Spiral water cooling wall structure of steam-injection boiler

A steam injection boiler and water-cooled wall technology, which is applied to steam boiler components, steam boilers, steam boiler accessories, etc., can solve the problems such as the spiral water-cooled wall structure of steam injection boilers, so as to improve the service life and ensure safe operation , the effect of reducing installation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

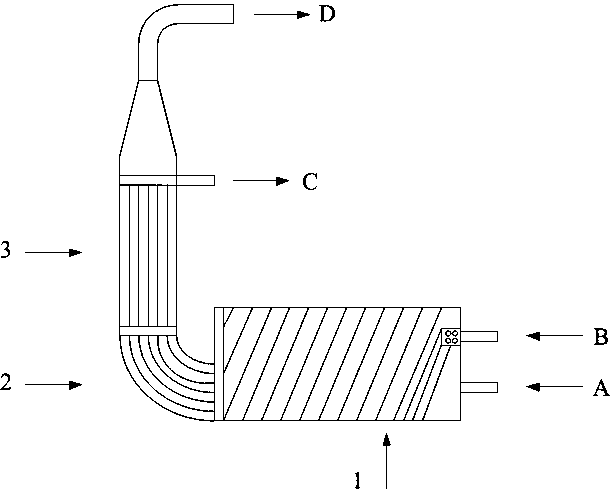

[0013] combine figure 1 It can be seen that the embodiment of the present invention is: the spiral section of the water cooling wall is installed at the right end of the curved section of the water cooling wall, and the vertical section of the water cooling wall is installed at the upper end of the curved section of the water cooling wall; the curved section of the water cooling wall adopts a telescopic hose; the water cooling wall Each section is directly connected with a water tank.

[0014] The core idea of the embodiment of the present invention is: by adopting the spiral water wall structure in the horizontal section of the steam injection boiler, the strain resistance of the water wall tube bundle due to changing working conditions is improved, and the water flow resistance at the elbow is reduced; The horizontal and vertical sections of the steam injection boiler adopt stretchable and curved metal hoses to reduce the impact of boiler shaking and reduce the installatio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap