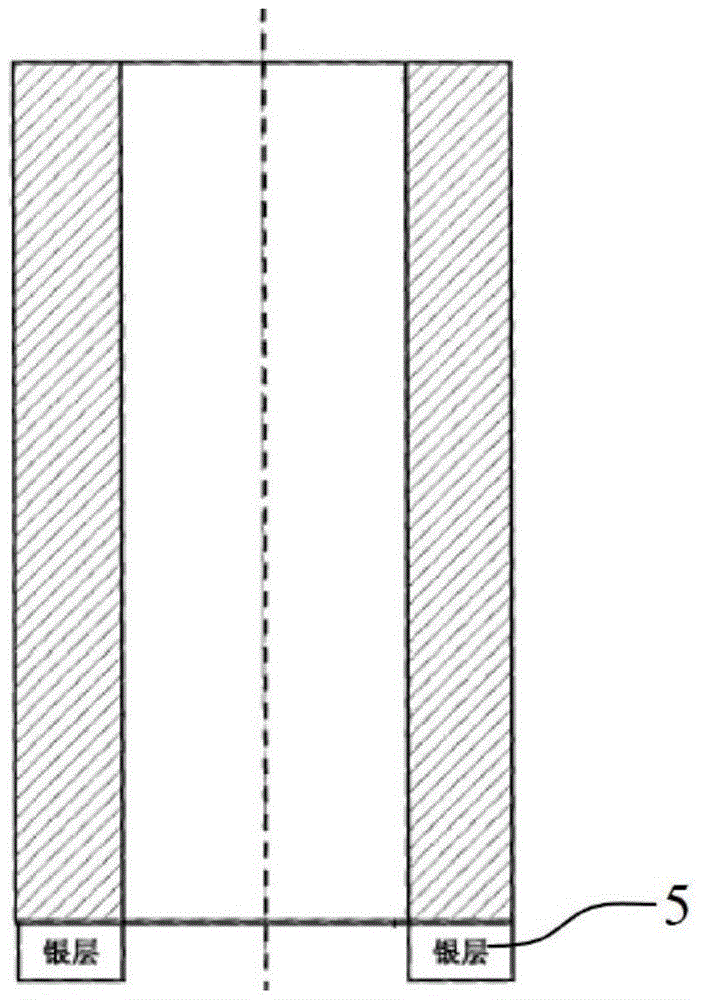

[0033] One end of the dielectric resonator 2 is plated with a silver layer 5, and the other end of the dielectric resonator 2 is welded in the cavity 1;

[0034] The cavity 1 is composed of the following components in mass percentage as shown in Table 2:

[0035] Table 2

[0036]

[0037] The relative permittivity of the cavity 1 is 9.5.

[0038] The above-mentioned dielectric resonator 2 is composed of the following components in mass percentage:

[0039] 30.5% calcium carbonate with a purity of 97.5%,

[0040] Alumina 10% with a purity of 97.5%,

[0041] 23% neodymium oxide with a purity of 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency temperature coefficient | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com