A method for continuous size classification of graphene materials using packed columns

A classification method, graphene technology, applied in graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems of no way to achieve high-precision separation, complicated steps, complicated operation, etc., and achieve good size separation effect, fine Maximize size separation and achieve the effect of regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

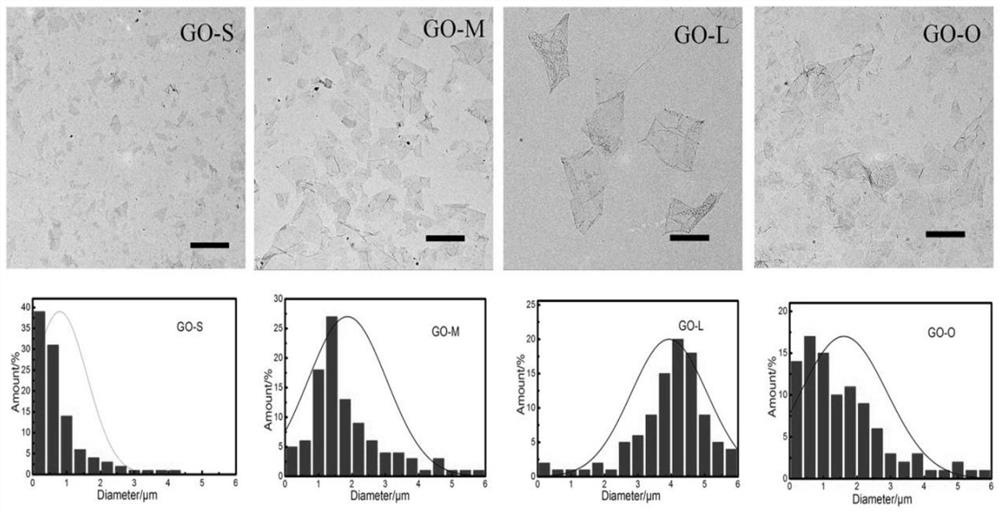

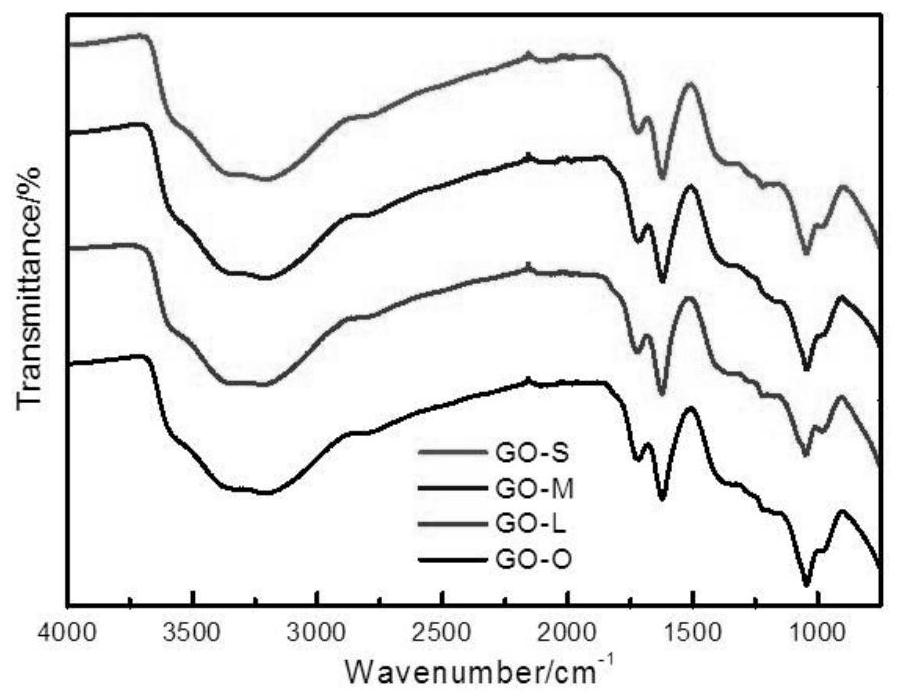

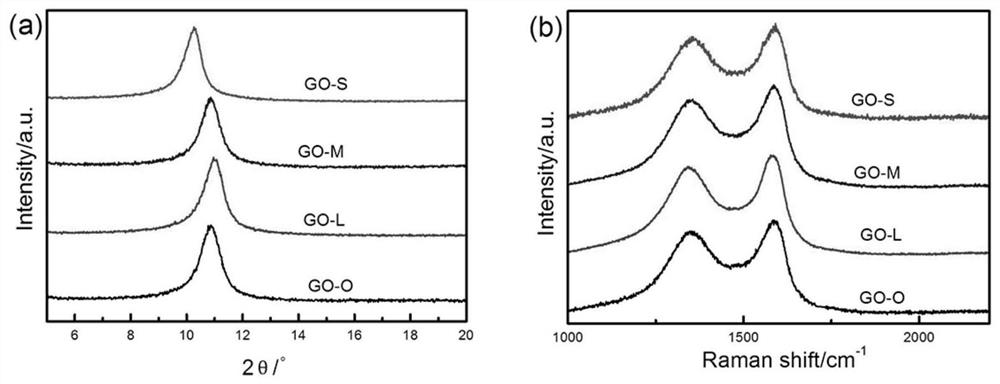

Embodiment 1

[0035] 1) Preparation of graphene oxide (GO): 2000 mesh graphite powder was used to prepare by modified hummers method. Graphite powder (2.0 g) and concentrated sulfuric acid (70 mL) were placed in a 250 mL flask, mechanically stirred (200 rpm) under an ice bath, and then KMnO was added slowly 4 (7.0 g) to keep the temperature of the suspension below 5°C for 30 minutes. Immediately afterwards, the reaction system was transferred to a water bath at 35° C. and vigorously stirred (300 rpm) for about two hours. Then 200 mL of water was added and the solution was stirred for an additional 15 minutes. After that, 5 mL of H was added dropwise 2 o 2 (30%), the solution turned from dark brown to yellow. The mixture was filtered and washed with 5% aqueous HCl (3 times 50 mL) to remove metal ions, and washed with water until neutral. The resulting solid was dispersed in water to form 2mg mL -1 suspension.

[0036] 2) Grading graphene oxide with a silica gel column: Rinse the irreg...

Embodiment 2

[0050] 1) Preparation of graphene oxide (GO): 200 mesh graphite powder was used to prepare by modified hummers method. Graphite powder (2.0 g) and concentrated sulfuric acid (70 mL) were placed in a 250 mL flask, mechanically stirred (200 rpm) under an ice bath, and then KMnO was added slowly 4 (7.0 g) to keep the temperature of the suspension below 5°C for 30 minutes. Immediately afterwards, the reaction system was transferred to a water bath at 35° C. and vigorously stirred (300 rpm) for about two hours. Then 200 mL of water was added and the solution was stirred for an additional 15 minutes. After that, 5 mL of H was added dropwise 2 o 2 (30%), the solution turned from dark brown to yellow. The mixture was filtered and washed with 5% aqueous HCl (3 times 50 mL) to remove metal ions, and washed with water until neutral. The resulting solid was dispersed in water to form 2mg mL -1 suspension.

[0051] 2) Grading graphene oxide with a ceramic particle column: Rinse the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com