Stirring device for lubricating oil production and processing

A technology of stirring device and lubricating oil, which is applied to mixers with rotary stirring devices, accessories of mixers, transportation and packaging, etc., can solve problems such as affecting people's use, damage to pumping pumps, affecting the mixing efficiency of lubricating oil, etc., and achieves practicability. Strong, convenient for production and processing, and the effect of improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

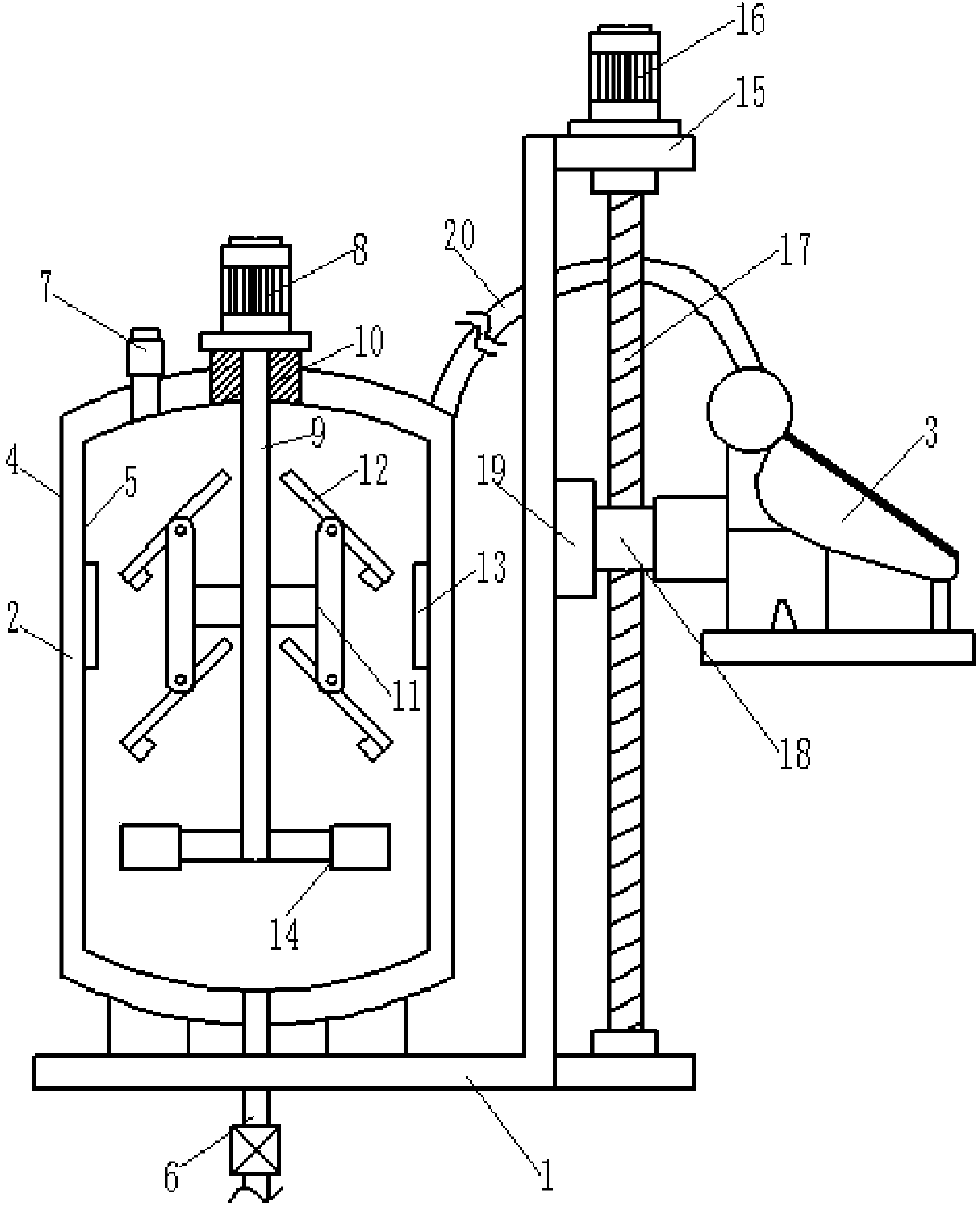

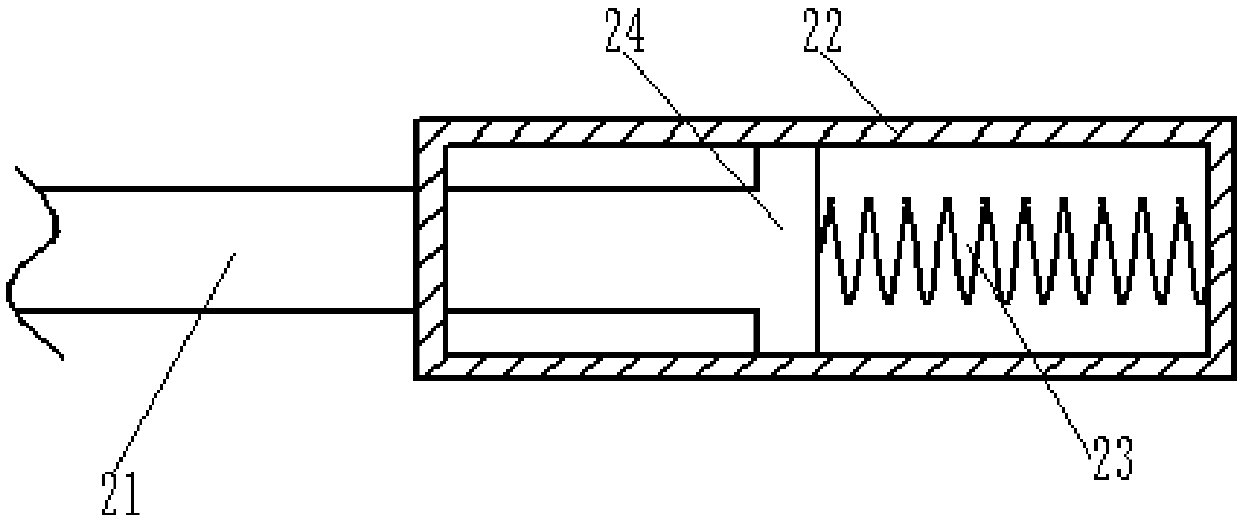

[0020] Such as figure 1 and figure 2 As shown, a stirring device for lubricating oil production and processing includes a fixed bracket 1, a mixing bucket 2 and a solar heater 3; the fixed bracket 1 is fixedly connected with a mixing bucket 2, and the top of the mixing bucket 2 is A driving motor 8 is fixedly connected, and the mixing tank 2 is mainly composed of an outer shell 4 and an inner shell 5, and the outer shell 4 and the inner shell 5 form an insulating cavity. The mixing tank 2 is provided with a rotating shaft 9, which is connected to the The above-mentioned drive motor 8 is connected, and the T-shaped support frame 11 is fixedly connected on the described rotating shaft 9, and the upper and lower ends of the T-shaped support frame 11 are hinged with stirring rods 12, and the bottom of the described stirring rod 12 is A magnetic block is fixedly connected, and a permanent magnet 13 is fixedly connected to the inner wall of the mixing bucket 2, the permanent magne...

Embodiment 2

[0023] Such as figure 1 Shown, a kind of stirring device that lubricates production and processing is used, on the basis of embodiment 1, described fixed bracket 1 upper and lower ends are fixedly connected with fixed plate 15, and described fixed plate 15 is fixedly connected with adjusting Motor 16, a rotating shaft 17 is rotatably connected between the fixed plates 15, the top of the rotating shaft 17 is connected to the adjusting motor 16, and the bottom of the rotating shaft 17 is rotatably connected to the fixed plate 15, and Threads are uniformly distributed on the rotating shaft 17, and a socket 18 is sleeved on the rotating shaft 17, and the socket 18 is threadedly connected with the rotating shaft 17, and the socket 18 is fixedly connected with Sliding block 19, sliding block 19 is slidably connected with the fixed bracket 1, and the solar heater 3 is fixedly connected to the sleeve 18, and the solar heater 3 is insulated with the mixing tank 2 through the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com