Manufacturing Process for Tunable Cavity Filters

A manufacturing process and filter technology, applied in the field of reciprocal microwave devices, to achieve the effects of steep frequency characteristics, good temperature characteristics, and high Q value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

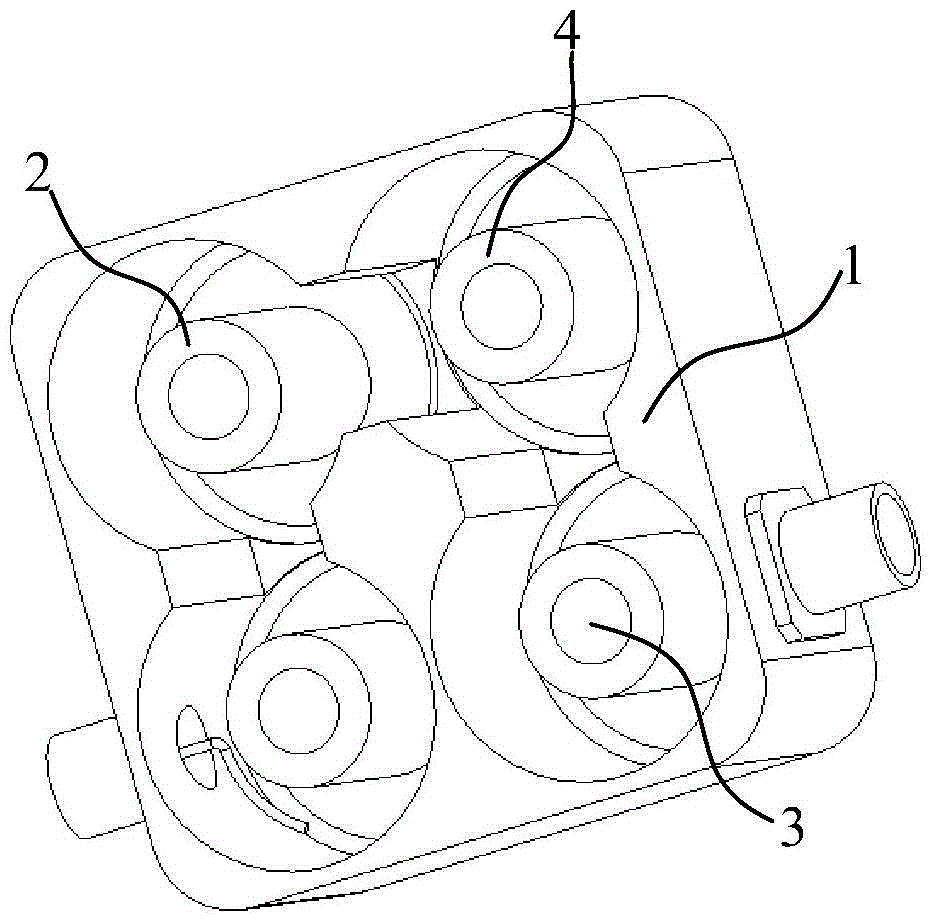

[0034] Embodiments 1 to 3: A manufacturing process for a tunable cavity filter, including a cavity 1 and a dielectric resonator 2, the dielectric resonator being a cylinder 4 with a through hole 3; the dielectric resonator 2 The composition of the following components by mass percentage is shown in Table 1:

[0035] Table 1

[0036]

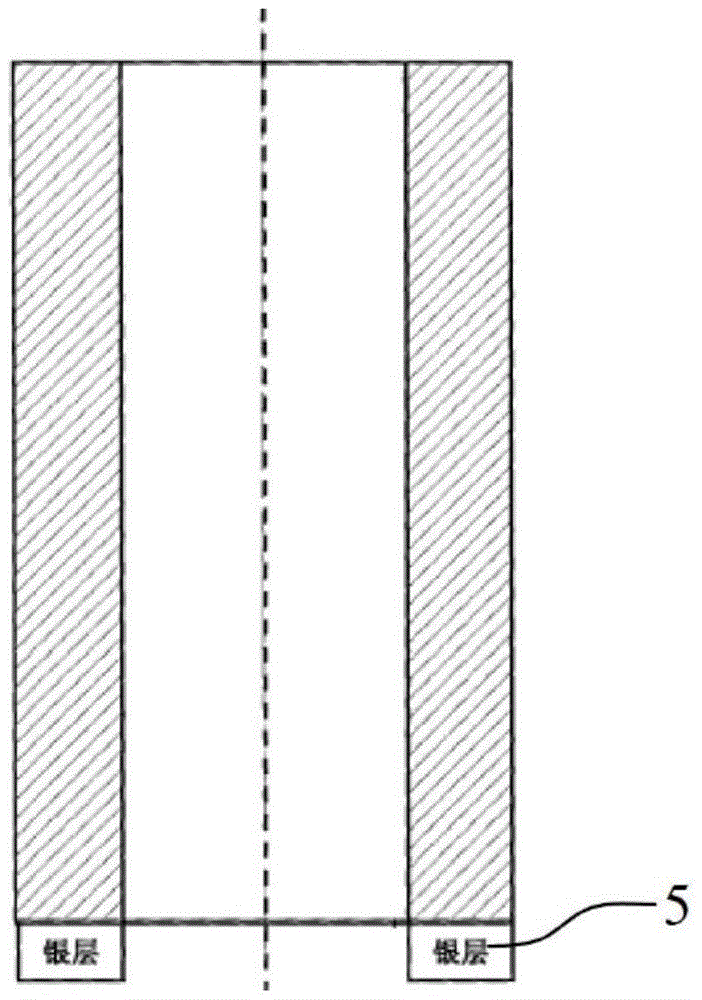

[0037] One end of the dielectric resonator 2 is plated with a silver layer 5, and the other end of the dielectric resonator 2 is welded into the cavity 1;

[0038] The cavity 1 consists of the following components by mass percentage as shown in Table 2:

[0039] Table 2

[0040]

[0041] The relative dielectric constant of the cavity 1 is 9.5.

[0042] The above-mentioned dielectric resonator 2 is composed of the following components by mass percentage:

[0043] 30.5% calcium carbonate with a purity of 97.5%,

[0044] Alumina with a purity of 97.5% 10%,

[0045] 23% neodymium oxide with a purity of 99.5%,

[0046] 36.5% titanium dioxide with a purity of 99.6%....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com