Method for measuring whole-process autogenous volume deformation of concrete

A volume deformation, concrete technology, applied in measuring devices, using stable tension/pressure testing materials strength, instruments, etc., can solve the problem of difficult to reflect the actual situation of the project, affecting the decision-making of project builders, and concrete can only be used at constant temperature and absolute temperature. Problems such as the constant temperature room under humid conditions, to achieve the effect of improving the limitations and deficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following examples illustrate possible implementations of the present invention, but they are not intended to limit the protection scope of the present invention and are described in advance.

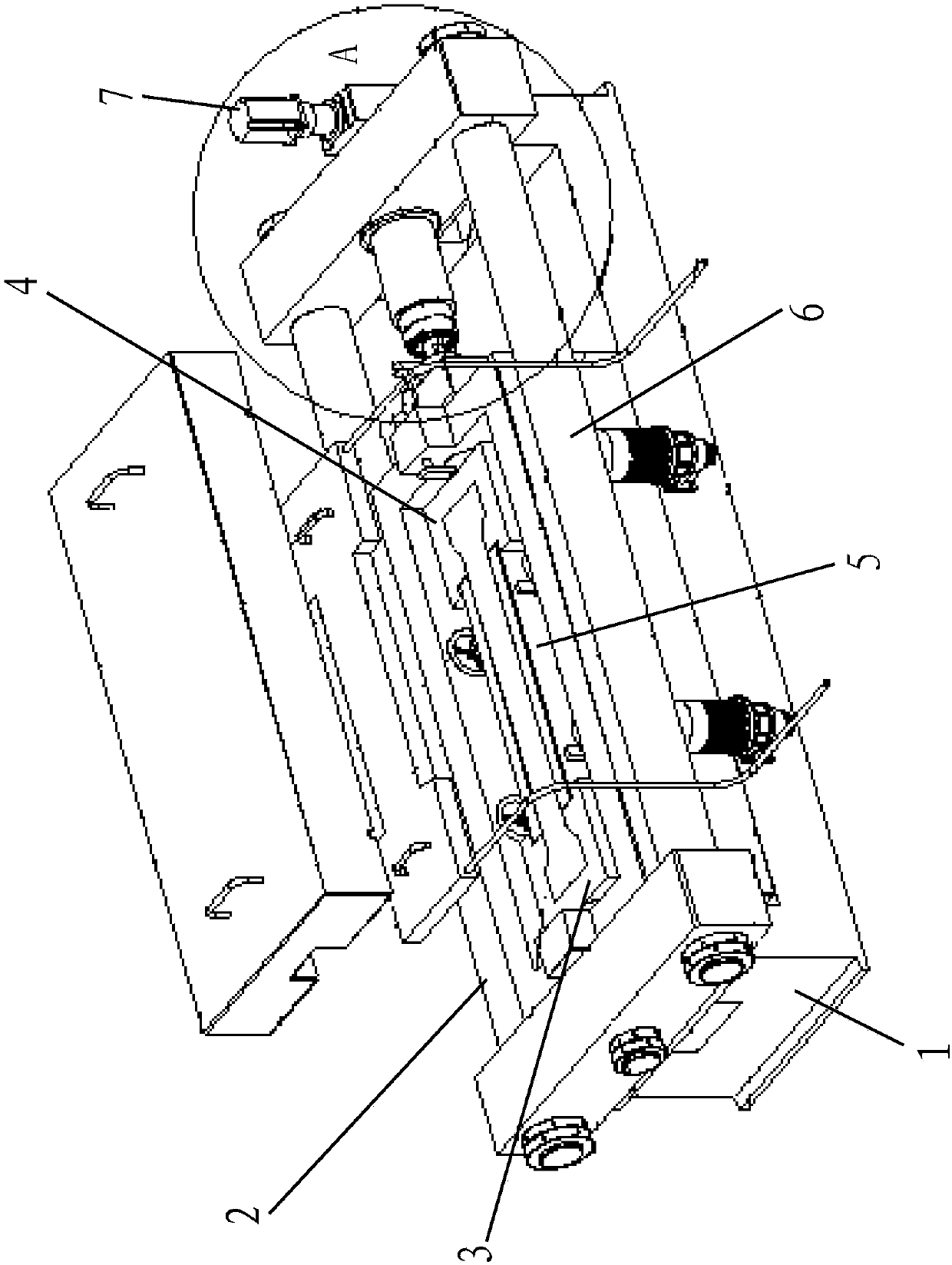

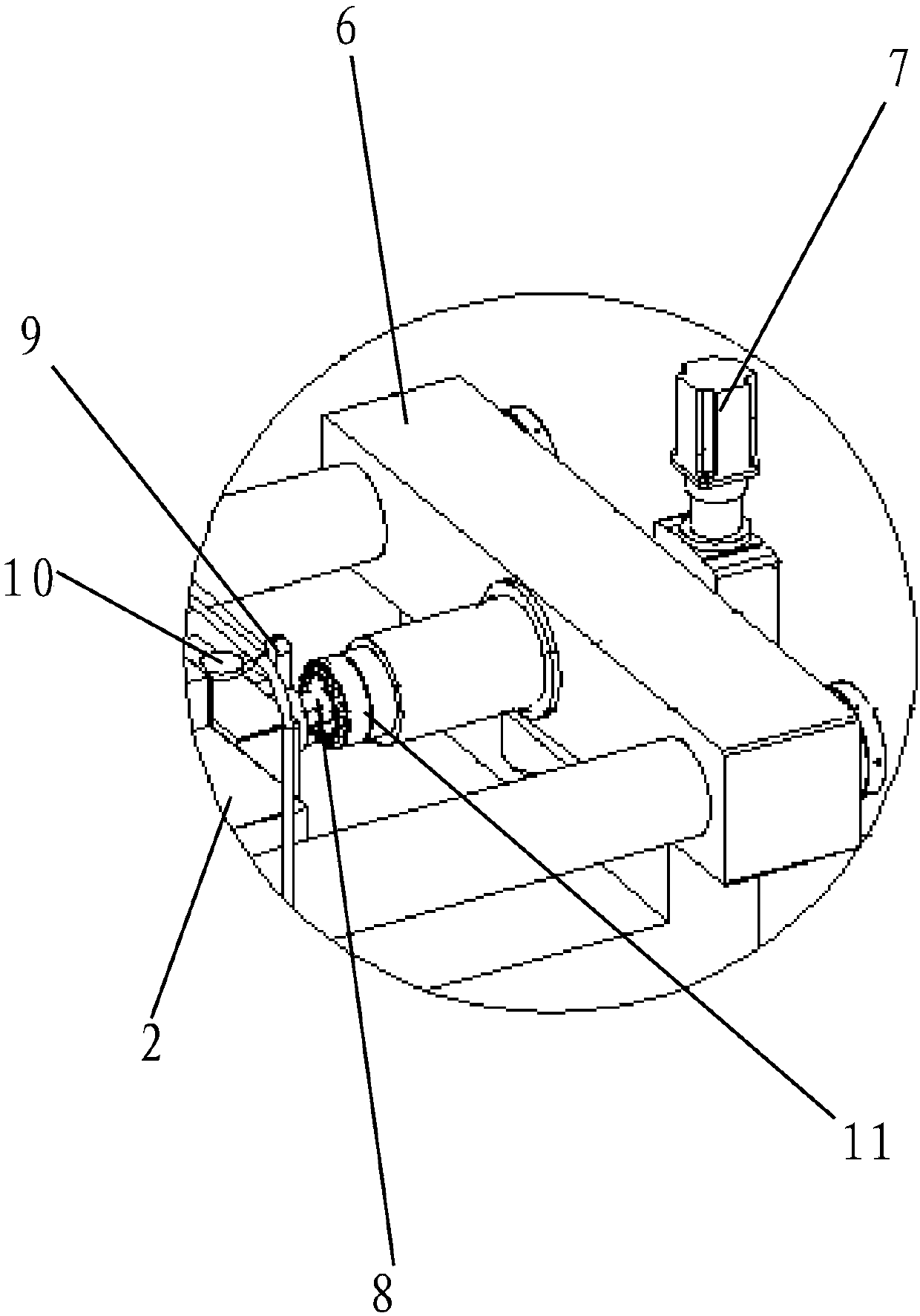

[0048] Such as figure 1 , figure 2 As shown, the present invention provides a method for measuring the autogenous volume deformation in the whole process of concrete, which utilizes a test device, which includes a base 1, and an environmental chamber 2 for isolating the external environment is arranged on the base 1, the environment The box 2 is provided with a concrete specimen accommodation device.

