Cleaning technique of underlayer for PECVD film coating

A substrate and cleaning technology, which is applied in the field of PECVD coating substrate cleaning technology, can solve the problems of acetone toxicity, complicated troubles, and physical injuries, and achieve the effects of reducing troubles, reducing physical injuries of workers, and simple heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

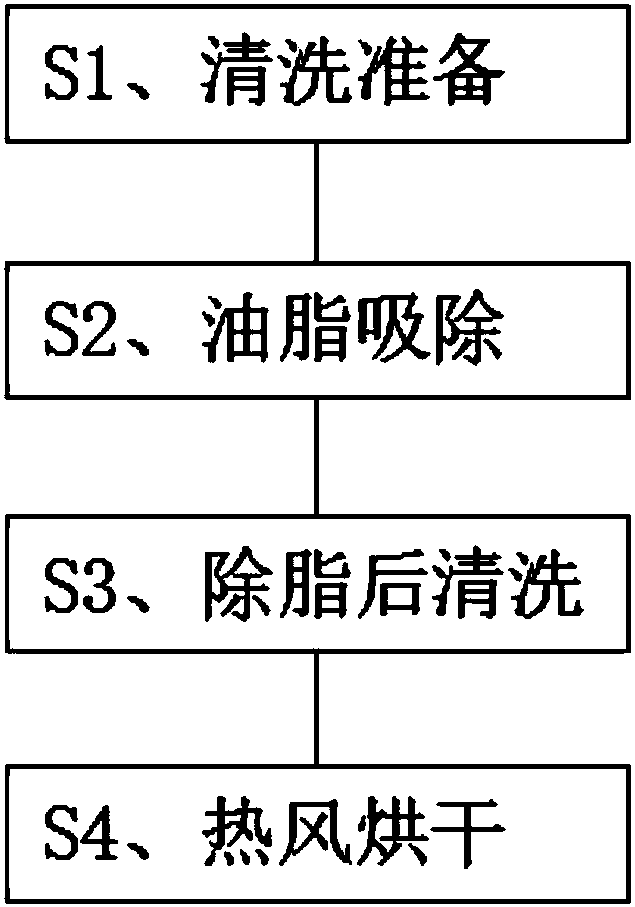

Method used

Image

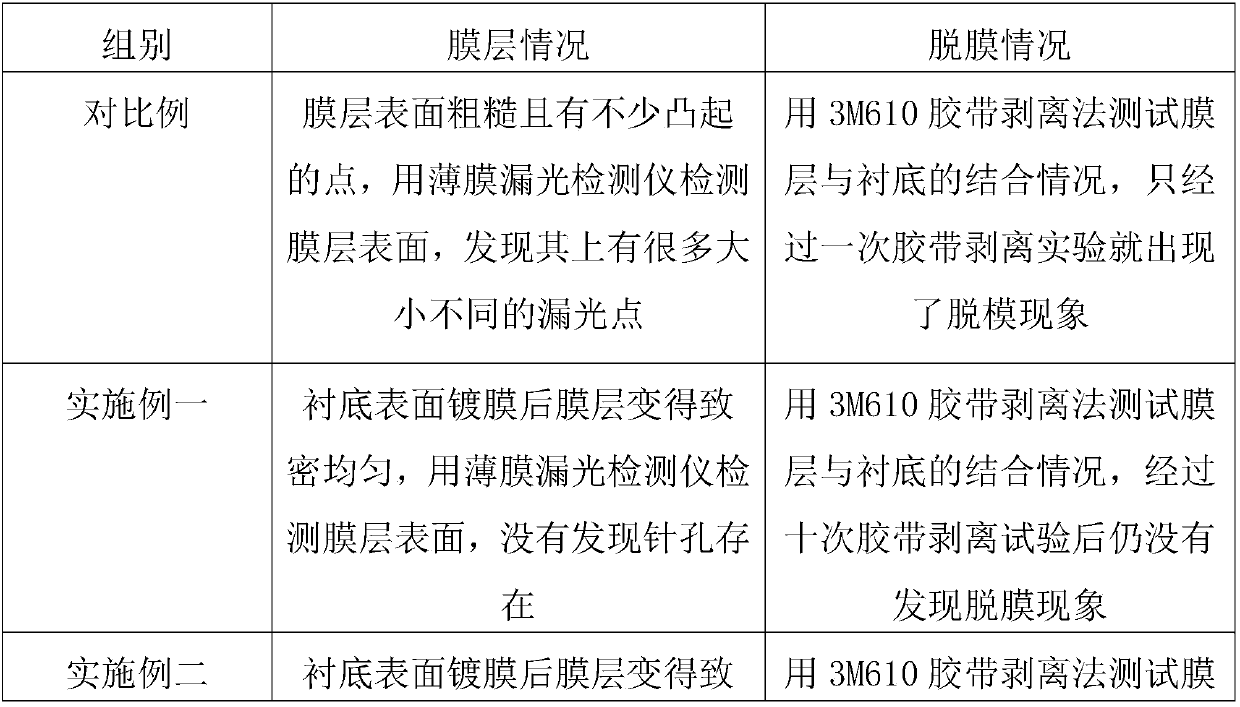

Examples

Embodiment 1

[0031] Apply the cleaning process provided by the present invention to clean the coating substrate, and then perform coating on the substrate. The specific steps are as follows:

[0032] 1. First put the substrate for coating into the deionized water tank and soak for 2 minutes;

[0033] 2. Take out the soaked substrate from the deionized water, and then treat the substrate with the same heating temperature and the same heating time 5 times, each time use absorbent paper to completely wrap the substrate, and use Heat treatment in the oven, and the absorbent paper after each heating treatment needs to be removed and replaced with a new absorbent paper. The heating temperature of the heating treatment is 80°C, and the heating time of each heating treatment is 5 minutes;

