CCD-based linearity test method of swinging mirror

A test method and linearity technology, which are applied to measuring devices, instruments, optical devices, etc., can solve the problems of limited scale accuracy, inconvenient testing, limited accuracy, etc. Imaging effect optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

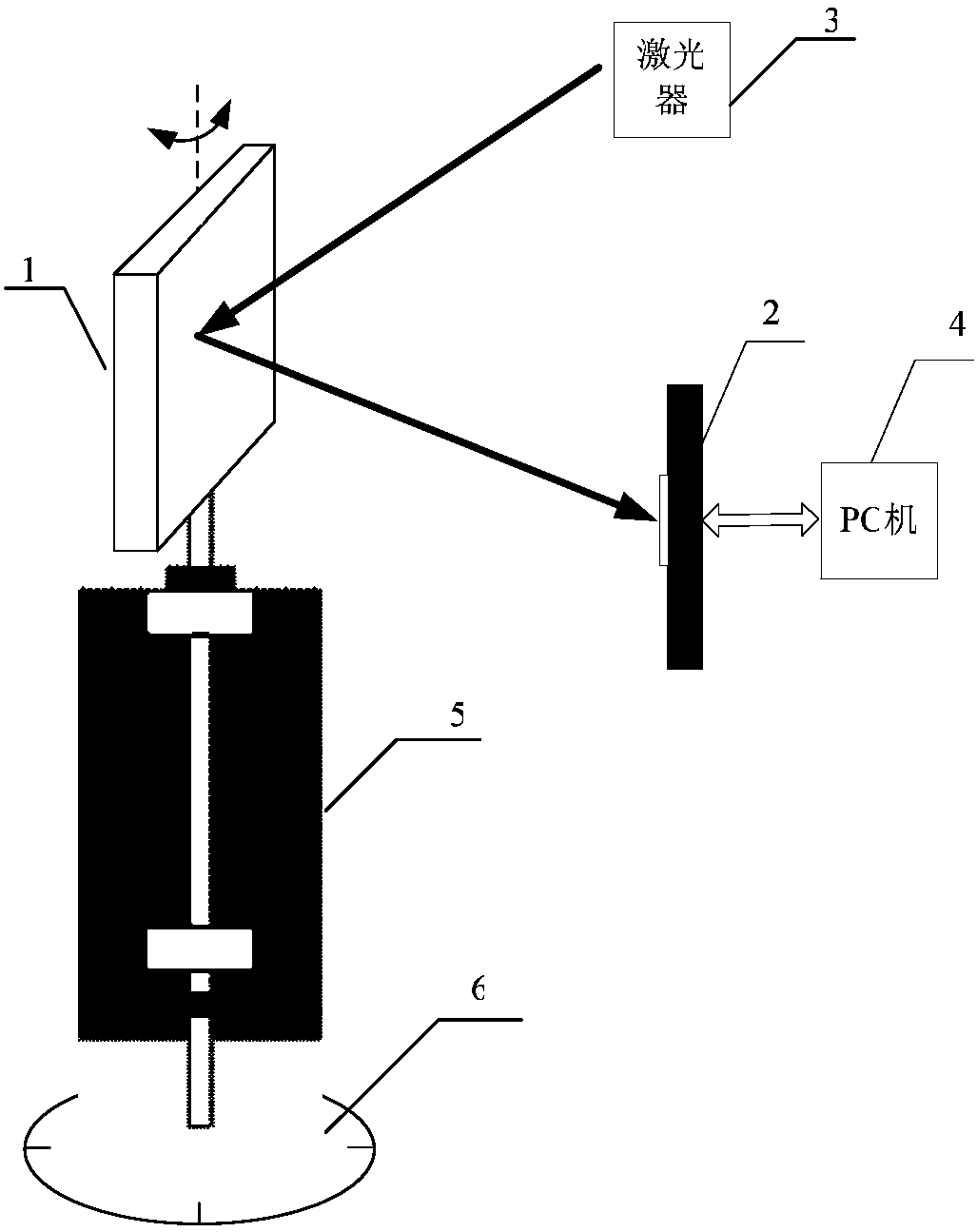

[0012] Such as figure 1 As shown, the equipment used in the CCD-based pendulum mirror linearity test method mainly includes pendulum mirror 1, linear image sensor (CCD) 2, laser 3, and PC 4. The swing mirror 1 is connected to one end of the output shaft of the motor 5, and the other end of the output shaft of the motor 5 is connected to a high-precision photoelectric encoder 