Bus motor assembly

A bus and assembly technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of parts damage, limit the range of use of motors, affect the stability and service life of motors, etc., to improve heat dissipation performance and improve heat dissipation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

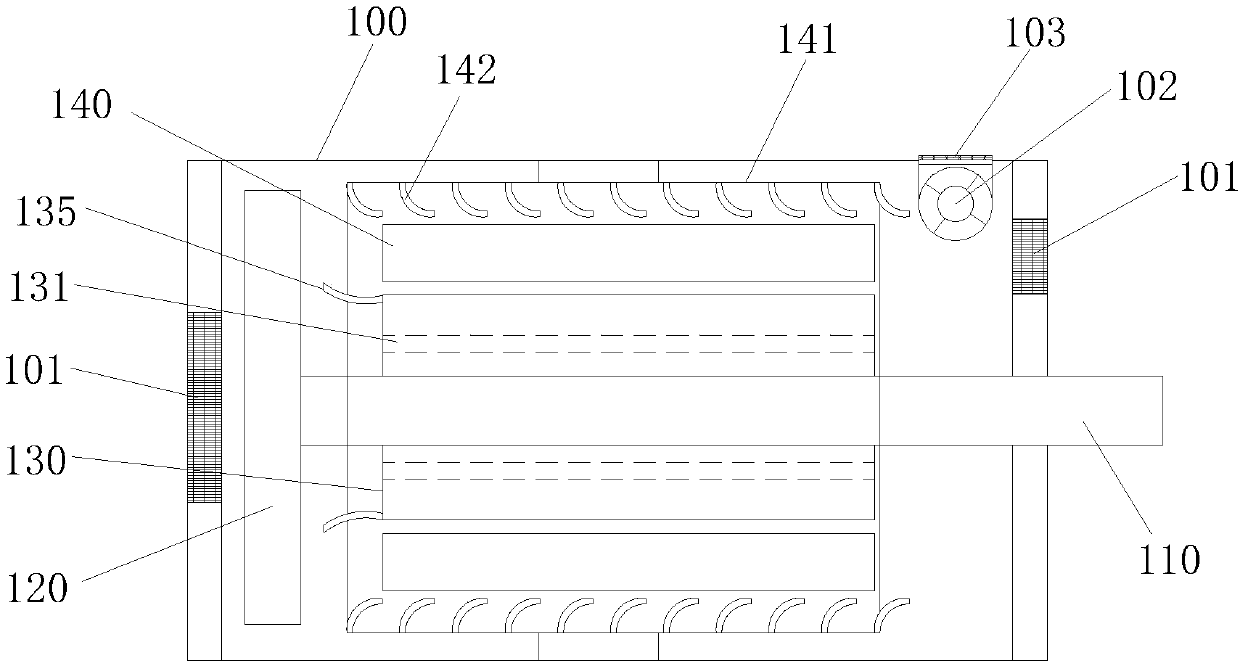

[0020] Such as figure 1 As shown, a bus motor assembly includes a casing 100, the casing 100 is provided with a rotating shaft 110, a rotor 130 sleeved and fixed on the rotating shaft 110, and a stator 140 cooperating with the rotor 130 to rotate , one end of the rotating shaft 110 passes through the casing 100 , and the other end of the rotating shaft 110 is provided with a fan 120 .

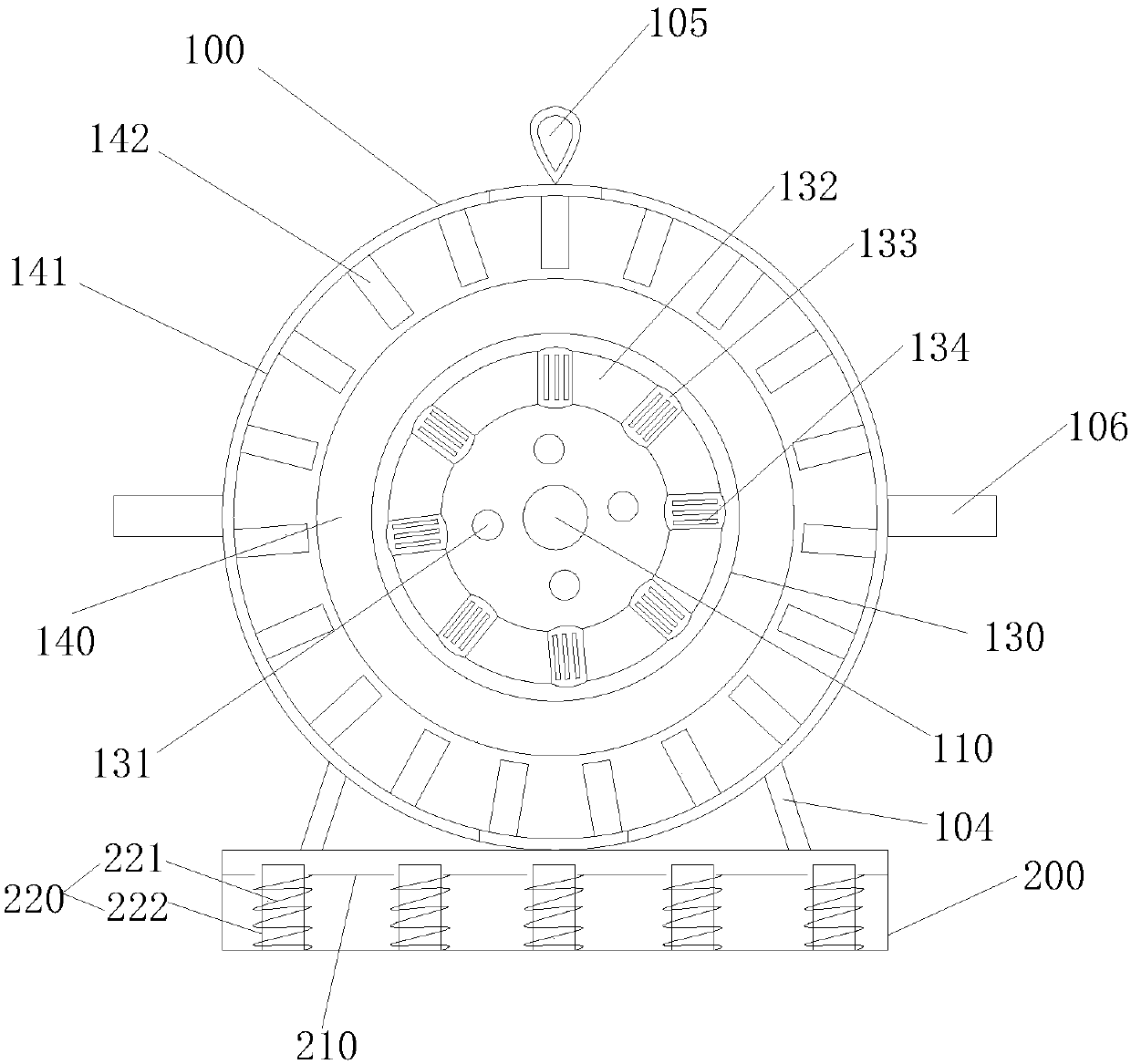

[0021] Such as figure 2 As shown, the rotor 130 is provided with a plurality of cooling passages 131 along the length direction of the rotating shaft 110. The cooling passages 131 are arranged around the rotating shaft 110 and run through the rotor 130. The surface of the rotor 130 is along the A plurality of installation slots 132 are evenly spaced along the length direction of the rotating shaft 110, and permane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com