Auxiliary assembling apparatus for enabling end parts of two wires to extend to dual-channel terminal

A dual-channel, auxiliary group technology, applied in the assembly/disassembly of contacts, can solve the problems of time-consuming and laborious, limited personnel operation fatigue, affecting the company's production efficiency, etc., achieving good auxiliary, outstanding substantive features, Good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The features of the present invention and other relevant features are described in further detail below through the embodiments, so as to facilitate the understanding of those skilled in the art:

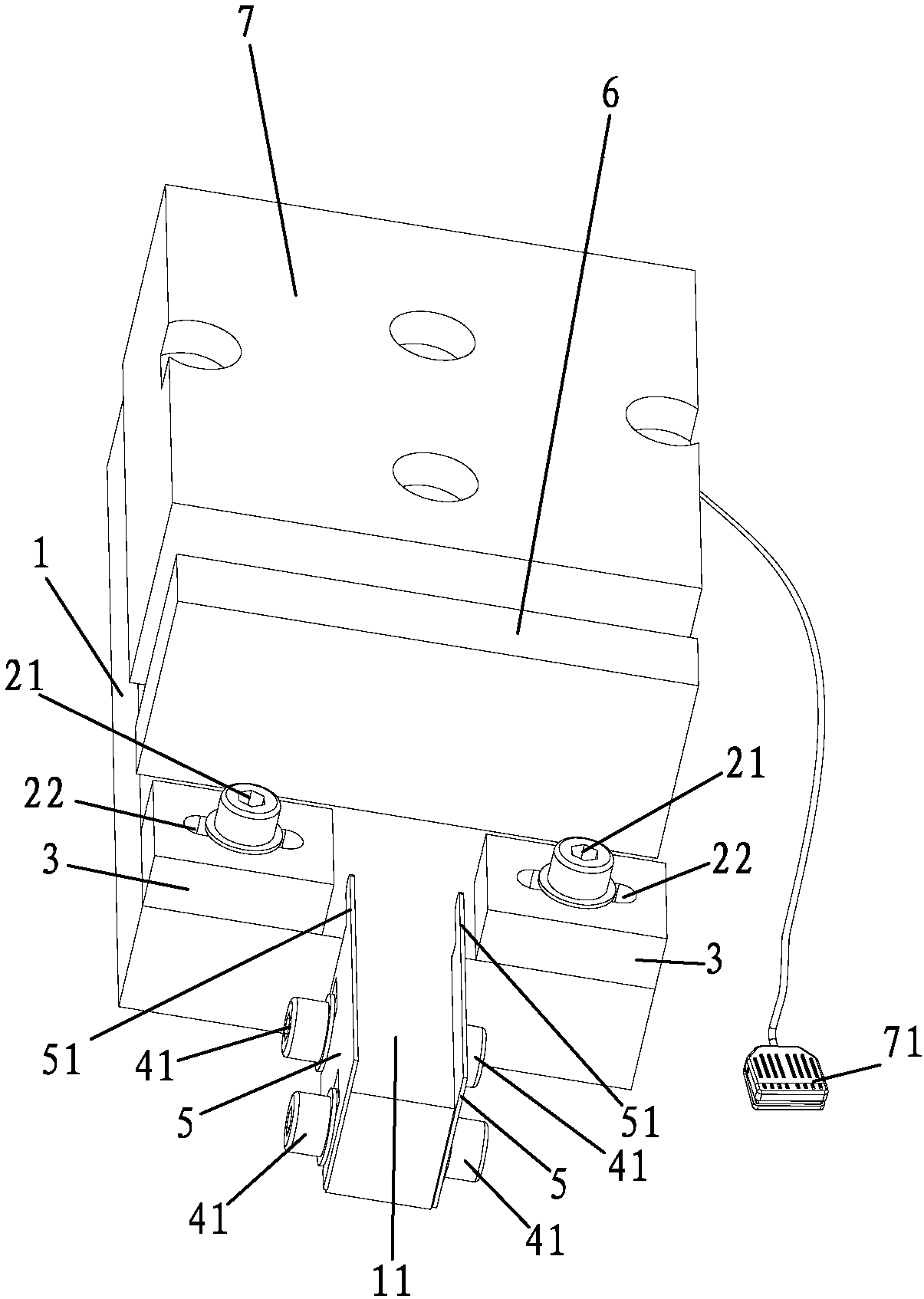

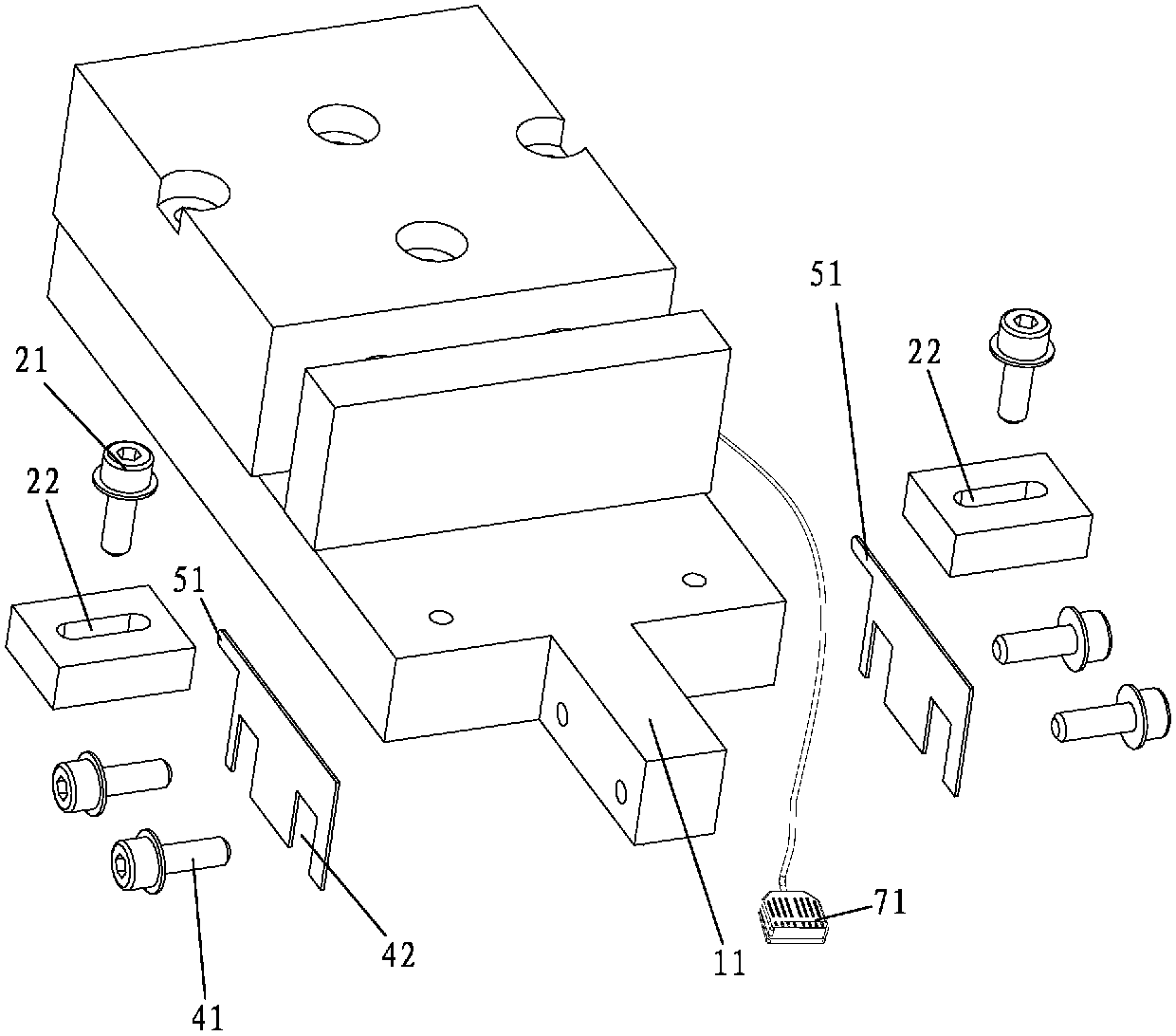

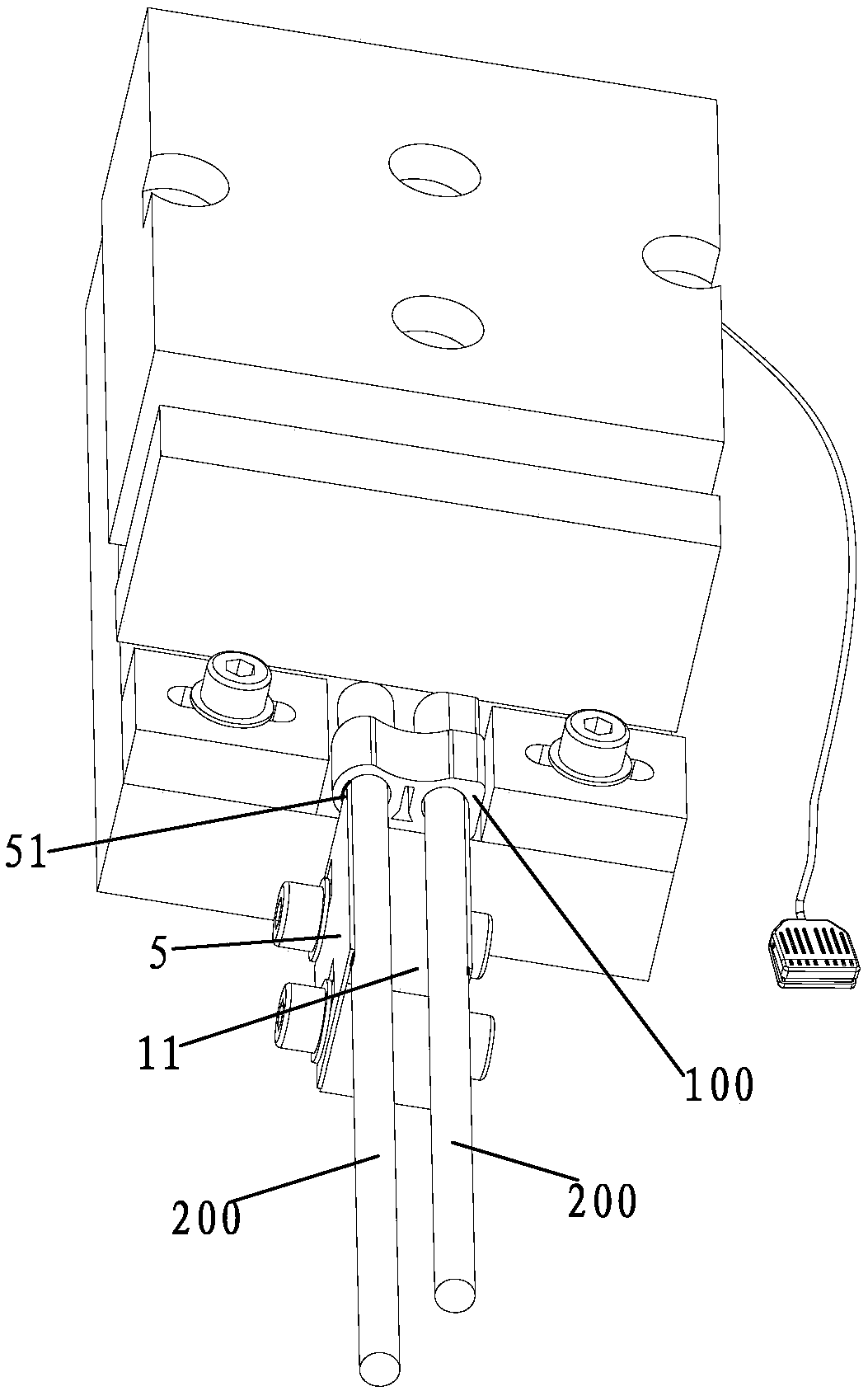

[0018] Such as Figure 1-Figure 3 As shown, an auxiliary assembly device for making the ends of two wires go deep into the dual-channel terminal includes a bottom plate 1 on which vertical screws 21 are respectively installed to move the double-channel terminal 100 left and right. The left and right terminal side limiter 3 of the side limit, the front end of the bottom plate 1 is provided with a protruding part 11 for supporting the wire 200, and the left and right side walls of the protruding part 11 are respectively passed through transverse screws 41 A terminal front-end limiter 5 for limiting the front end of the dual-channel terminal 100 is installed, and the terminal side limiter 3 is provided with a first left-right stroke for the vertical screw 21 to be installed ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com