Rotational joint mechanical arm gravity compensation mechanism

A technology of rotating joints and gravity compensation, applied in the directions of manipulators, manufacturing tools, joints, etc., can solve the problems of inability to achieve accurate sine law changes, the compensation range is not very large, and the control algorithm is complex, so as to solve the problem of limited rotation angle range and avoidance. Structural interference, smooth and reliable motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

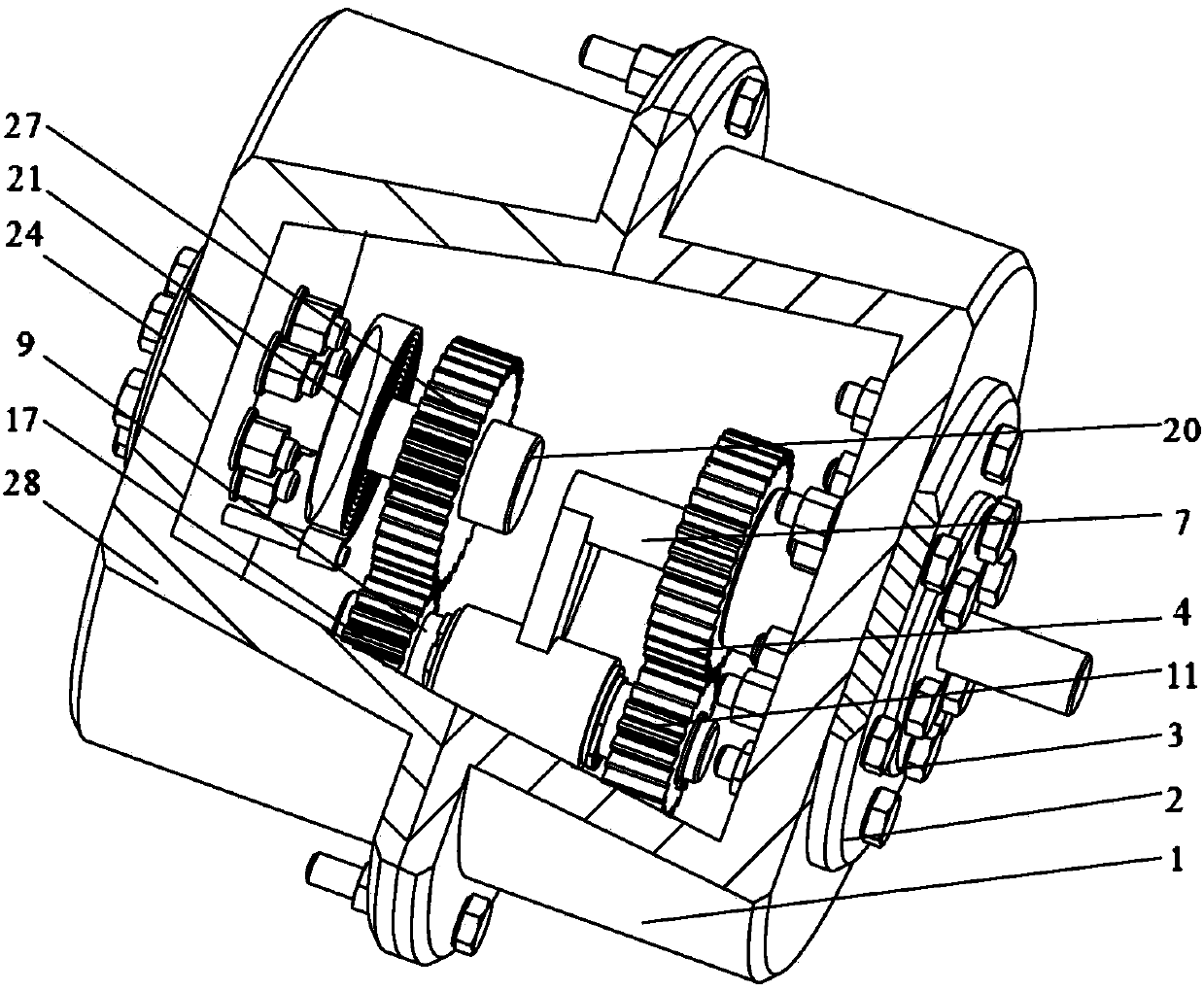

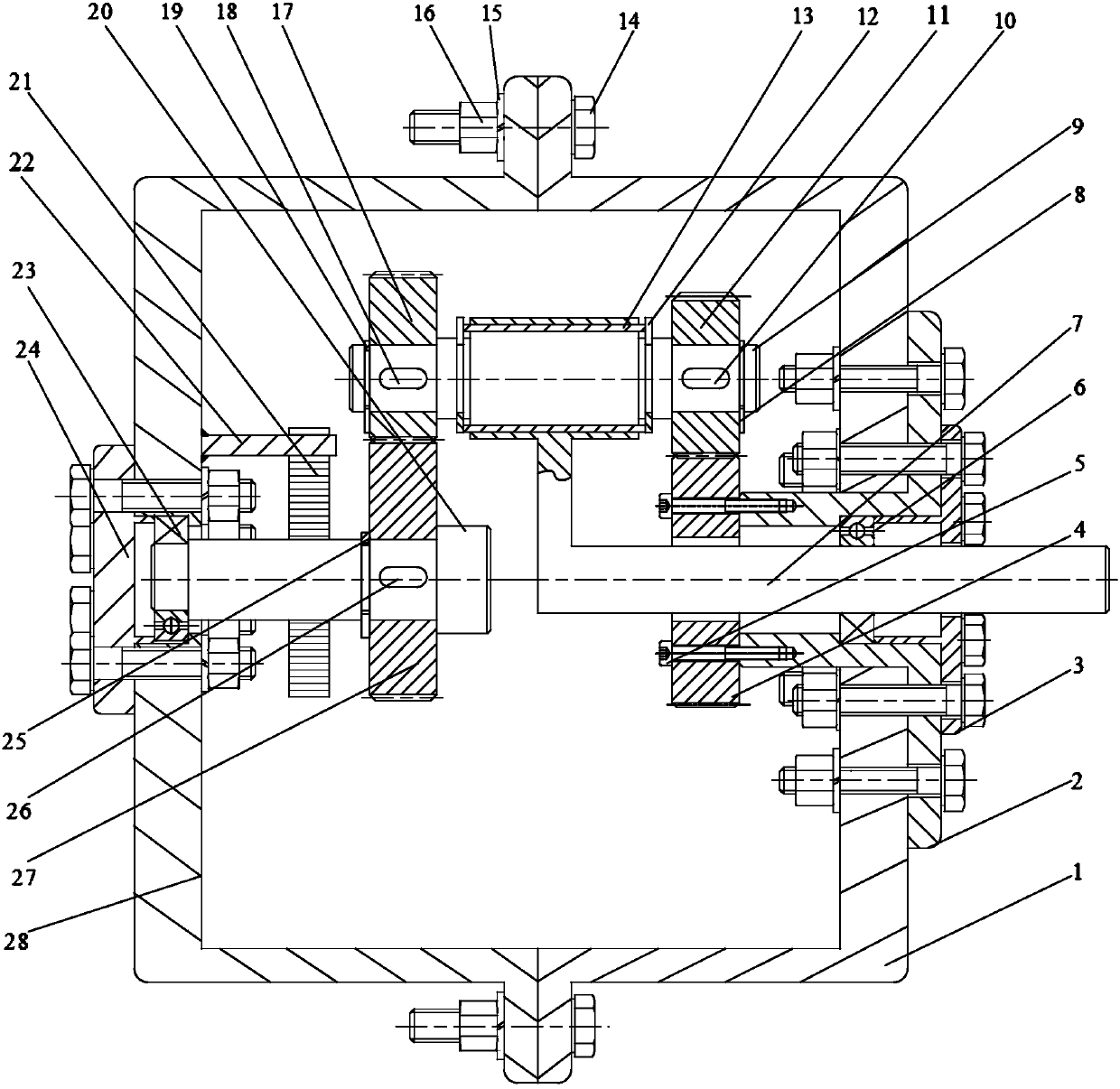

[0027] Example 1: Gravity Compensation for the Parallel Four 2R Manipulator

[0028] Such as Figure 6A As shown, the 2R mechanical arm includes: 33 large arms, 32 small arms, 29 links A, 30 links B, and 31 links C of the four-bar mechanism.

