Unpowered ore separator

A technology of ore separator and power, applied in the field of mining machinery and equipment, can solve the problems of high processing and manufacturing costs, uneven ore separation, high energy consumption, etc., and achieve the effects of low processing and production costs, uniform ore separation, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

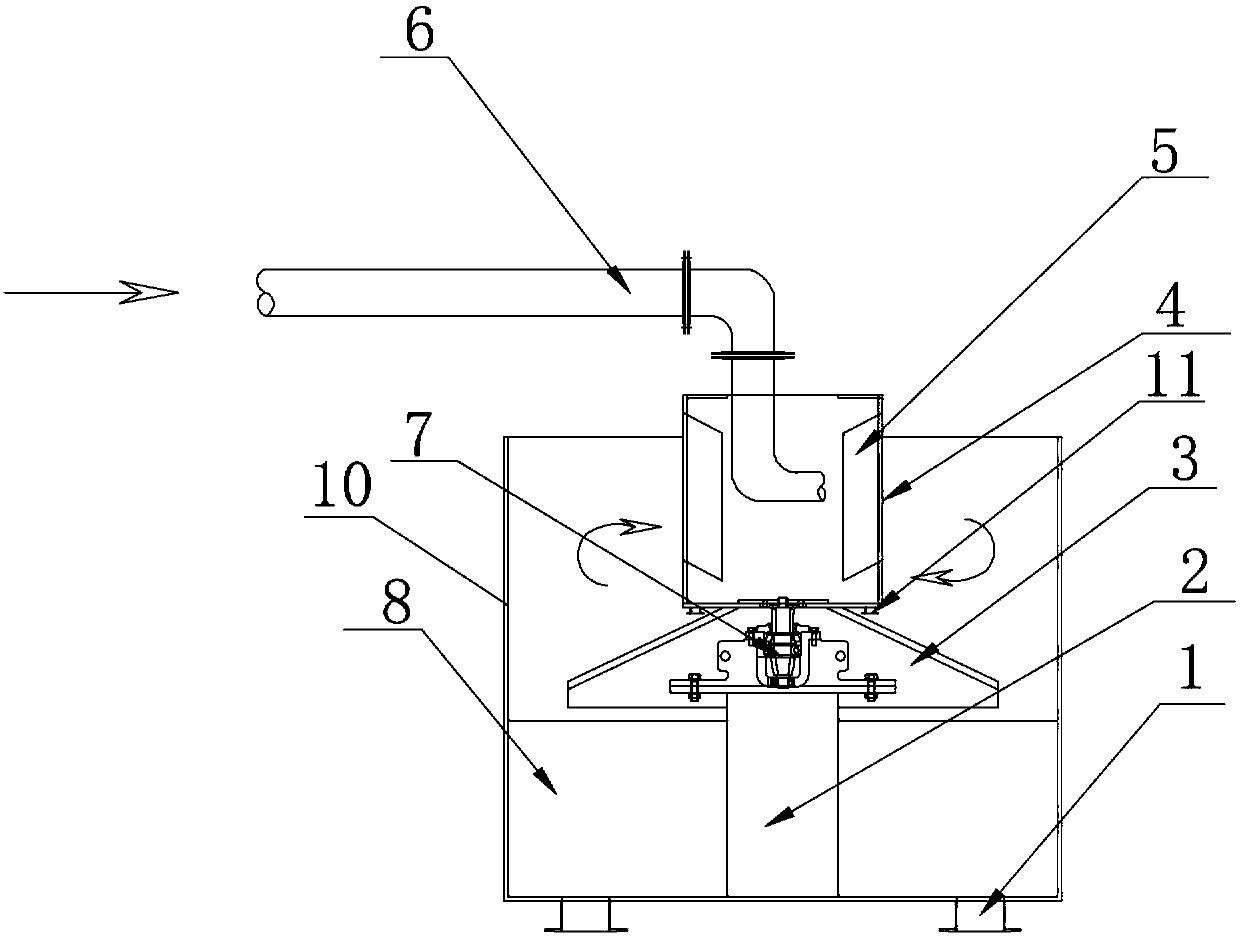

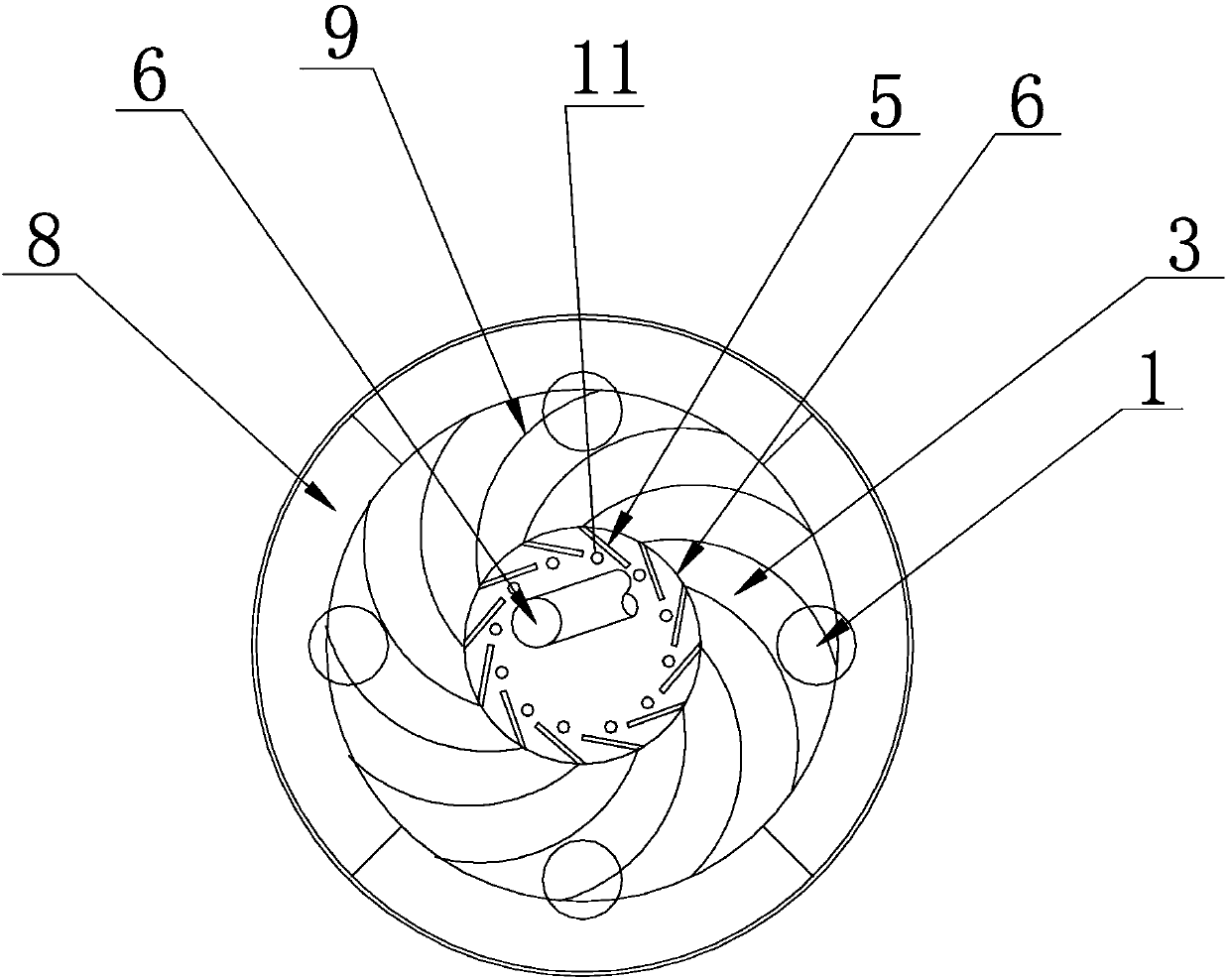

[0040] The non-powered ore separator described in this embodiment is used for gravity feeding equipment, see figure 1 , figure 2 , a structural schematic diagram of a non-powered ore separator, a top view structural diagram of a non-powered ore separator, a non-powered ore separator, including an ore separation pipe 1, a transmission device base 2, and a conical ore separator 3 , power bucket 4, blade 5, pulp pipe 6, transmission device 7, ore-connecting tank 8, ore-splitting bar 9, body 10, artesian outlet 11, the inside of the body 10 is provided with a transmission device base 2, and the transmission device The upper part of the base 2 is provided with a transmission device 7, the upper part of the transmission device 7 is provided with a power bucket 4, the inner wall of the power bucket 4 is provided with blades 5, the top of the power bucket 4 is provided with a slurry pipe 6, and the power bucket 4 The bottom is provided with a cone-shaped ore separator 3, which is fi...

Embodiment 2

[0053] The unpowered ore separator described in this embodiment is used for flotation equipment feeding, see figure 1 , figure 2 , a structural schematic diagram of a non-powered ore separator, a top view structural diagram of a non-powered ore separator, including an ore separation pipe 1, a transmission base 2, a conical separator 3, a power barrel 4, blades 5, Ore slurry pipe 6, transmission device 7, ore-connecting tank 8, ore-distributing bar 9, body 10, artesian outlet 11.

[0054] Compared with Embodiment 1, for the description of the structure of the non-powered ore separator in this embodiment, the similarities will not be repeated.

[0055] The use occasions 4-5 described below are supplementary descriptions of the second embodiment.

[0056] Use occasion 4: 3-stage parallel lead concentration flotation machine feeding ore

[0057] Technical index requirements: the distribution volume of a single mine separator is 1.8t / h, and the concentration of ore quality is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com