Double-linked safety brake system

A technology of safety brakes and brake systems, applied to bicycle accessories, bicycle brakes, etc., can solve the problems that the braking performance and safety of two-wheeled vehicles cannot be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

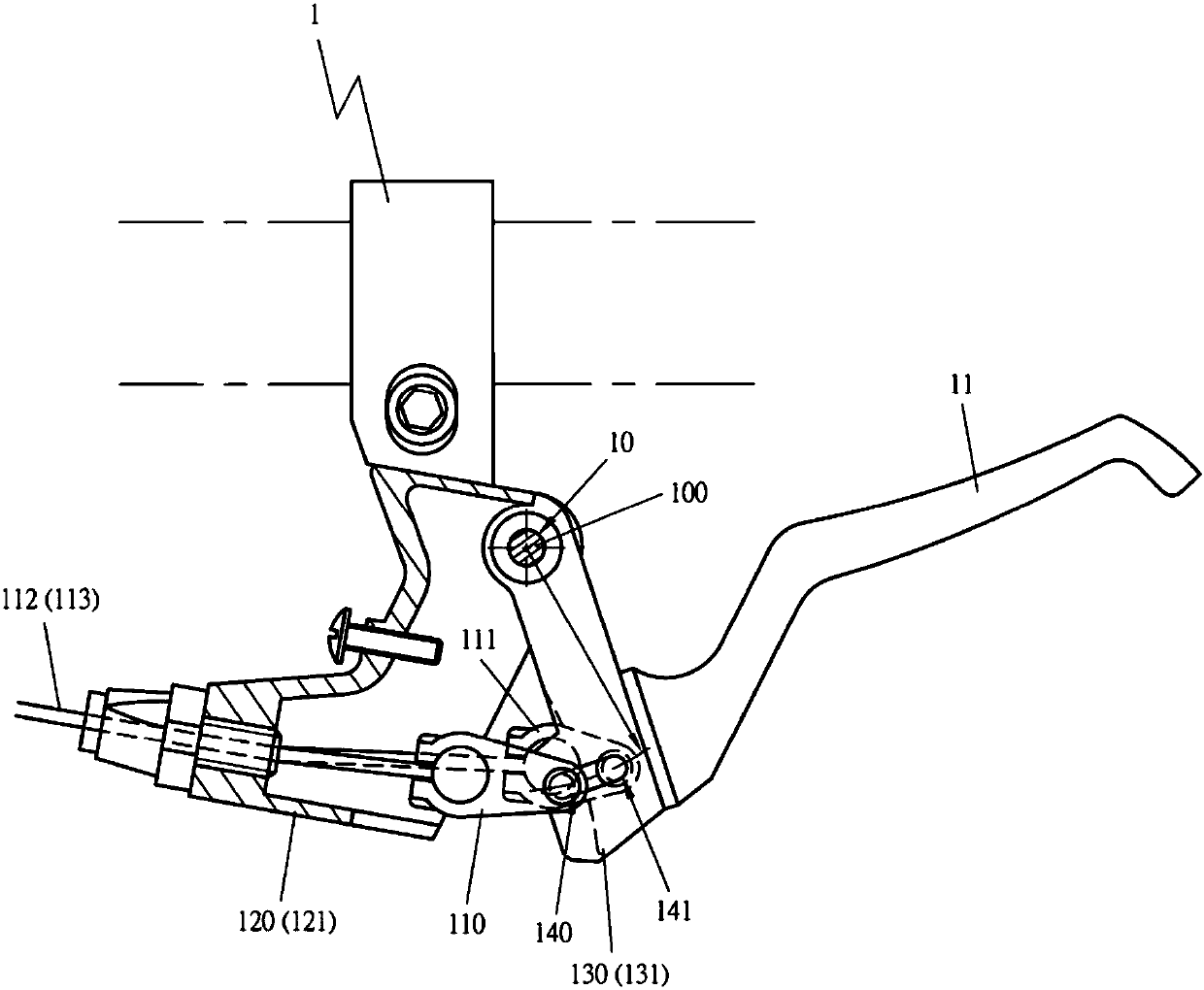

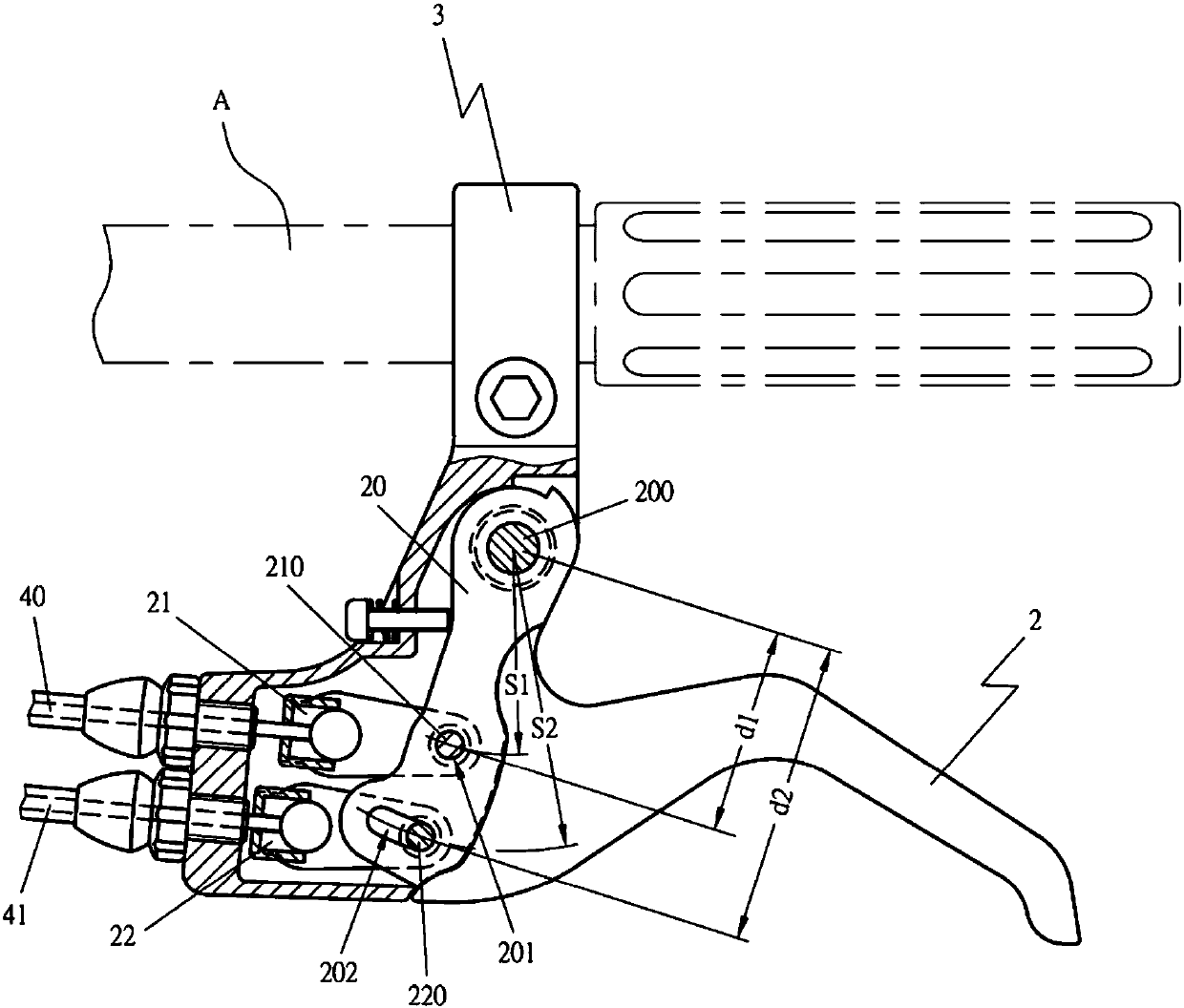

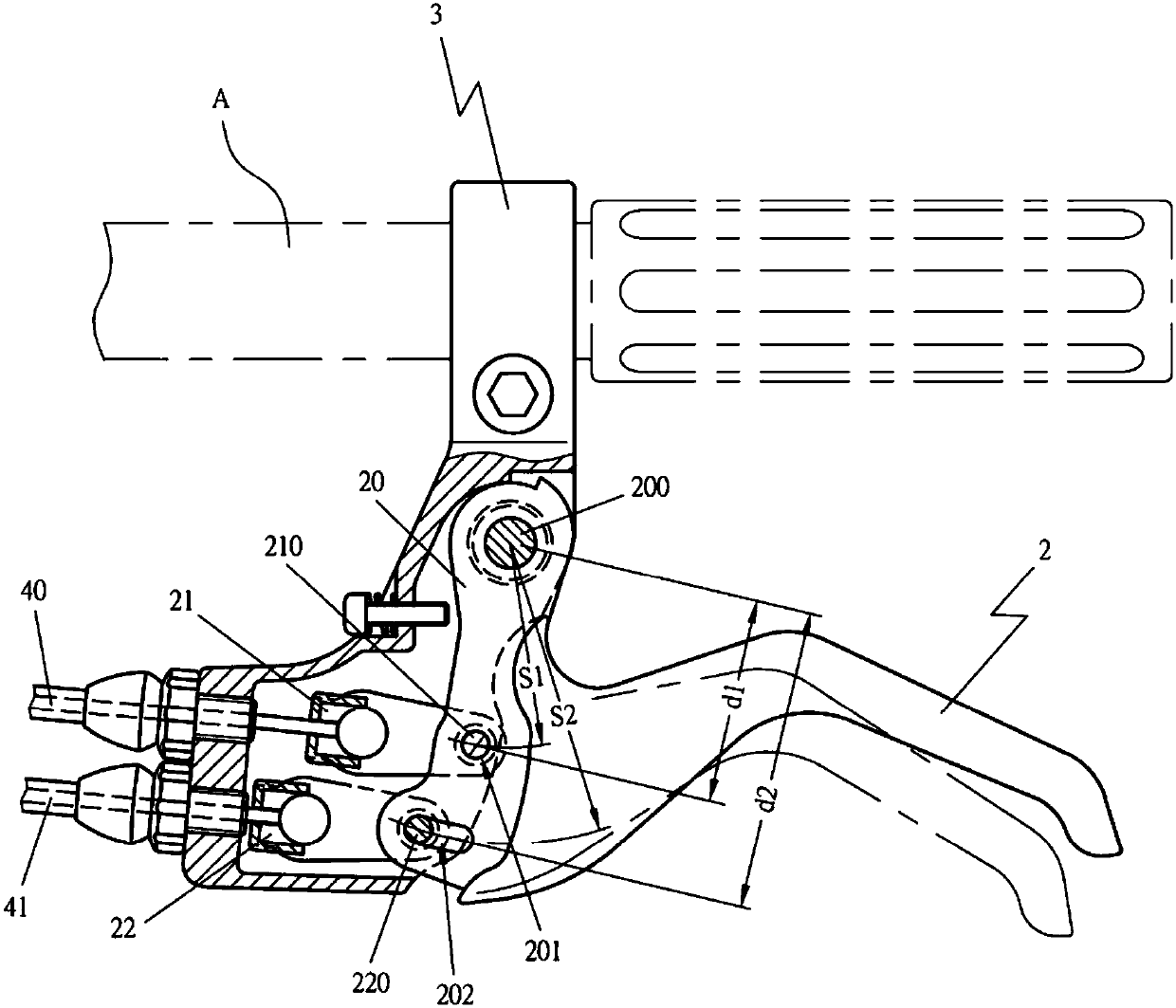

[0038] In order to enable the public to further understand the double linkage safety brake system described in the present invention, the best implementation is explained as follows according to the drawings in the description:

[0039] Such as Figure 2-4 As shown, the dual linkage safety braking system of the present invention at least includes: brake handle 2, an integrally formed driving arm 20 is provided, a supporting shaft 200 is set between the aforementioned driving arm 20 and the base 3, and the base The seat 3 is fixed on the handle A of the vehicle or at an appropriate position. The driving arm 20 is respectively provided with a first pivot hole 201 and a second pivot hole 202, the distance d1 between the first pivot hole 201 and the aforementioned support shaft 200 is shorter than the second pivot hole 202 The distance d2 from the aforementioned support shaft 200 . In this way, the circular movement distances S1 and S2 of the first connecting rod 21 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com