[0029] One end of the robot arm 33 can rotate around a rotation axis L, and the rotation axis L is parallel to the ground F. As shown in FIG. One end of the small arm 32 is disposed on the front end of the large arm 33 , and the small arm 32 can rotate around the rotation axis U, and the rotation axis U is parallel to the rotation axis L. As shown in FIG. The connecting rod A and connecting rod C of the four-bar mechanism are always parallel to the small arm 32 , and the connecting rod B is always parallel to the big arm 33 .

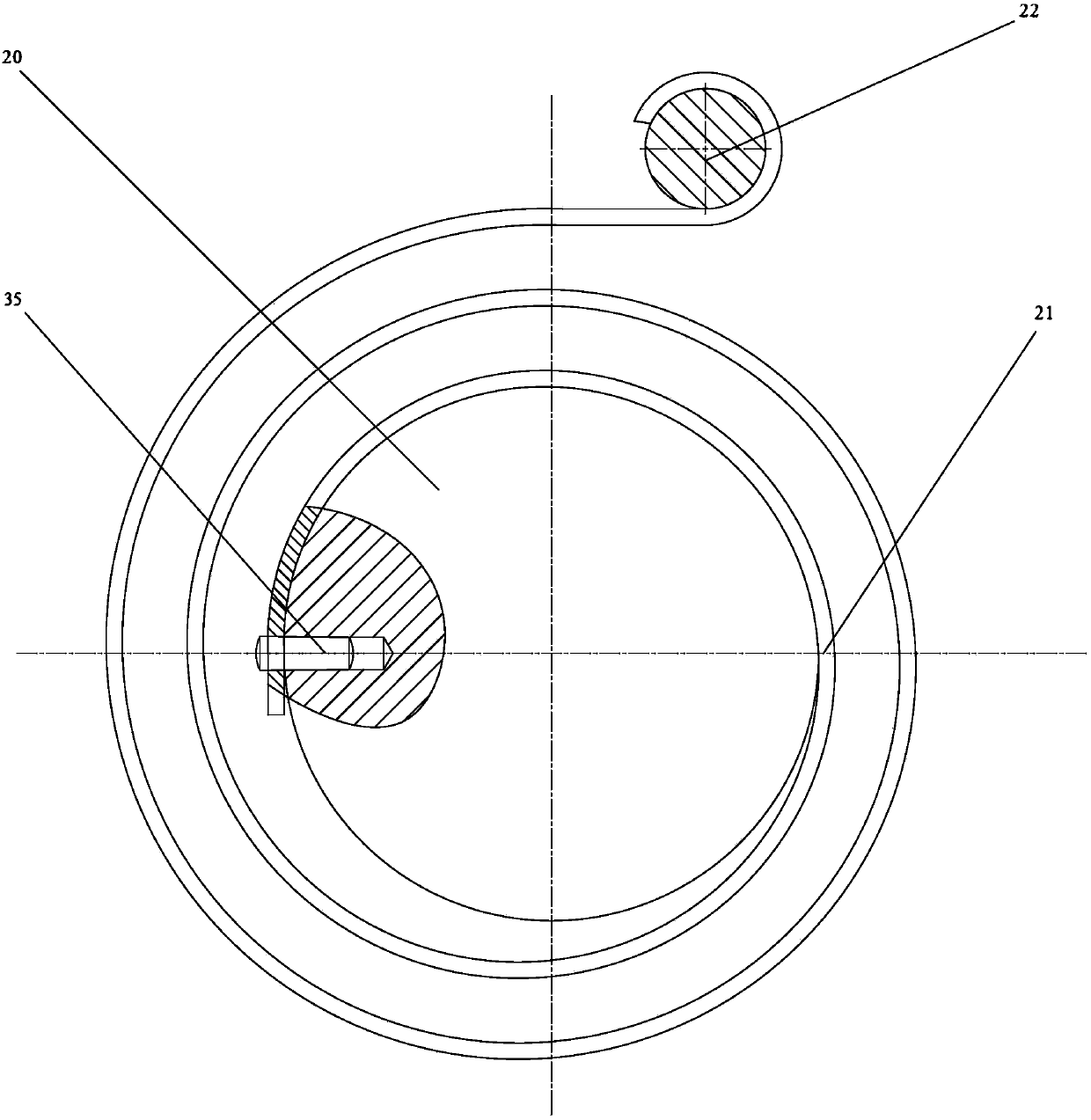

[0030] Such as Figure 6B As shown, the initial positions of the boom 33 and the small arm 32 are shown by the solid line, and the dotted line is the position after the movement. The plane scroll spring 21 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com