6. The pendulum mirror is driven to rotate by a motor, and a laser light source is used to illuminate the pendulum mirror, and a CCD is used to receive the reflected light of the pendulum mirror.

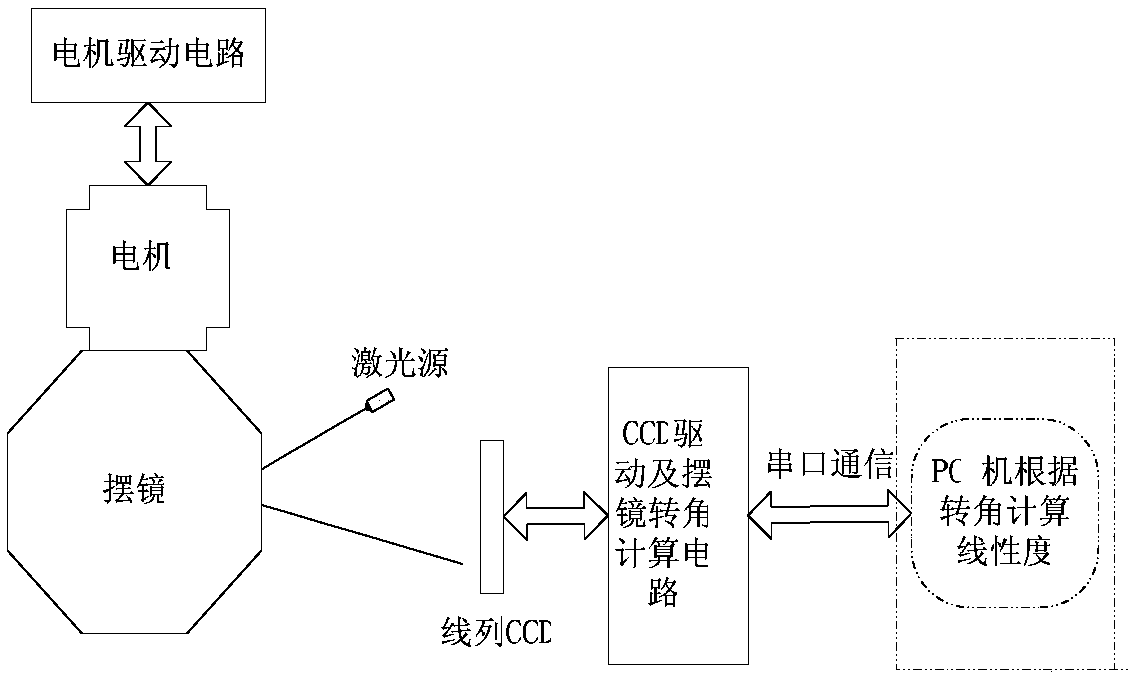

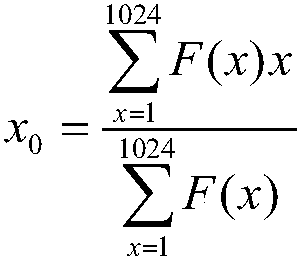

[0013] Such as figure 2 As shown, the CCD is used to receive the reflected light of the swing mirror to obtain a series of spot signals. The CCD converts the collected spot signals into analog electrical signals, and after AD conversion, they are output to the CCD drive circuit for calculations to calculate the coordinates of each spot Information; at the same time, the CCD reads the angle information of the swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com