Printing method combining gravure printing and digital printing of printing device and print

A technology of digital printing and printing method, applied in the field of printing and dyeing, can solve the problems of reducing printing quality, misalignment of gravure printing pattern and digital printing pattern, and failing to solve the problem of alignment of gravure printing pattern and digital printing pattern, etc., and achieves printing speed. Fast, stable color difference, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Reference will now be made in detail to the embodiments depicted in the accompanying drawings. In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. However, it will be understood by those skilled in the art that the present invention may be practiced without these specific details.

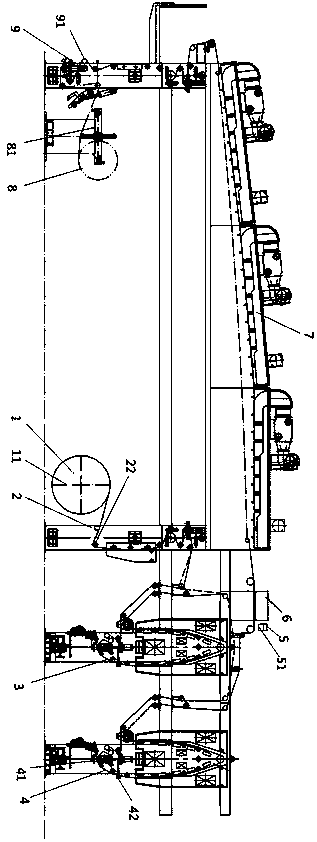

[0039] like figure 1 As shown, the printing device in this embodiment includes: a feeding unit 1, a feeding traction unit 2, an oiling unit 3, a gravure printing unit 4, a detection unit 5, a digital printing unit 6, a drying tunnel 7, and a winding unit 8 and receiving traction unit 9. The above-mentioned printing device is only an example, and the printing device can be compared with figure 1 Have more or fewer components, or have a different configuration of components. The above-mentioned discharging unit 1, discharging traction unit 2, oiling unit 3, gravure printing unit 4, detection u...

Embodiment 2

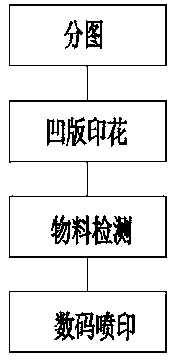

[0053] see image 3 , the printing method in the present embodiment, it utilizes the printing device among the embodiment 1, comprises the following steps:

[0054] 1) Divide the image: decompose the target pattern into gravure printing pattern and digital printing pattern;

[0055] 2) gravure printing; carry out gravure printing on the material through the gravure printing unit 4 to obtain a gravure printing pattern;

[0056] 3) Material detection: through the detection unit 5, the position information of the material is detected, and the position information can be the position of the flower back, the length of the flower back, etc.;

[0057] 4) Digital printing: According to the position information of the detected material, the digital printing unit 6 is used for printing, and according to the position information of the detected material, the speed of printing and the target graphic of the printing are adjusted to obtain Digital printing pattern.

[0058] In this embod...

Embodiment 3

[0063] see Figure 4 , the printed matter in this embodiment has a gravure printing pattern 10 and a digital printing pattern 20, the gravure printing pattern 10 and the digital printing pattern 20 are combined in the form of overprinting, and the gravure printing pattern 10 and the digital printing pattern 20 adopt the described Utilize the printing method of embodiment 2 to form.

[0064] The printed matter in this embodiment is provided with several position identification points 30 .

[0065] The printed matter in this embodiment can be paper or textiles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com