Bi-directional rapid connection high-performance connection chuck

A quick-connect, high-performance technology, applied in the direction of thin plate connection, connecting components, engine sealing, etc., can solve the problems of single connection method and low connection strength, and achieve the effect of high overall strength, shortened processing cycle, and novel design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

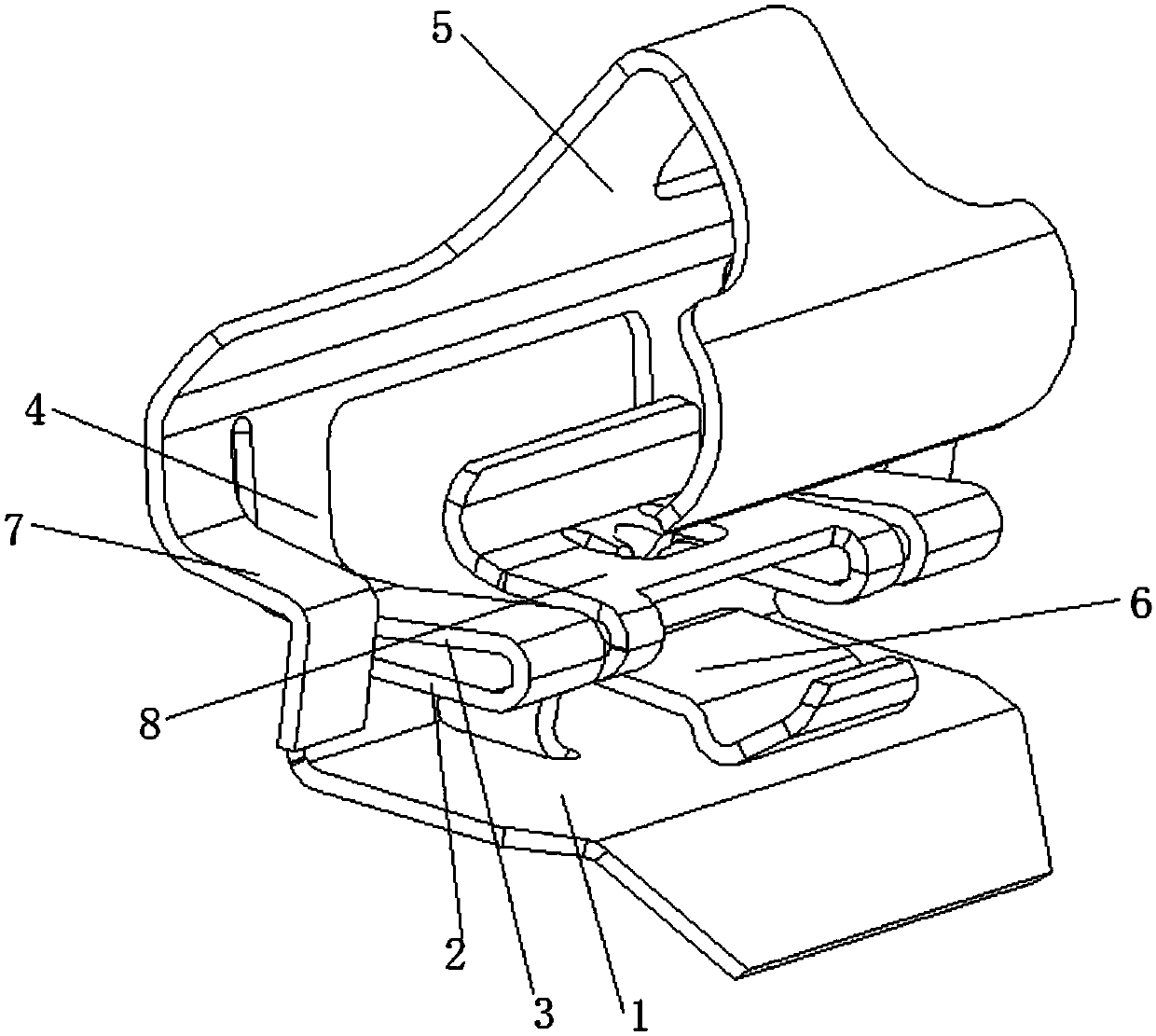

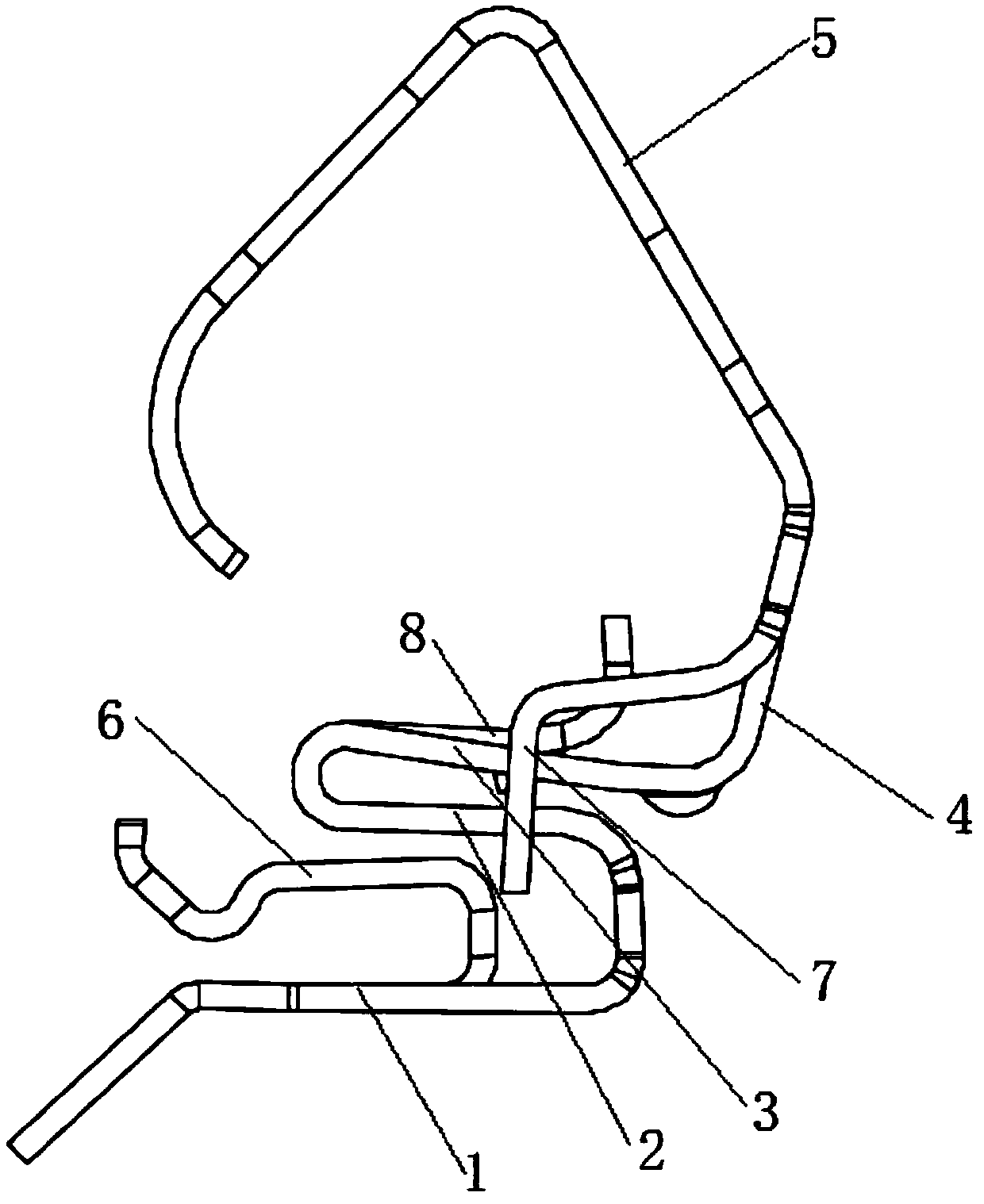

