O-shaped ring assembly device

An assembly device and O-ring technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor assembly effect, poor quality, and high labor intensity of operators, and achieve high assembly efficiency and reduce labor. Strength, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

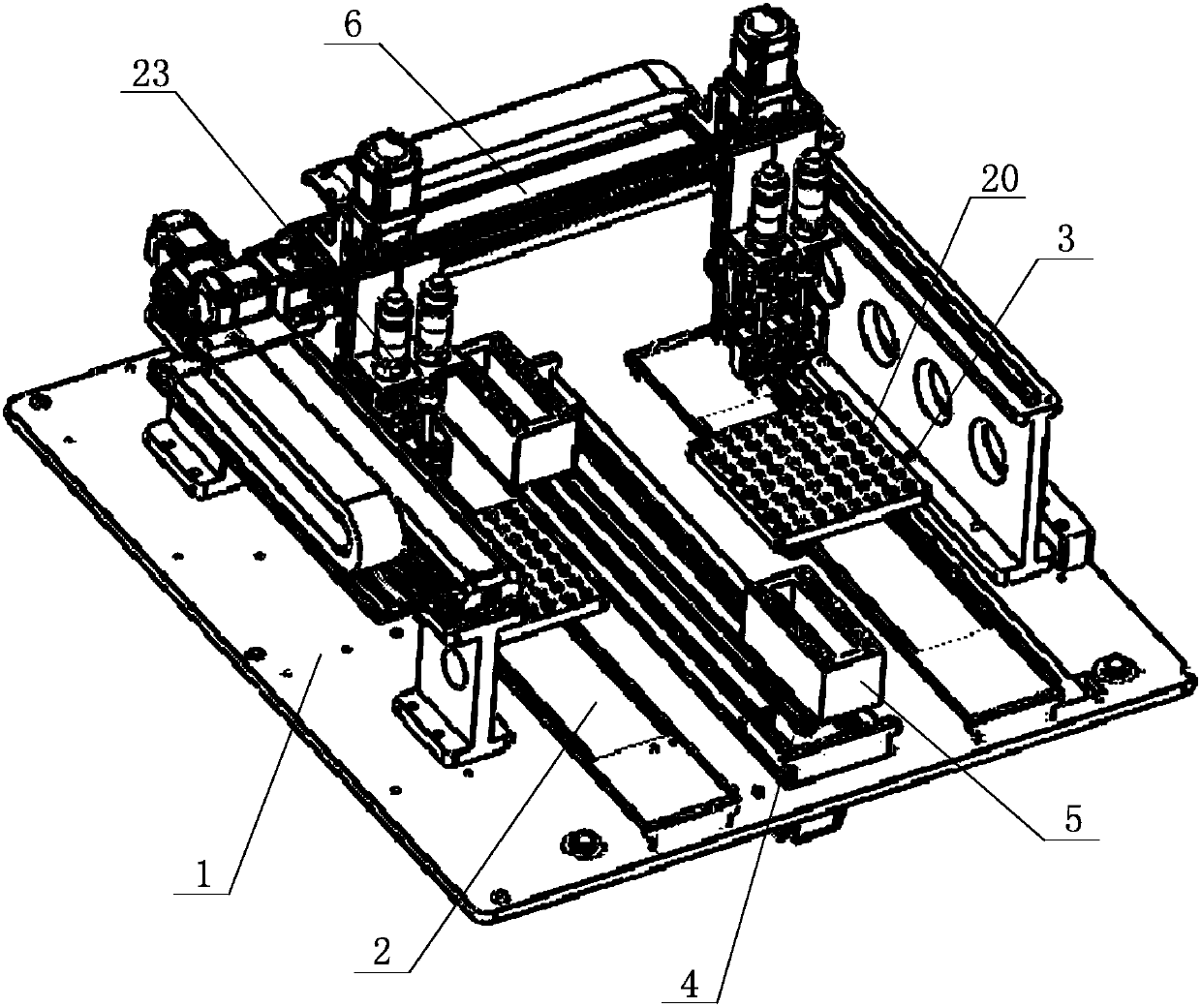

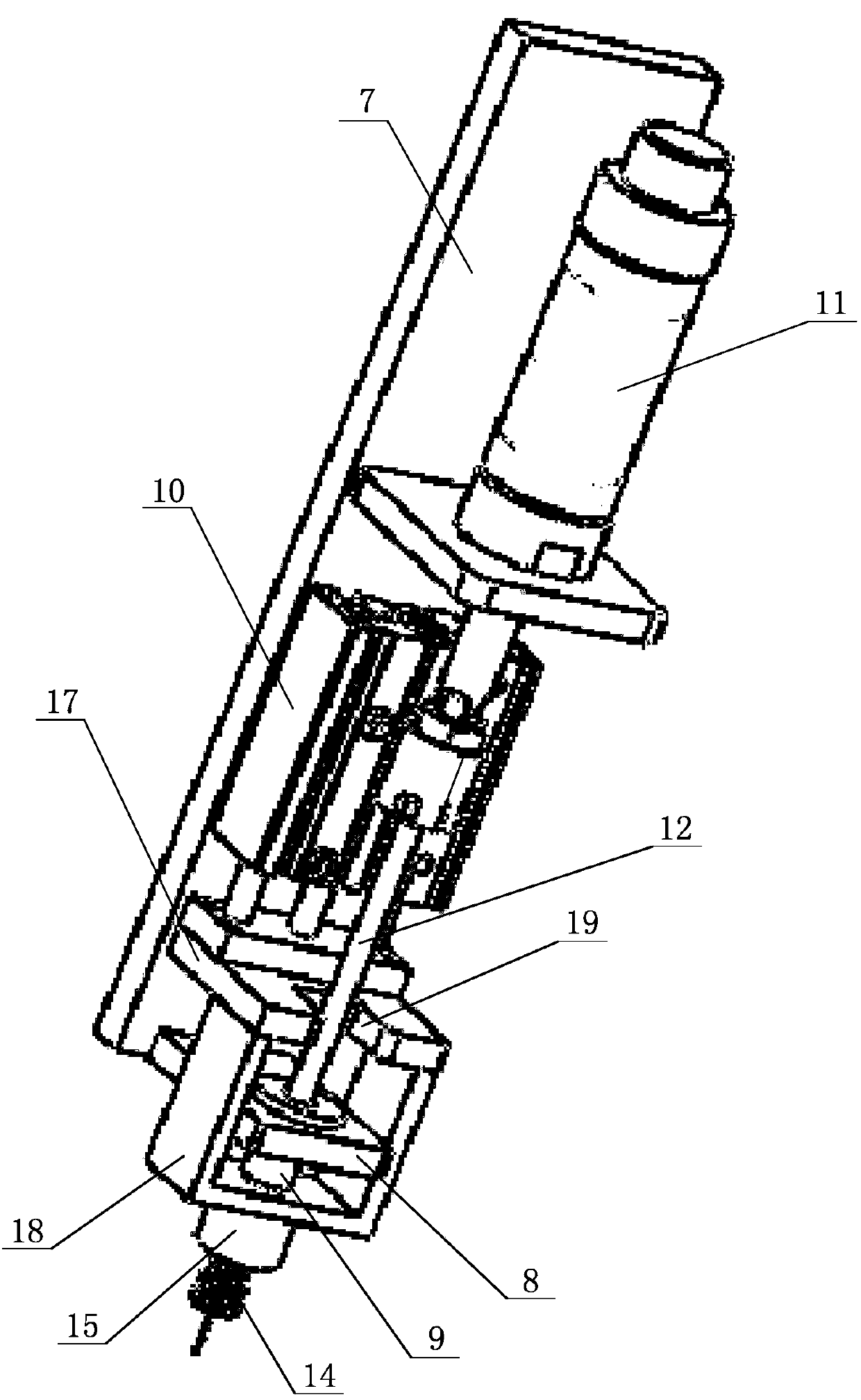

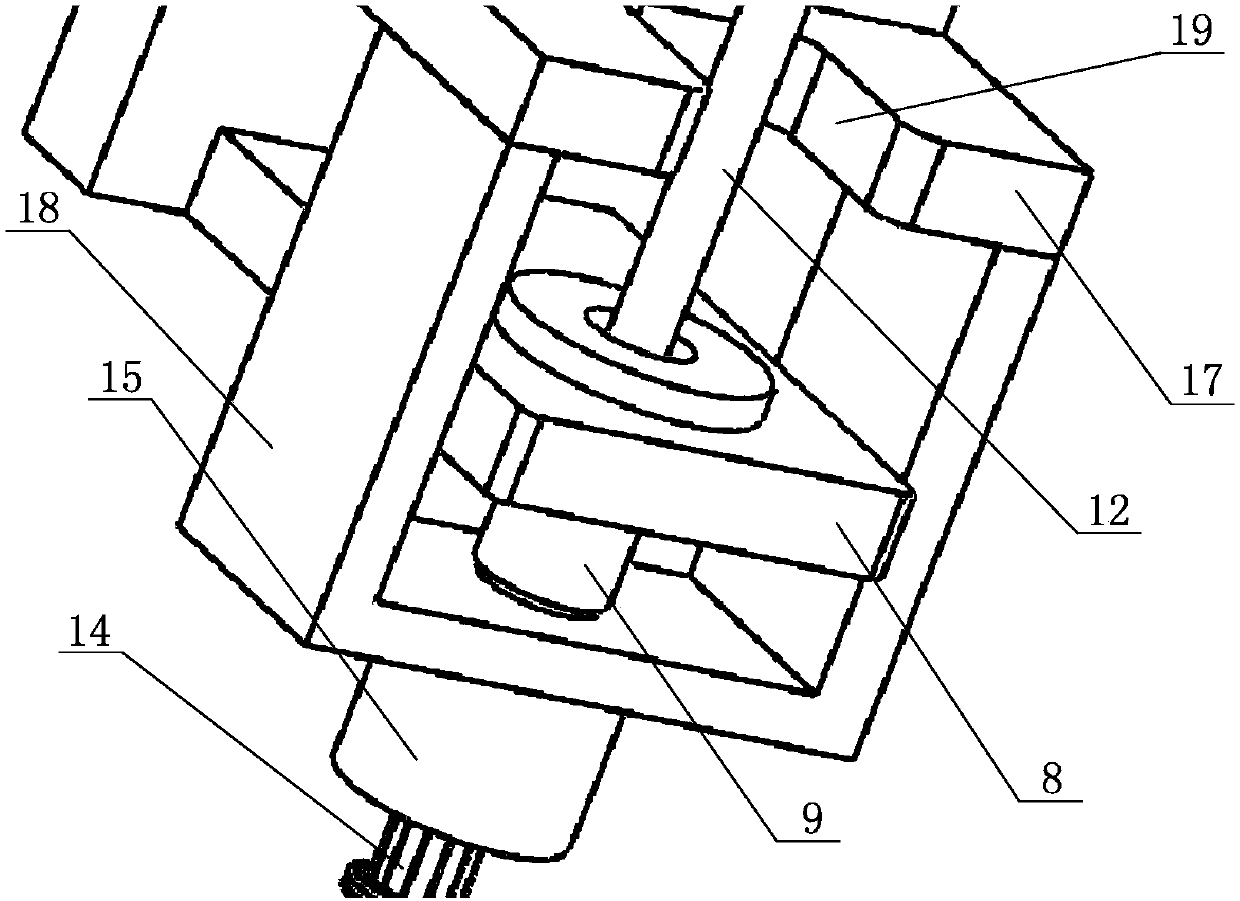

[0022] Embodiment one: see Figure 1~5 As shown, an O-ring assembly device includes a frame 1, a product feeding device arranged on the frame 1, an O-ring feeding device and an assembly device, and the product feeding device includes a product feeding slide rail 2 and the product feeding tray 3 that is slidably arranged on the product feeding slide rail 2, the O-ring feeding device includes a slide rail 4 and a feed tray 5 that is slidably arranged on the slide rail 4, and the slide rail 5 is arranged on the side of the product feeding slide rail 2, and the slide rail 4 is arranged parallel to the product feeding slide rail 2; the assembly device includes a driving mechanism 6 and is installed on the driving mechanism 6 The assembly mechanism 23, the assembly mechanism includes a vertical plate 7, a mounting plate 8, a material grab 9, a first telescopic cylinder 10, a second telescopic cylinder 11 and a strut 12, and the grab material 9 is installed on the installation On th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap