Method for 3D printing of surface of concrete wall body and application of method

A concrete wall and 3D printing technology, which is applied in the direction of ceramic forming machines, manufacturing tools, additive processing, etc., can solve the problems of poor decoration effect, uneven wall surface, unsightly appearance, etc., achieve short setting time and improve smoothness The effect of high speed and strong expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

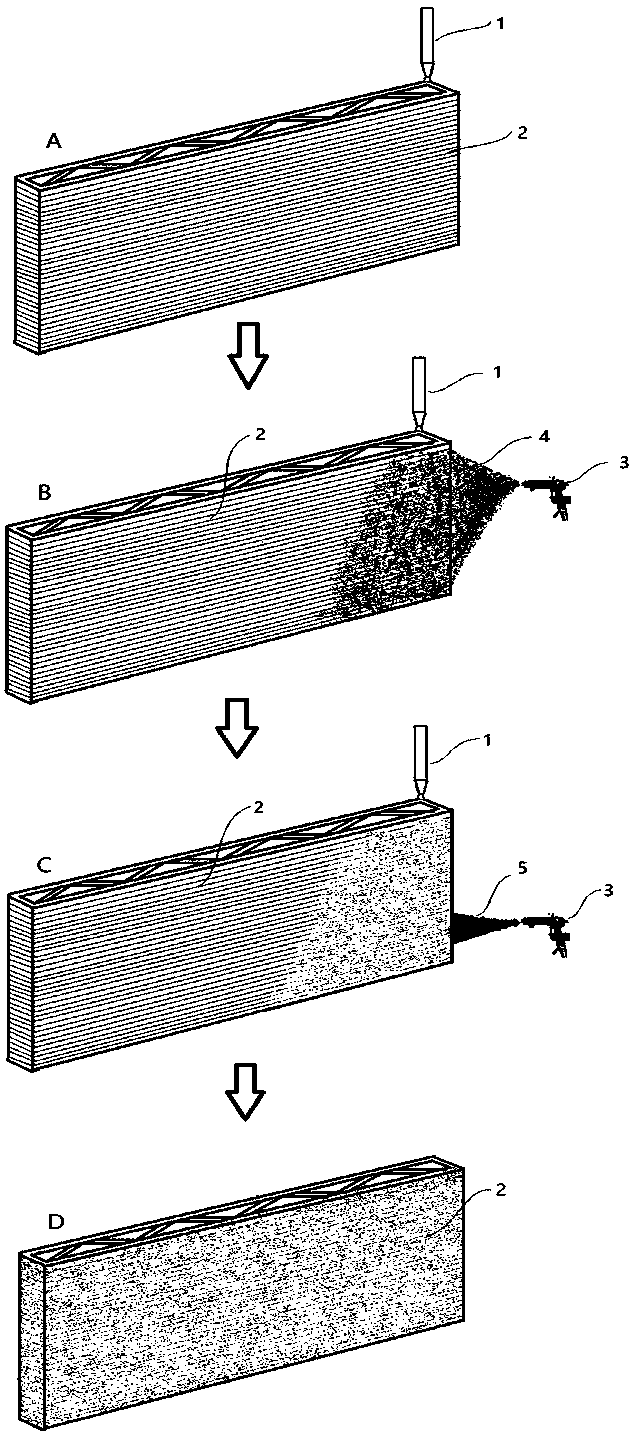

[0045] The method of 3D printing the surface of the concrete wall, the specific construction steps are:

[0046] (1) Clean the foundation wall, arrange the bricks to lay down the bottom, set the wall control line, and assemble the bricks;

[0047] (2) Use the 3D printing head to spray pre-mixed concrete to print the wall; 3D printing concrete includes sulphoaluminate cement, red sintered colored sand, water and water reducing agent.

[0048] (3) Complete the printing of the wall surface.

[0049] Step B, spraying high-concentration admixture on the surface of the wall that has just been printed, wherein the admixture is applied using a spray gun, and the retarder is dispersed in the form of mist droplets;

[0050] Step C, after the surface of the printed concrete wall itself reaches the final setting time, use the high-pressure water column 5 sprayed from the spray gun to wash the wall surface sprayed with retarder, so that the uncondensed cement paste on the surface will be ...

Embodiment 3

[0053] The specific construction steps are:

[0054] (1) Clean the foundation wall, set up the integral formwork of the cast-in-place wall, and the concrete cast-in-place wall;

[0055] (2) Use the 3D printing head to spray pre-mixed concrete to print the wall; 3D printing concrete includes ordinary Portland cement, multi-color mixed fine pebbles, water and water reducing agent.

[0056] (3) Complete the printing of the wall surface.

[0057] Step B, spraying high-concentration admixture on the surface of the wall that has just been printed, wherein the admixture is applied using a spray gun, and the retarder is dispersed in the form of mist droplets;

[0058] Step C, after the surface of the printed concrete wall itself reaches the final setting time, use the high-pressure water column 5 sprayed from the spray gun to wash the wall surface sprayed with retarder, so that the uncondensed cement paste on the surface will be lost and exposed. Low story hardened cement color and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com