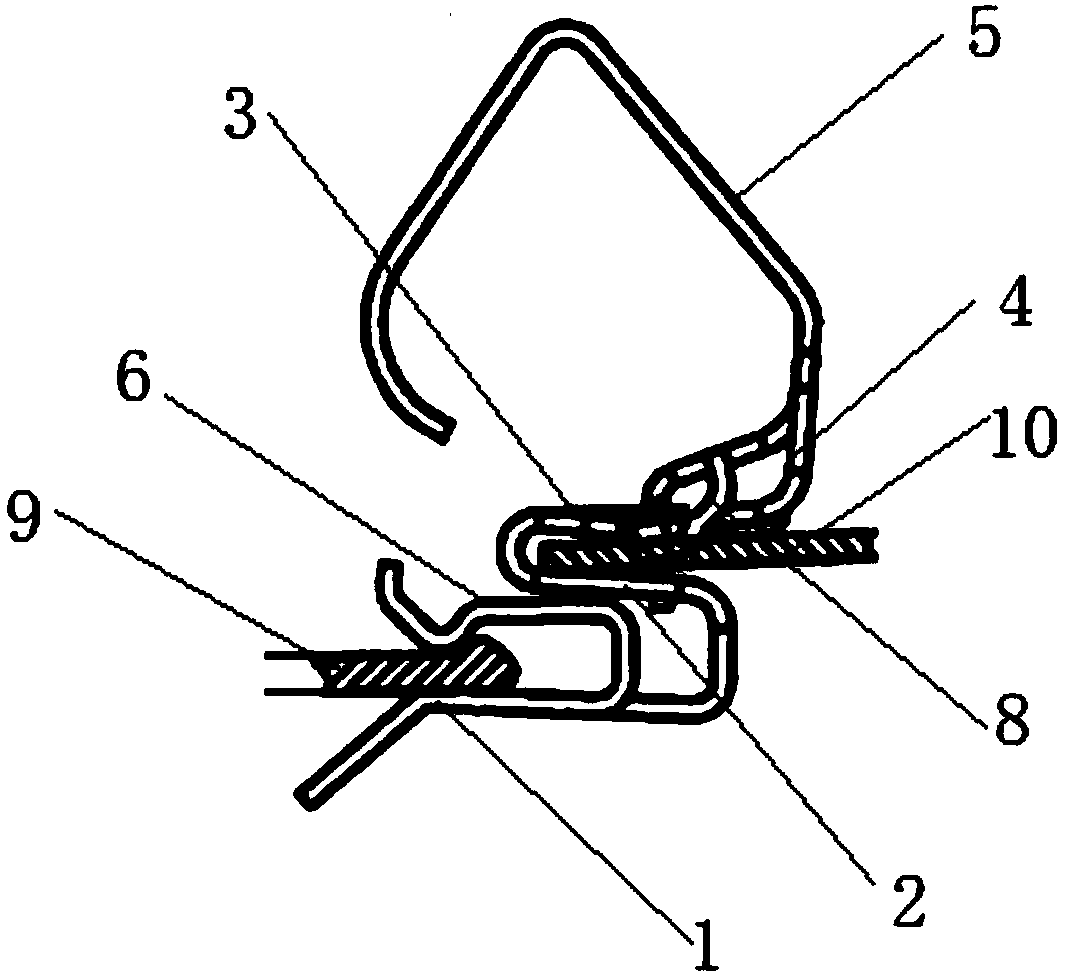

[0026] A two-way quick-connect high-performance connection chuck such as figure 1 , 2 , 3, used for the connection of the T-shaped strip 9 on the car sunroof frame and the sunroof panel 10, the connecting chuck is an integrally formed structure, including the first clamping piece 1, the second clamping piece 2, and the third clamping piece 3. The connecting piece 4 and the elastic hand-held piece 5, the first clamping piece 1, the second clamping piece 2, and the third clamping piece 3 are arranged in parallel, and connected in order to form an S-shaped structure. The first clamping piece 1 A part of the sheet in the middle is bent back to form the fourth clamping piece 6, and the first clamping groove for clamping the T-shaped strip on the car sunroof frame is formed between the fourth clamping piece 6 and the first clamping piece 1, and the second clamping groove is formed between the fourth clamping piece 6 and the first clamping piece 1. Before the clamping piece 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com