Spray arm and cleaning machine

A spray arm and spray hole technology, applied in the field of machinery, can solve the problems of complex connection structure, manufacturing, assembly, and cost disadvantages of the spray arm or spray arm, and achieve a simple structure, low cost, and few parts used Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0022] Combine below Figure 1 to Figure 4 The technical solutions provided by the present invention are described in more detail.

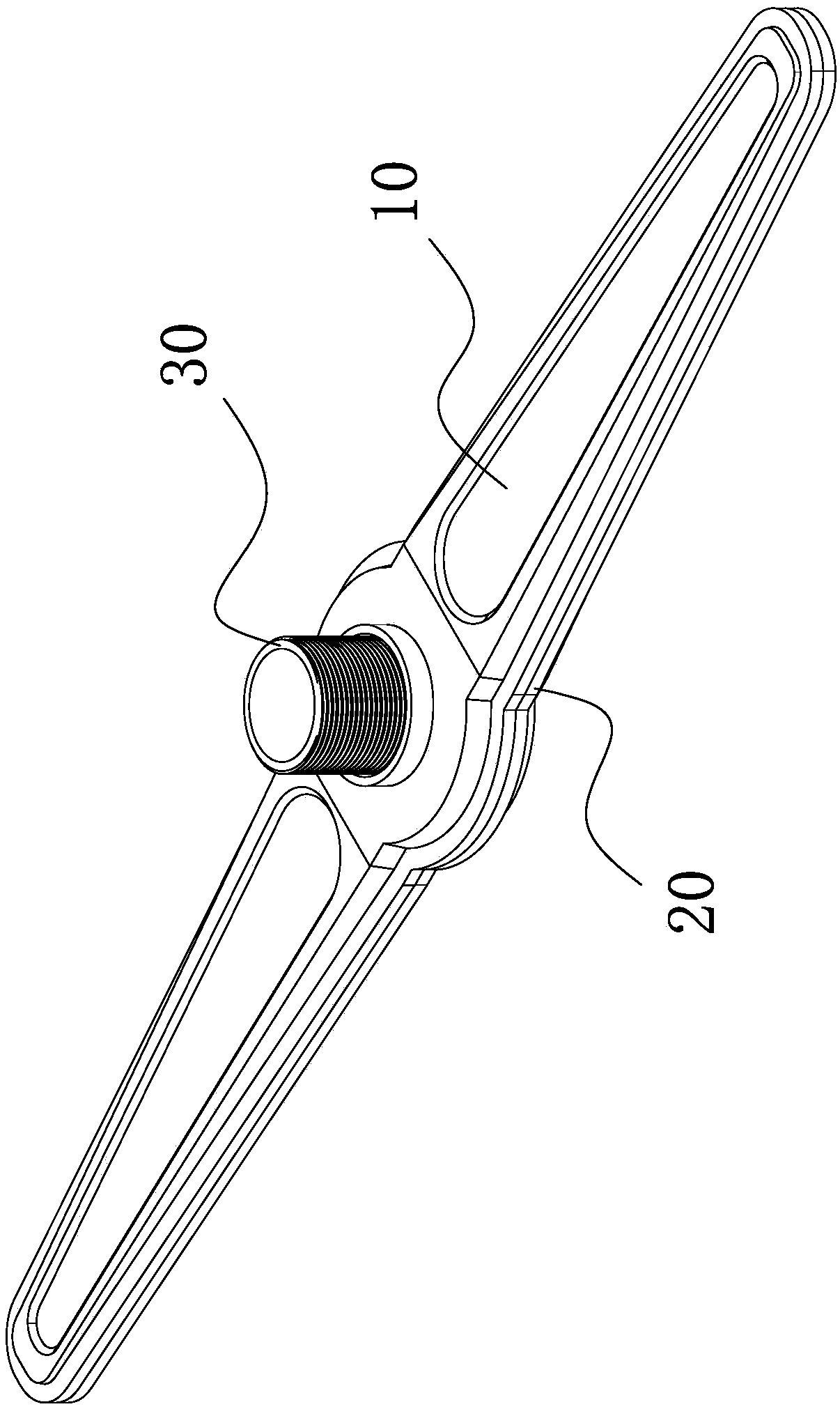

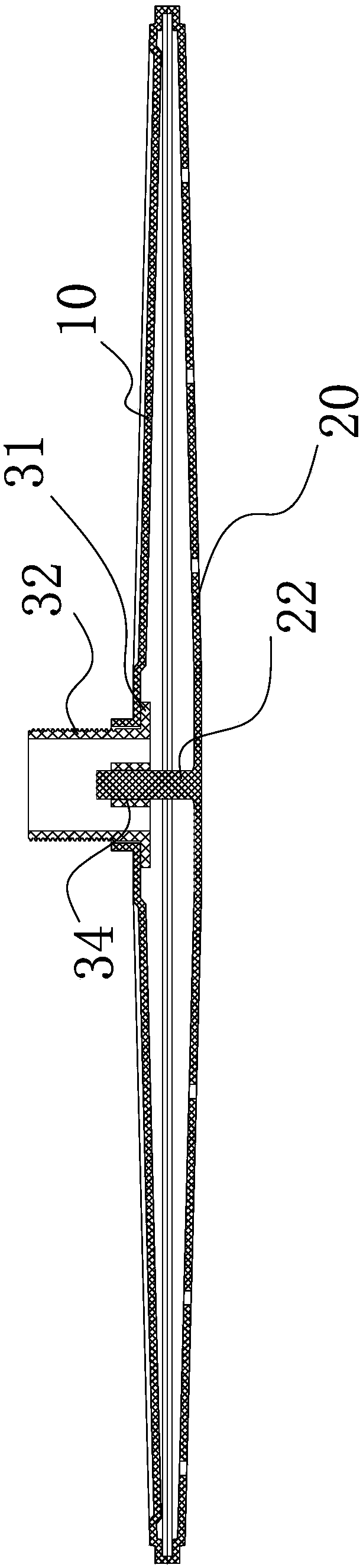

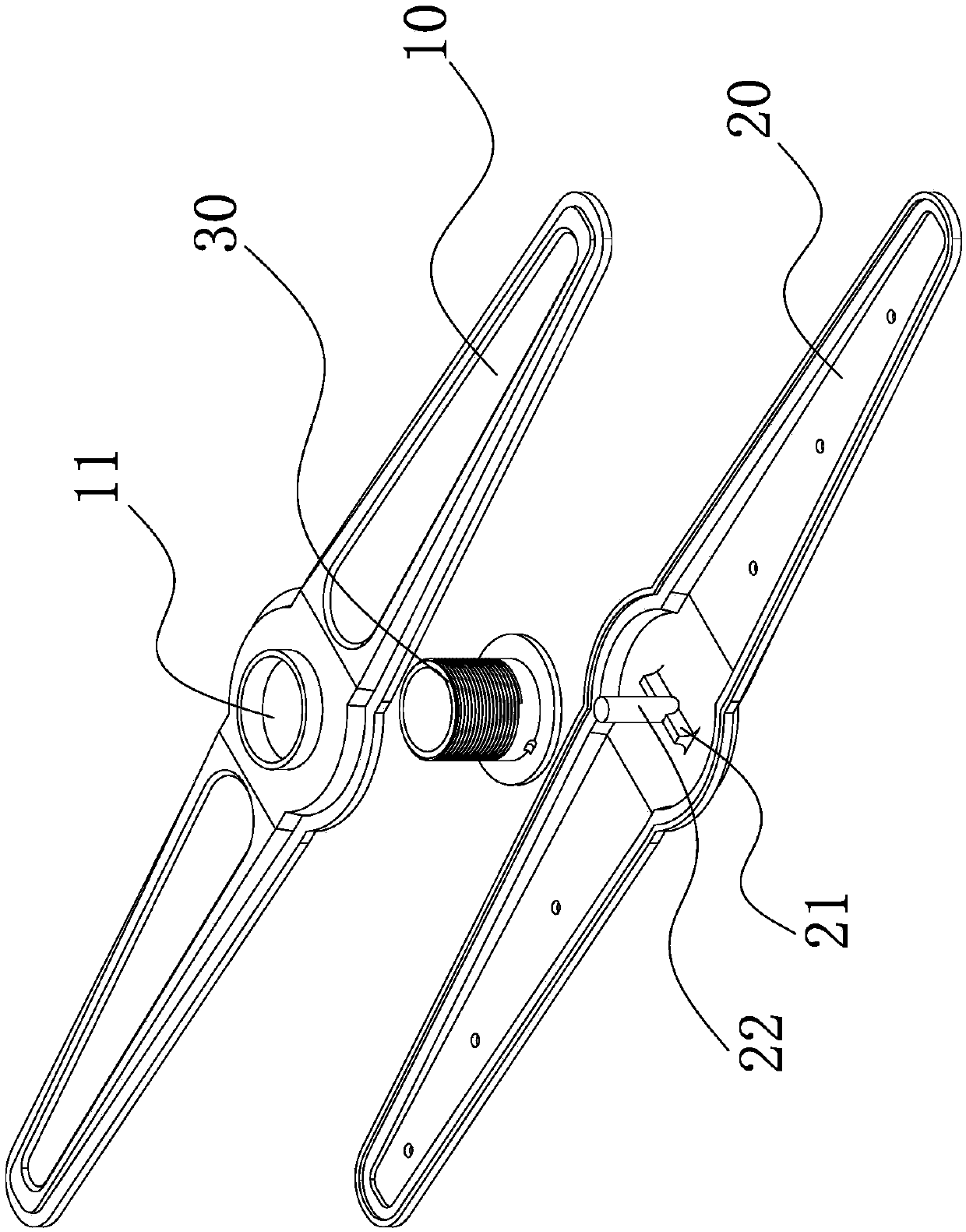

[0023] like Figure 1 to Figure 4 Shown, this spray arm spray arm includes:

[0024] The upper part 10 of the spray arm is provided with a through hole 11 in the middle;

[0025] The lower part 20 of the spray arm, the middle part is provided with a protrusion 21, and the lower part 20 of the spray arm is provided with a spray hole;

[0026] The connecting piece 30 includes a wider connecting part 31 and a narrower fixing part 32, the connecting part 31 is located between the upper part 10 of the spray arm and the lower part 20 of the spray arm, and the fixing part 32 passes through the spraying The through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com