Cake raw material stirrer

A raw material and agitator technology, applied in the field of cake raw material agitator, can solve the problems of wasting time, troublesome operation, heavy workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

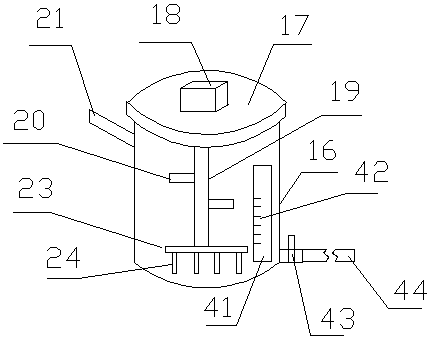

[0010] A kind of cake raw material stirrer, comprises mixing barrel 16, and described mixing barrel 16 is provided with bung 17, and described bung 17 is provided with micromotor 18, and the motor shaft 19 of described micromotor 18 passes through bung 17 Set in the mixing bucket 16, the motor shaft 19 is provided with a stirring blade 20, the bottom end of the motor shaft 19 is provided with a stirring rod 23, and the lower surface of the stirring rod 23 is provided with a plurality of stirring belts 24, so The upper end of the mixing bucket 16 is provided with an upper water pipe 21, the side surface of the mixing bucket 16 is provided with an observation window 41, and the observation window 41 is provided with a scale line 42, and the lower end of the mixing bucket 16 is provided with a discharge port. , A one-way valve 43 is provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com