A kind of purification method of sugammadex sodium

A technology of sugammadex sodium and a purification method, which is applied in the field of purification of muscle relaxant antagonist sugammadex sodium, can solve the problems such as the difference in molecular weight and molecular size between impurities and sugammadex sodium, and achieves good industrialization prospects. , low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: the pretreatment of active carbon

[0056] Under nitrogen protection, take Special Egret (TOKUSEI SHIRASAGI) 5 grams of activated carbon and 100ml of purified water are added to a 250ml three-necked bottle, which is equipped with a mechanical stirrer and connected to a vacuum device. Under stirring, vacuumize and replace with nitrogen to maintain the nitrogen atmosphere, and heat the water / activated carbon mixture in the bottle to boiling. After keeping boiling for 0.5 hour, stop heating and cool down to room temperature. Nitrogen pressure filtration, the obtained filter cake is pretreated activated carbon, which is filled with nitrogen and stored for later use.

Embodiment 2

[0057] Embodiment 2: the pretreatment of active carbon

[0058] Under nitrogen protection, take egret Add 5 grams of A (SHIRASAGIA) activated carbon and 100ml of purified water into a 250ml three-necked bottle, which is equipped with a mechanical stirrer and connected to a vacuum device. Under stirring, vacuumize and replace with nitrogen to maintain the nitrogen atmosphere, and heat the water / activated carbon mixture in the bottle to boiling. After keeping boiling for 0.5 hour, stop heating and cool down to room temperature. Nitrogen pressure filtration, the obtained filter cake is pretreated activated carbon, which is filled with nitrogen and stored for later use.

Embodiment 3

[0059] Example 3: Purification of crude sugammadex sodium.

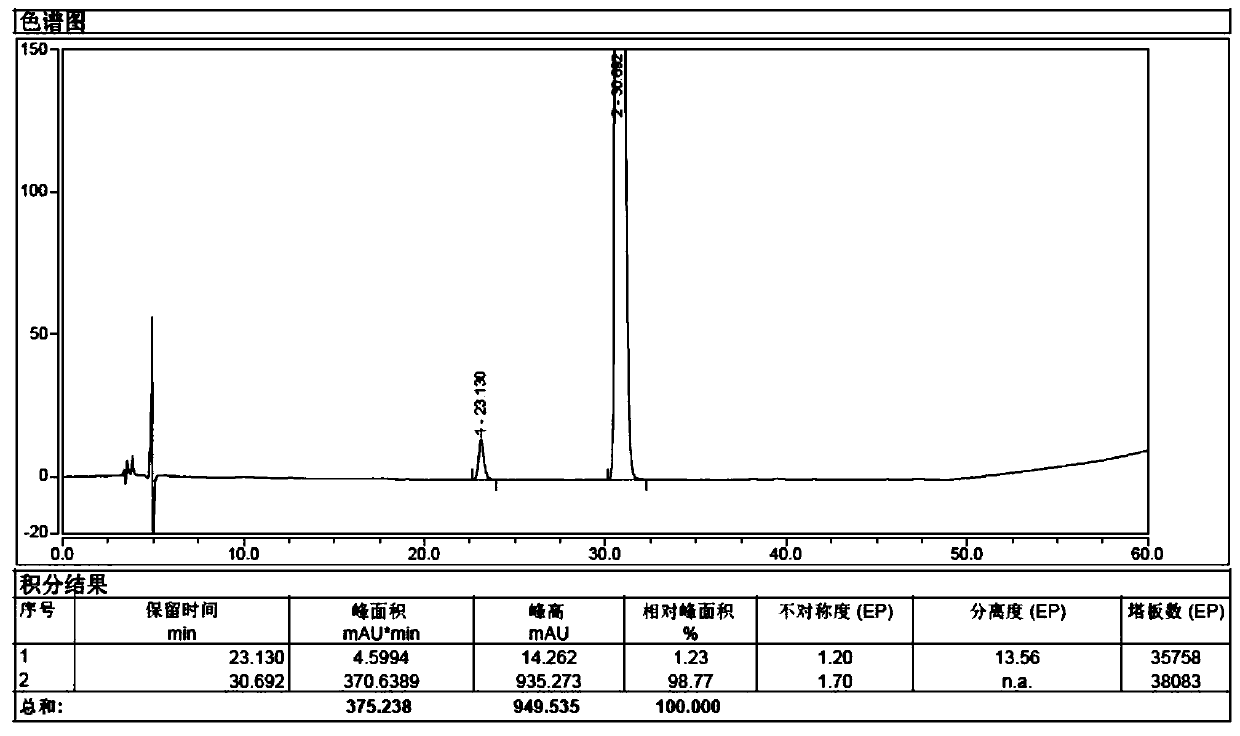

[0060] Add 10g of sugammadex sodium crude product into a 250ml three-neck bottle, dissolve in 50ml of freshly boiled cold water In, under the protection of nitrogen, add the pretreated prepared in Example 1 Special Egret (TOKUSEI SHIRASAGI) activated carbon 1g, stirred and adsorbed for 2 hours. The activated carbon was filtered out, and the obtained aqueous solution was concentrated to obtain 9.2 g of pure sugammadex sodium, with a purity of 100.0% (sugammadex sodium+monohydroxy sugammadex sodium). The HPLC diagram is shown in figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com