Quantitative loading device and quantitative loading method

A sliding device and power device technology, applied in loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of low efficiency of repeated loading, environmental pollution of coke powder, inaccurate loading quantity, etc., and achieve the loading effect Good, the working environment is clean, and the loading effect is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

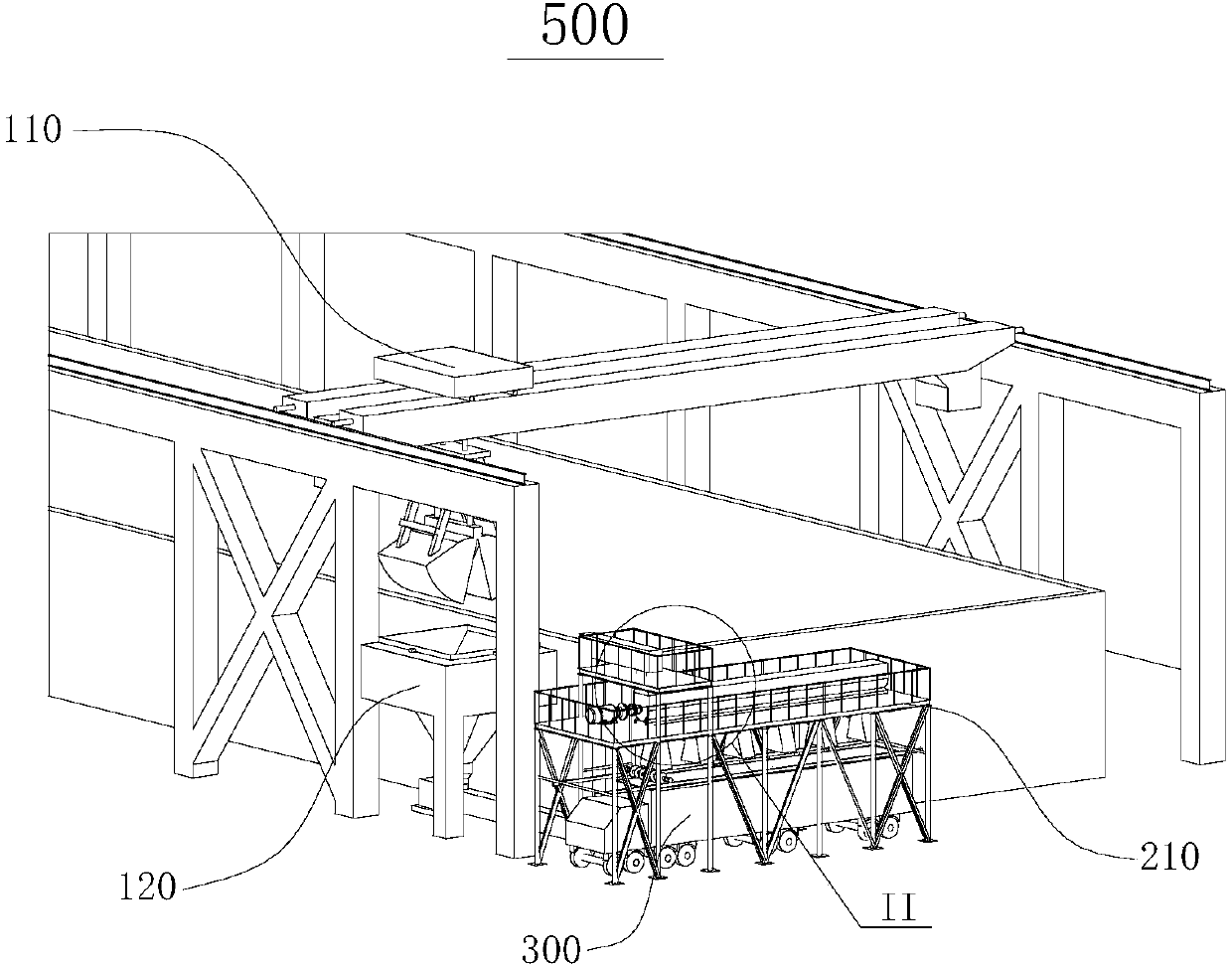

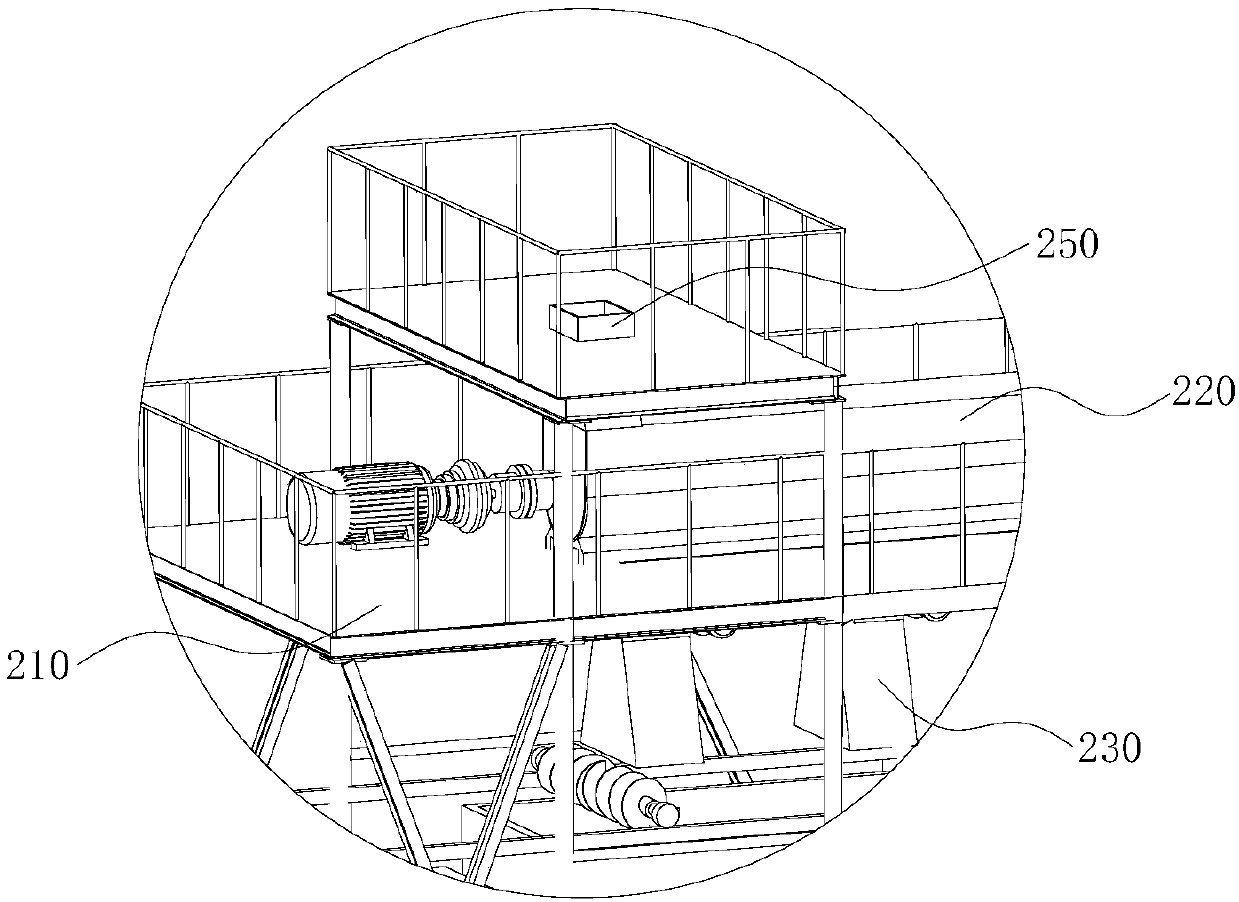

[0055] refer to figure 1 , the figure is a quantitative loading device 500 provided in this embodiment, and refer to figure 2 It includes a material grabbing mechanism 110 , a conveying mechanism 120 , a loading platform 210 , a flat material pipeline 220 and several material outlets 230 . Use the grabbing mechanism 110 to grab the material to the conveying mechanism 120 , and then use the conveying mechanism 120 to transport it to the flat material pipeline 220 on the loading platform 210 , and finally load the material evenly on the conveying equipment through the discharge port 230 . The quantitative loading device 500 has a high degree of automation, a good loading effect and reduces the impact of material drift on the working environment.