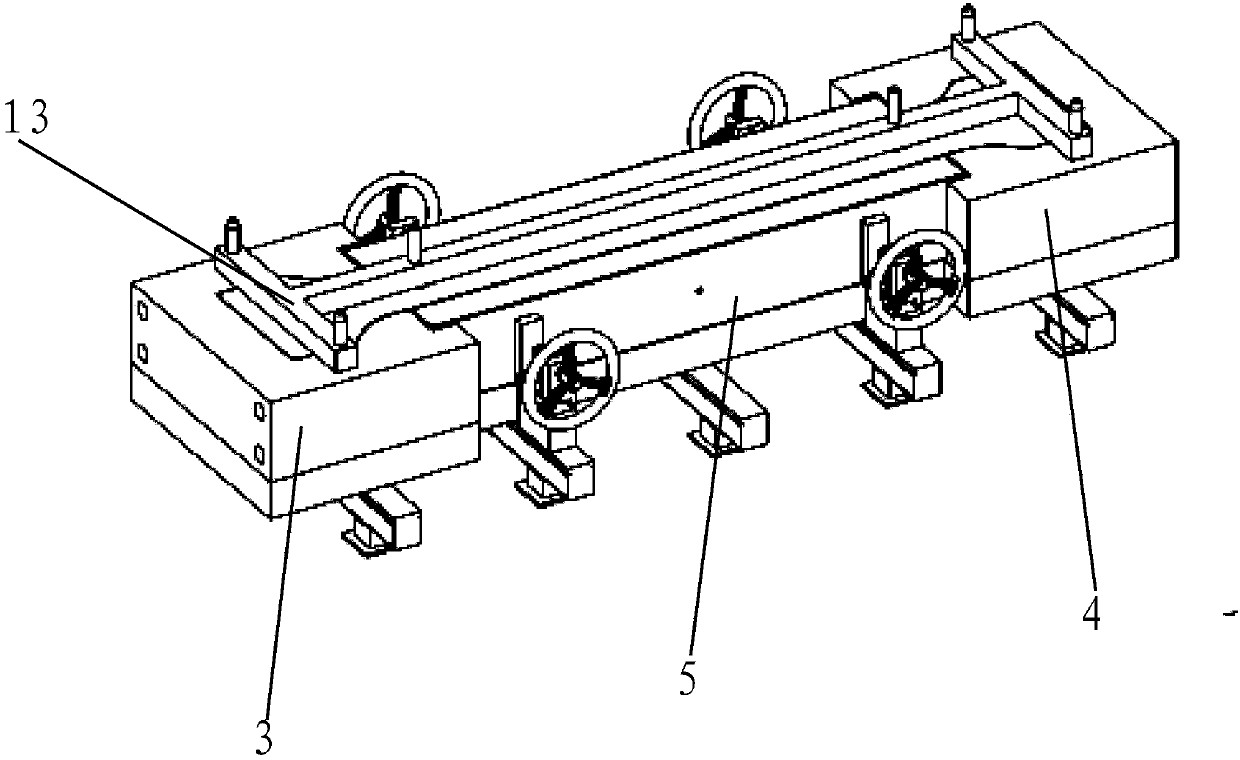

[0049] The concrete specimen accommodating device includes a fixed chuck 3, a movable chuck 4, and two side formworks 5, which are combined to form an accommodating space with an open upper end or an open upper and lower end. The fixed chuck 3 is fixedly arranged on the At one end of the environmental chamber 2, the movable chuck 4 is arranged on the other end of the environ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap