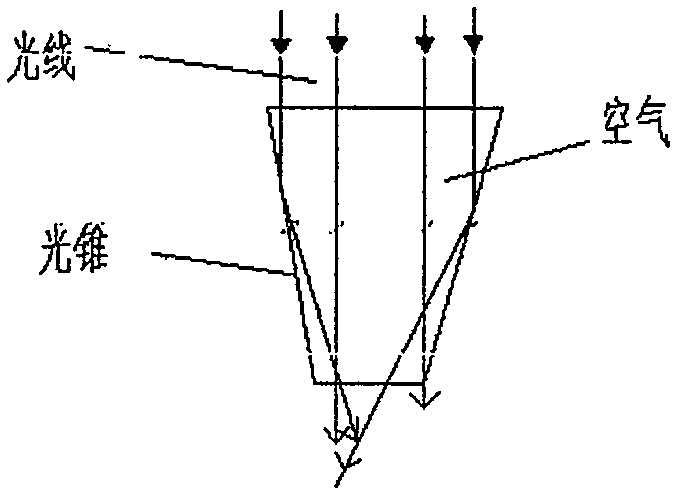

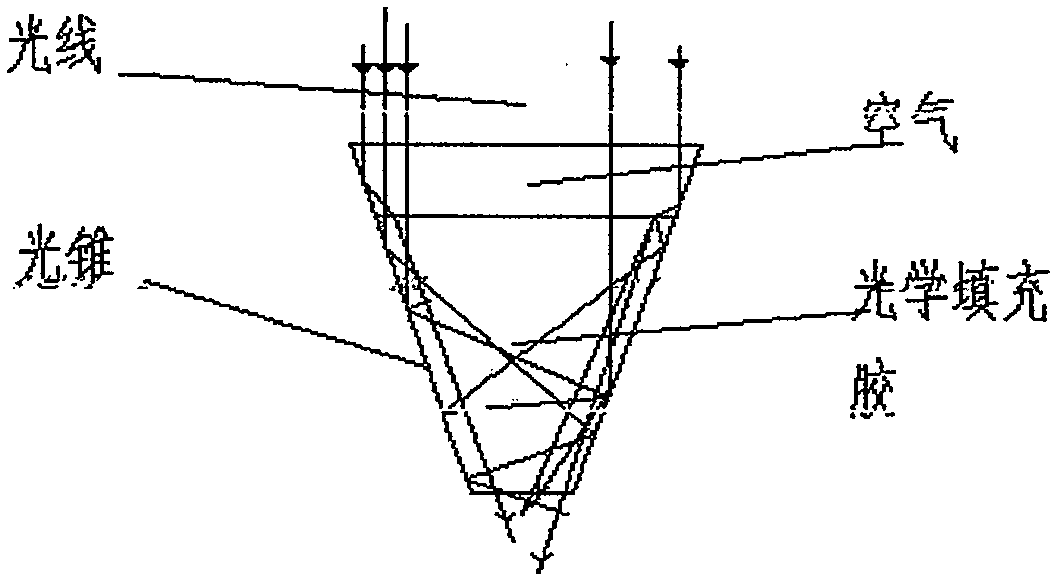

Filling adhesive for visible-light light cone

A visible light and glue-filled technology, applied in the field of chemical colloids, can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

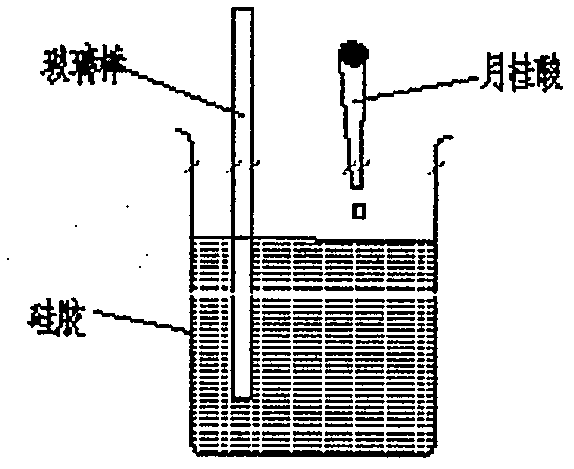

[0012] The key of the present invention's success is the preparation of filler, and the requirement of this process is:

[0013] 1.1 Add 40ml of silica gel to the beaker, heat it to 50°C and keep the temperature constant.

[0014] 1.2 Heat the calculated lauric acid crystals to 50°C to melt and prepare 10ml of lauric acid solution with a concentration of 1mol / L, and then heat to 50°C to keep the temperature constant.

[0015] 1.3 Use the gas generator to adjust the gas flow rate and the temperature to 50°C for standby.

[0016] 2 Add 1ml of lauric acid solution to the beaker and stir at a constant speed for 10min.

[0017] 3 10ml of 1,3-butadiene gas was introduced into the mixed solution. Stir at low speed and uniform speed for 10 minutes

[0018] 4 After stirring, the prepared colloid can be obtained, which needs to be filled into the light cone within 15 minutes. The optical glue cures after about 30 minutes.

[0019] All the above steps are completed in a sealed inert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com