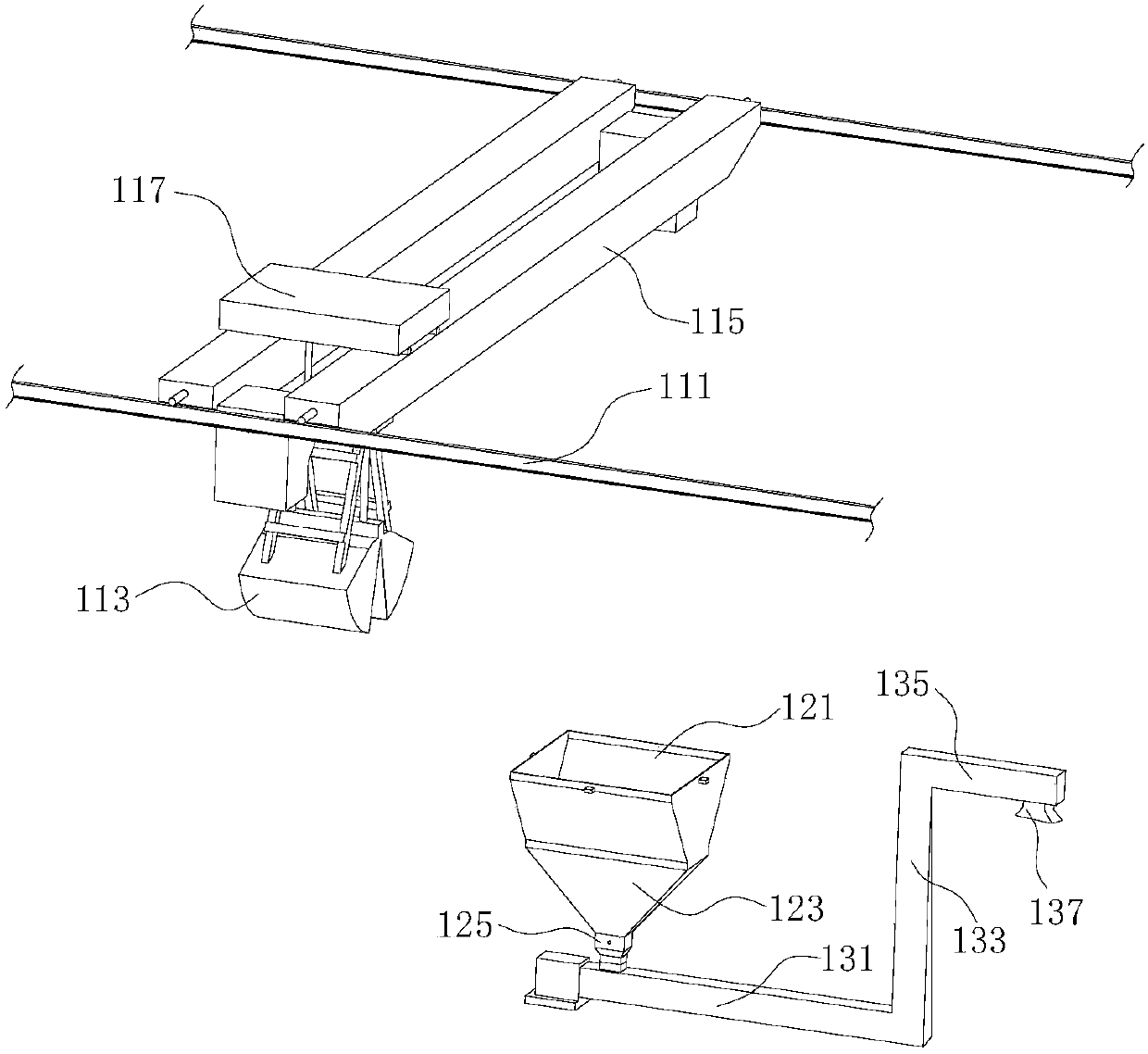

[0056] refer to image 3 , the grasping mechanism 110 includes a first guide rail 111 and a grab hopper 113, and the grab hopper 113 is used to grab raw materials and transport the raw materials to the conveying mechanism 120 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com