Cosmetic packaging bottle

A technology for packaging bottles and cosmetics, applied in the field of cosmetic packaging bottles, can solve problems such as waste of resources, damage from extrusion, inconvenience in use, etc., and achieve the effects of convenient use, avoiding pollution and waste, and avoiding extrusion deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

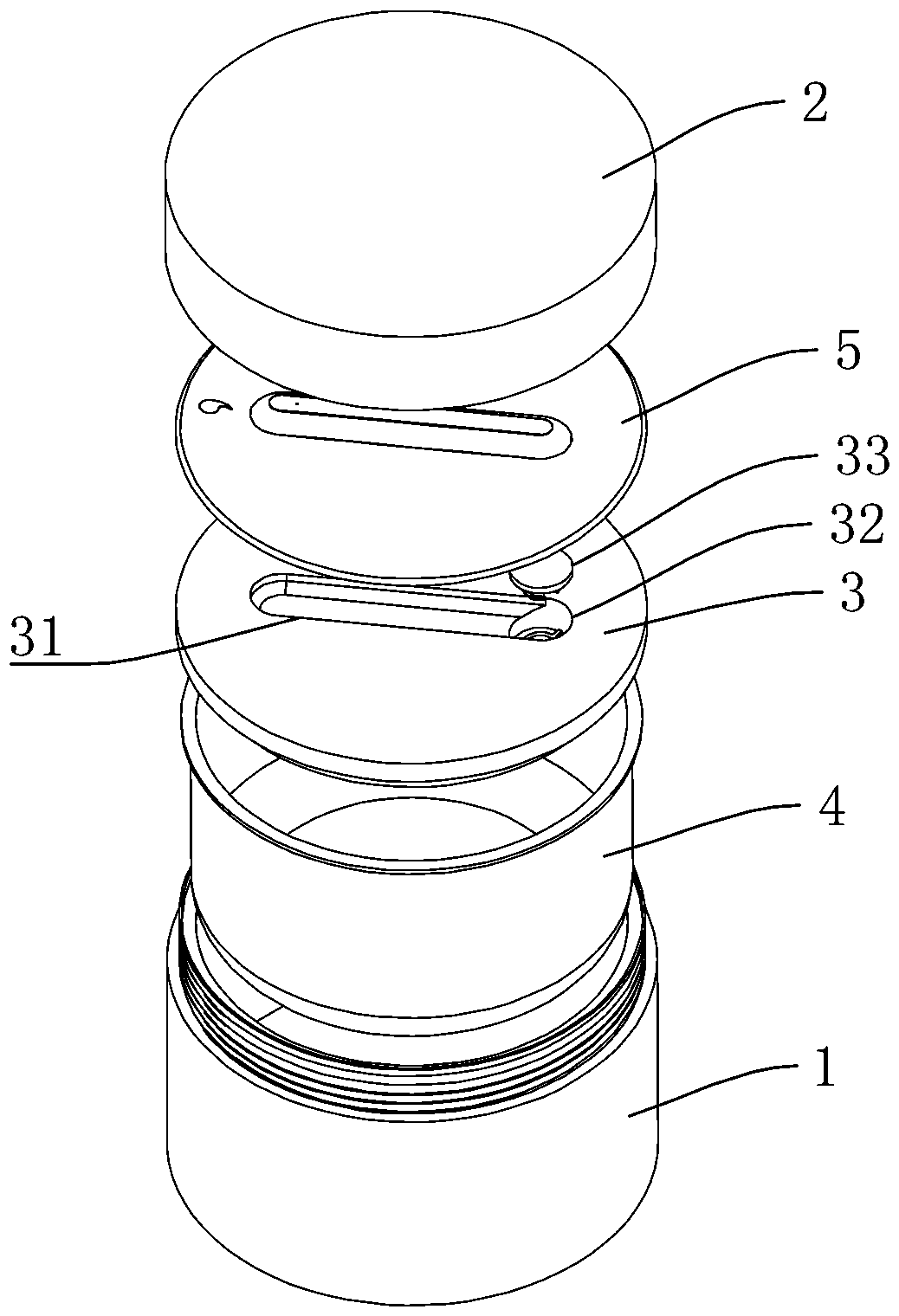

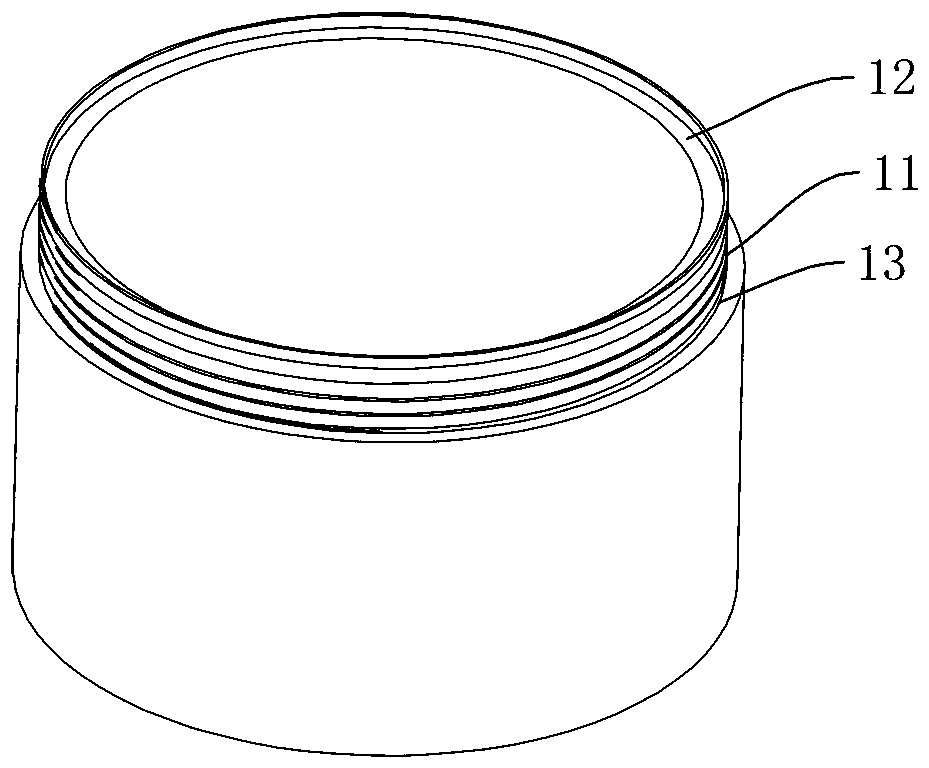

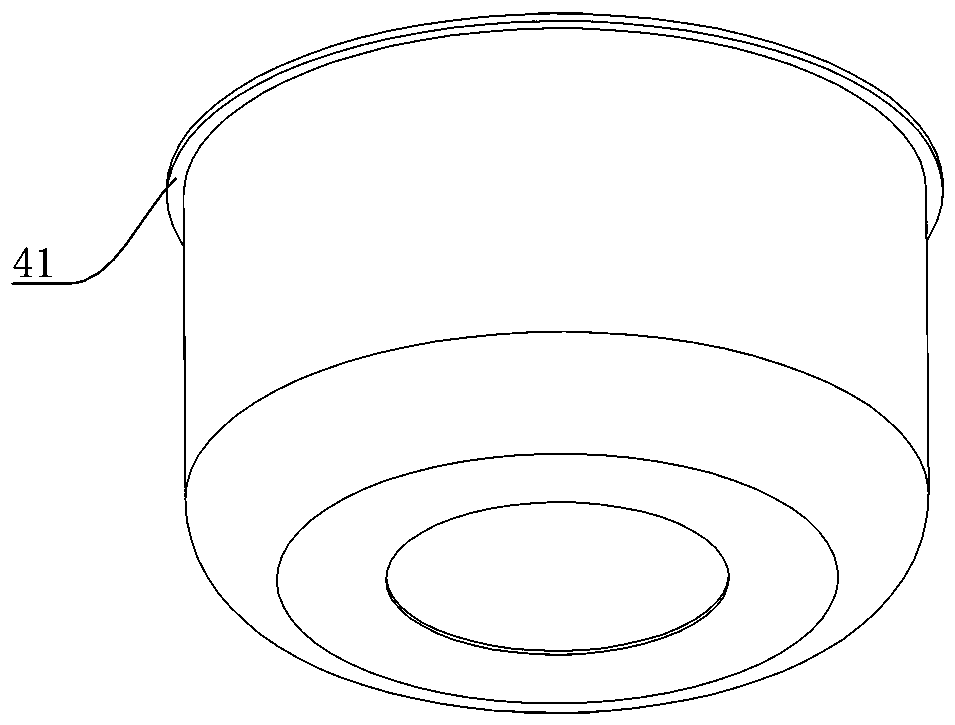

[0021] A cosmetic packaging bottle, such as figure 1 As shown, including the bottle body 1 and the cover body 2, both the bottle body 1 and the cover body 2 are made of rigid materials, which can avoid extrusion deformation during transportation, and are more beautiful in appearance. An external thread 11 is provided, and an internal thread 21 cooperating with the external thread 11 is provided on the cover body 2 (see Figure 6 ), the bottle body 1 and the cover body 2 are connected through the external thread 11 and the internal thread 21 that cooperate with each other. To prevent dust, prevent the cosmetics in the bottle body 1 from being polluted, and better protect and preserve them. The dust cover 3 is provided with a strip-shaped liquid storage tank 31, and one end of the liquid storage tank 31 extends downward to form a The liquid inlet 32 of the bottle body 1 communicates with each other, and a one-way valve mechanism 33 is arranged in the liquid inlet 32. The uppe...

Embodiment 2

[0023] The difference between this embodiment and embodiment 1 is: as Figure 4 As shown, the one-way valve mechanism 33 includes a concentric tube 331 arranged at the center of the liquid inlet 32. The concentric tube 331 is connected to the liquid inlet 32 through a number of connecting rods 332 evenly distributed along the circumference. The concentric tube 331 is embedded with The valve body 333 that cooperates with it, the top end of the valve body 333 extends radially to form a limiter 334 that conflicts with the liquid inlet 32, and the bottom end of the valve body 333 extends radially to form a limiter that conflicts with the concentric tube 331. Part two 335, when the end corresponding to the liquid inlet 32 on the pressing part 51 is pressed downward by hand, the limit part one 334 is in conflict with the liquid inlet 32, and then the liquid inlet 32 is closed, and it is placed in the liquid tank 31 The cosmetics move toward the end of the liquid outlet 52. Whe...

Embodiment 3

[0025] The bottle body 1 is made of transparent plastic material. As another embodiment, the bottle body 1 can also be made of other rigid materials such as glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com