Wire harness assembly size and staple bolt examining and testing device and testing method thereof

A wire harness assembly and testing equipment technology, applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of inability to install accessories, too long wire harness size, excessive noise, etc., to achieve high accuracy, improve product quality, Apply convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

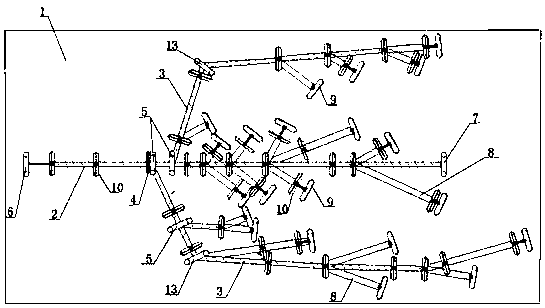

[0029] The following is attached figure 1 An embodiment of the invention is described:

[0030] The wire harness assembly size and staple inspection and testing equipment includes an inspection board 1;

[0031] The corresponding wiring harness structure on the inspection board 1 is provided with: main line aisle 2, first-level branch aisle 3, reference point 4, branch line positioning support 5, front positioning support 6, and rear positioning support 7;

[0032] The main line aisle 2 is a straight line, and its length is consistent with the length of the main line of the wiring harness; the front end of the main line aisle 2 is provided with a front positioning support 6, and the rear end of the main line aisle 2 is provided with a rear positioning support 7;

[0033] The main line aisle 2 is provided with branch line positioning supports 5 at each branch point corresponding to the wiring harness. The end extends obliquely backward; the first-level branch aisle 3 is cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com