Post manufacture procedure machining device for flexible sheet-like rolled materials

A processing device and sheet-like technology, which is used in the cutting of textile materials, removing smoke and dust, textiles and papermaking, etc., can solve the problems of low efficiency of removing surface hairiness and floating dust, lack of formaldehyde removal and disinfection devices, and inconvenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

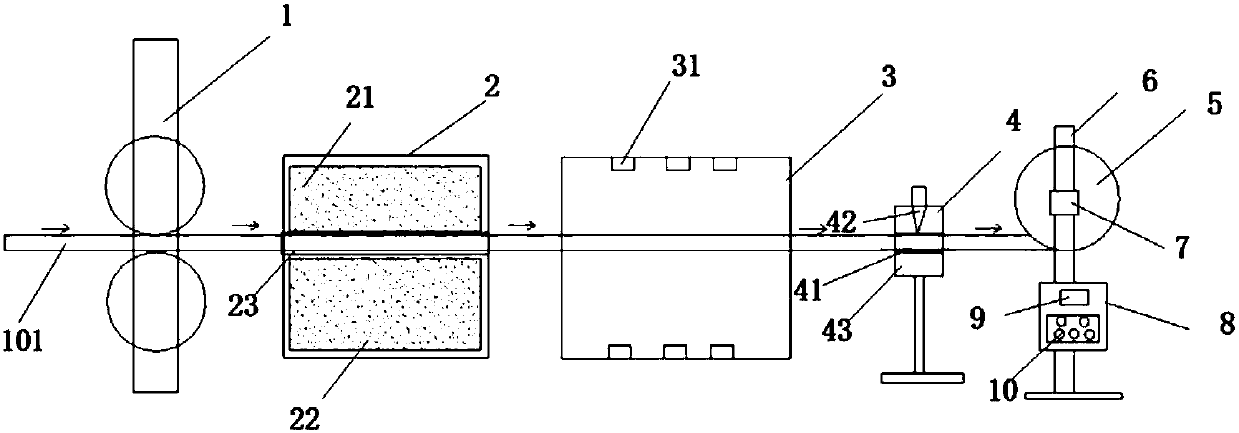

[0018] Embodiment: A post-process processing device for a flexible sheet-like coil, based on the moving direction of the flexible sheet-like coil 101, sequentially includes a hair removal device 1, a formaldehyde adsorption box 2, an ultraviolet disinfection box 3, and an automatic cutting device 4 And collecting cylinder 5, described depilatory device comprises two depilatory cylinders that are arranged at intervals up and down, the inside of described formaldehyde adsorption box is provided with upper and lower adsorption layer 21,22, leaves between described upper and lower adsorption layer The gap 23 for the flexible sheet-like coil to pass through, the inner upper and lower ends of the ultraviolet disinfection box are equipped with ultraviolet germicidal lamps 31, and the automatic cutting device is provided with a through opening for the flexible sheet-like coil to pass through 41. The collection drum is rotatably mounted on the support frame 6, the motor 7 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com