[0034] 3. Take out the substrate after three times of heat treatment, and directly spray and rinse the substrate with ultrapure water, and spray each surface of the substrate for 30 seconds;

[0035] 4. Finall...

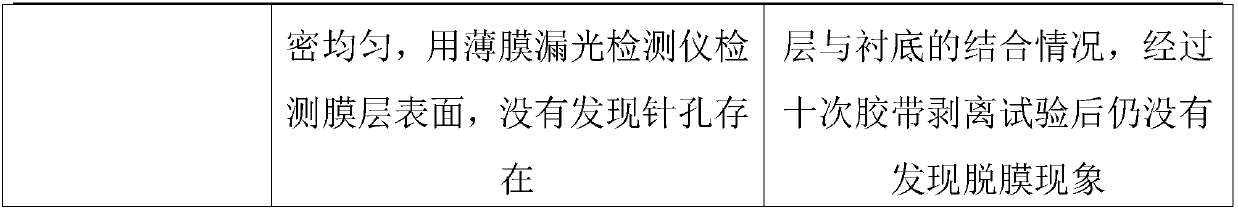

Embodiment 2

[0038] Apply the cleaning process provided by the present invention to clean the coating substrate, and then perform coating on the substrate. The specific steps are as follows:

[0039] 1. First put the substrate for coating into the deionized water tank and soak for 1min;

[0040] 2. Take out the soaked substrate from the deionized water, and then treat the substrate with the same heating temperature and the same heating time three times. Each time, use absorbent paper to completely wrap the substrate, and use The oven is used for heat treatment. After each heat treatment, the absorbent paper needs to be removed and replaced with a new one. The heating temperature of the heating treatment is 50°C, and the heating time of each heating treatment is 3 minutes;

[0041] 3. Take out the substrate after three times of heat treatment, and directly spray and rinse the substrate with ultrapure water, and spray each surface of the substrate for 30 seconds;

[0042] 4. Finally, the ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com