Laser driven microwave pulse emitting device

A pulse emission and laser-driven technology, applied in the field of microwave radiation, can solve the problems of transient output power limitation, high maintenance cost, complex structure, etc., and achieve the effect of easy miniaturization, convenient maintenance, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

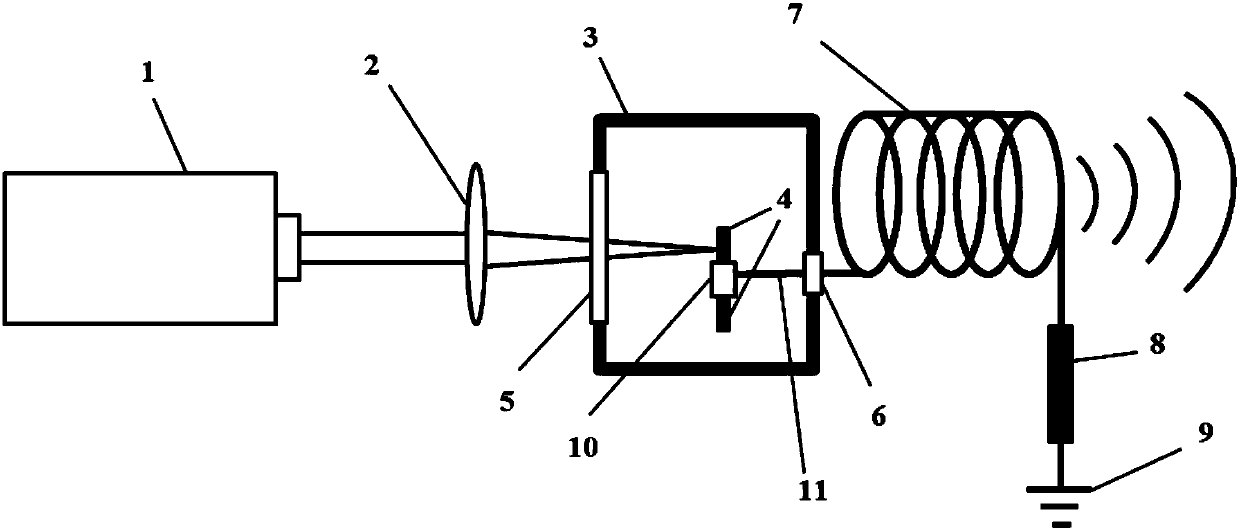

[0018] This embodiment provides a laser-driven microwave pulse emission device, see the attached figure 1 , including: pulse laser 1, focusing lens 2, vacuum cavity 3, metal sheet 4, glass window 5, vacuum electrical connection plug 6, metal coil 7, matching resistor 8, rotating shaft 10 and wire 11;

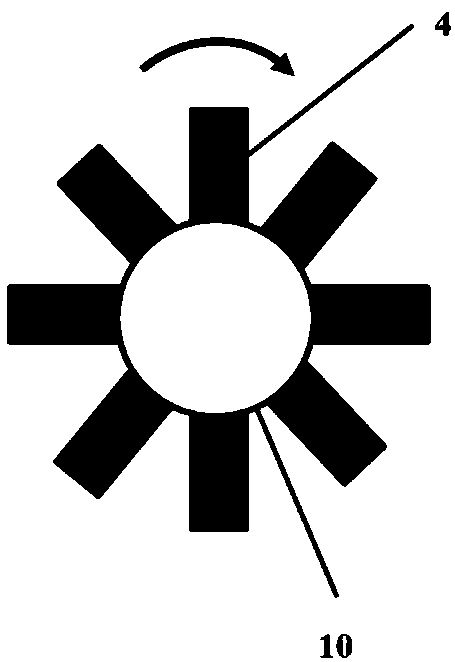

[0019] More than two metal sheets 4 are fixed on the rotating shaft 10 along the circumferential direction; the rotating shaft 10 is fixed in the vacuum chamber 3, and the rotating shaft 10 can rotate around its axis under the action of the motor; the rotating shaft 10 is fixed in the vacuum chamber through the wire 11 One end of the vacuum electrical connection plug 6 on the side of the body 3 is electrically connected, and the other end of the vacuum electrical connection plug 6 is electrically connected to one end of the metal coil 7 located outside the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com