Variable thickness full section rock heading machine cutterhead

A full-section, variable-thickness technology, used in mining equipment, earth-moving drilling, tunnels, etc., can solve the problem of poor uniformity of cutter head deformation, and achieve the effects of improving utilization, reducing vibration and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0067] The variable-thickness full-section rock boring machine cutter provided in this embodiment is applied to the full-section rock boring machine.

[0068] In the prior art, dozens or even hundreds of disc-shaped hobs are generally arranged on the TBM cutter head (also known as the full-face rock boring machine cutter head), and the thrust acting on each disc-shaped hob can be as high as 30 tons Left and right, wherein, the thrust acting on each disc-shaped hob is, for example, the force perpendicular to the rock-breaking surface and the tunnel surface. In order to avoid the overturning moment of the cutter head during operation, the disc-shaped hobs are generally evenly arranged on the cutter head, that is, the force on the cutter head can be considered to be axisymmetric.

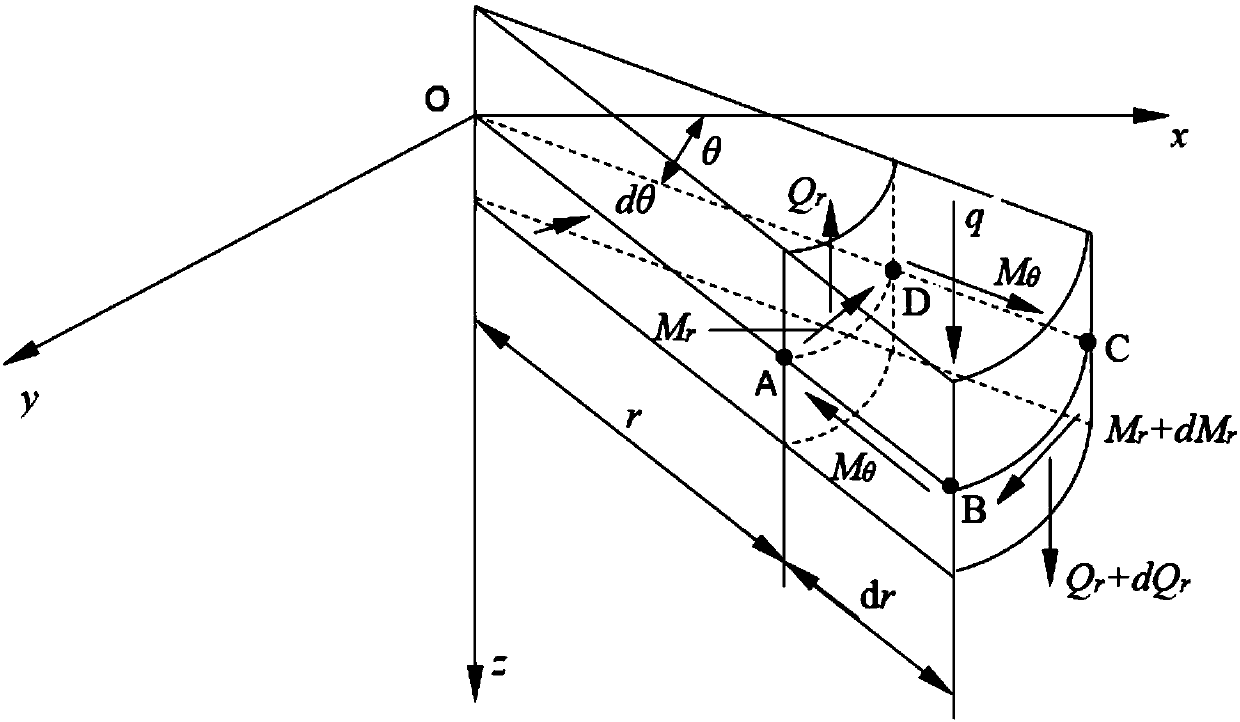

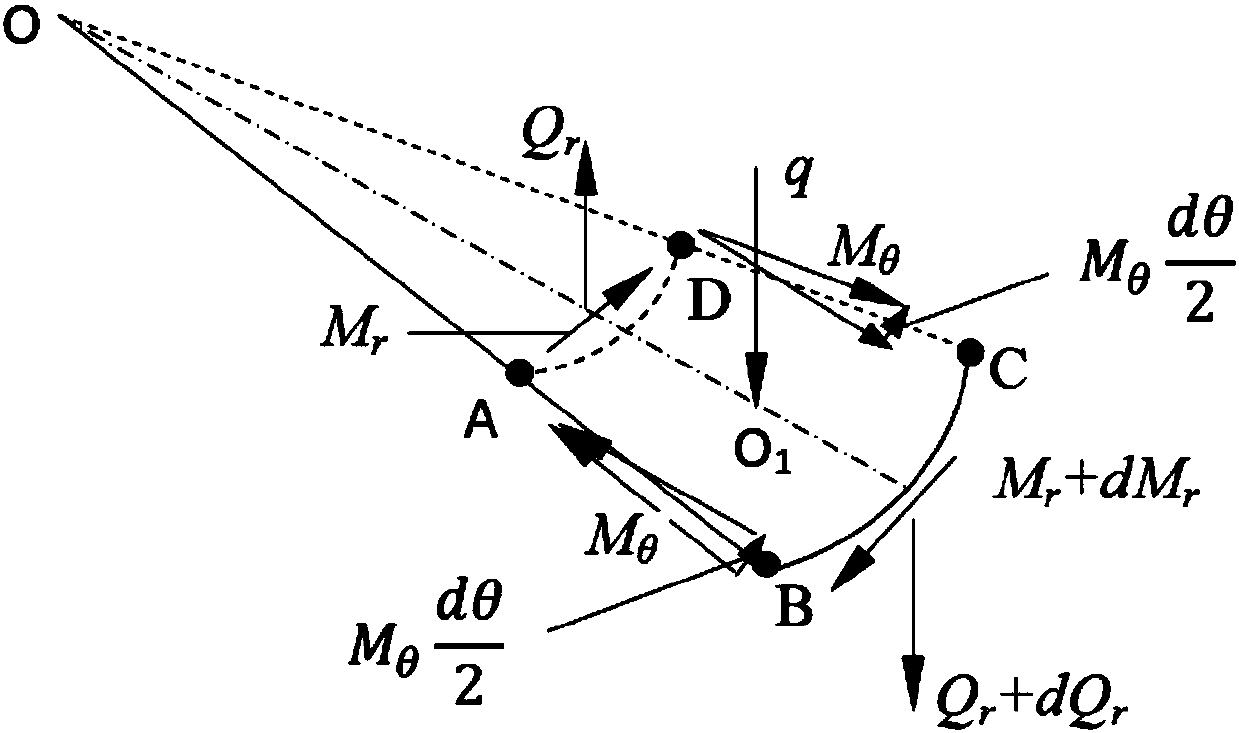

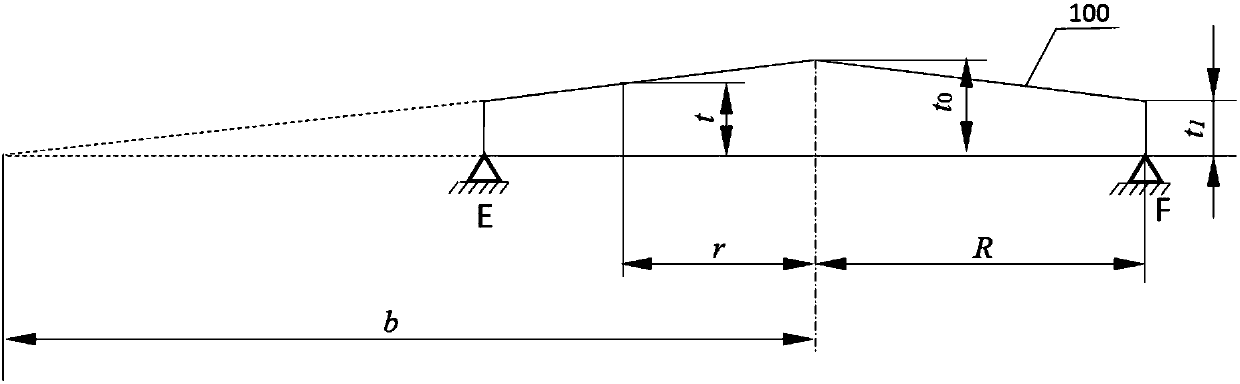

[0069] figure 1 Shown is the TBM cutterhead unit and the forces acting on it, figure 2 shown as figure 1 The unit block of the TBM cutter head unit and the force acting on it, wherein the radial fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com