Drum type washing machine and drum type washing and drying machine

A drum-type washing machine, washing and drying machine technology, applied in other washing machines, washing machines with containers, washing devices, etc., can solve the problems of increased box vibration and increased discomfort, and achieve the effect of preventing abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

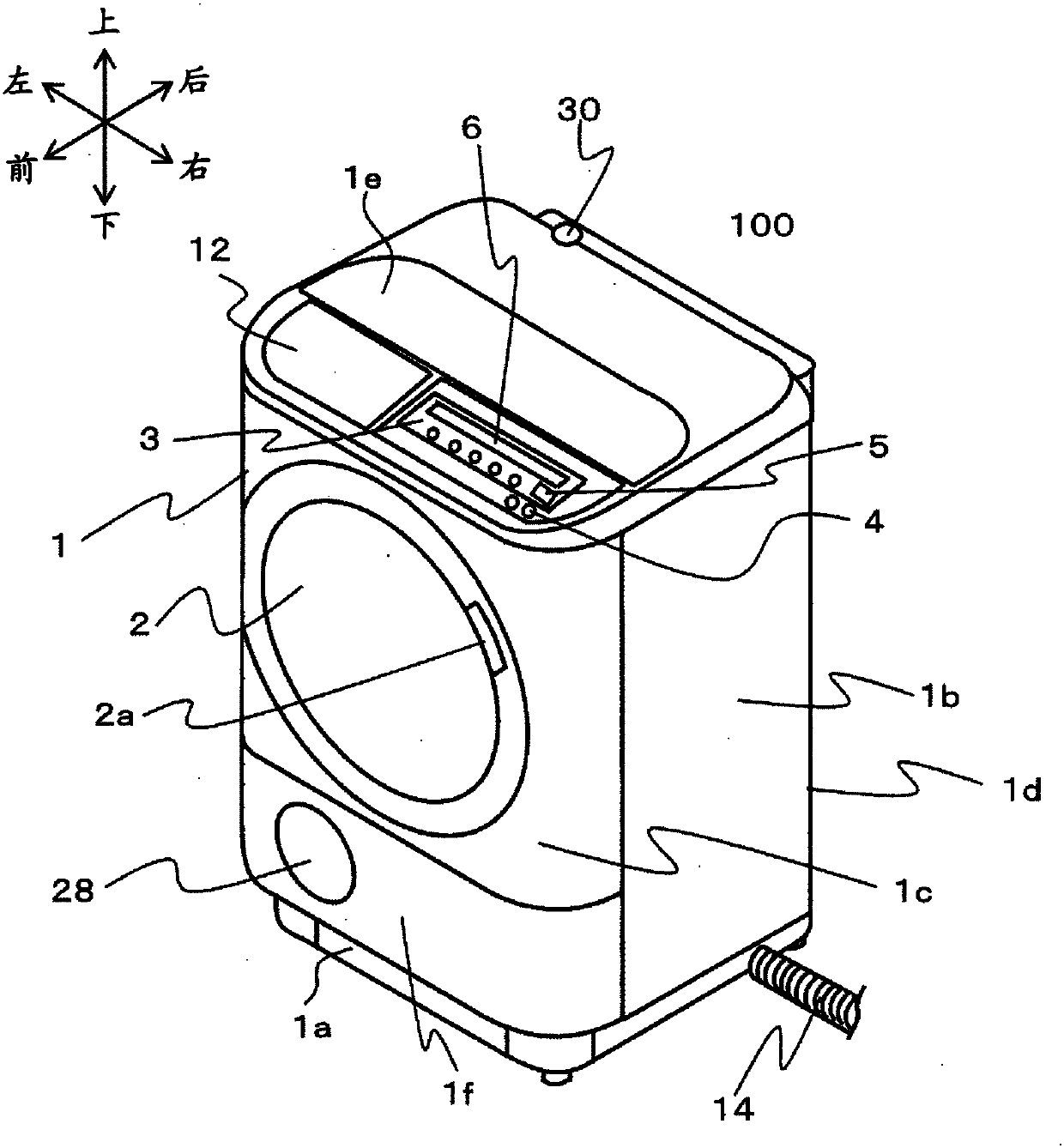

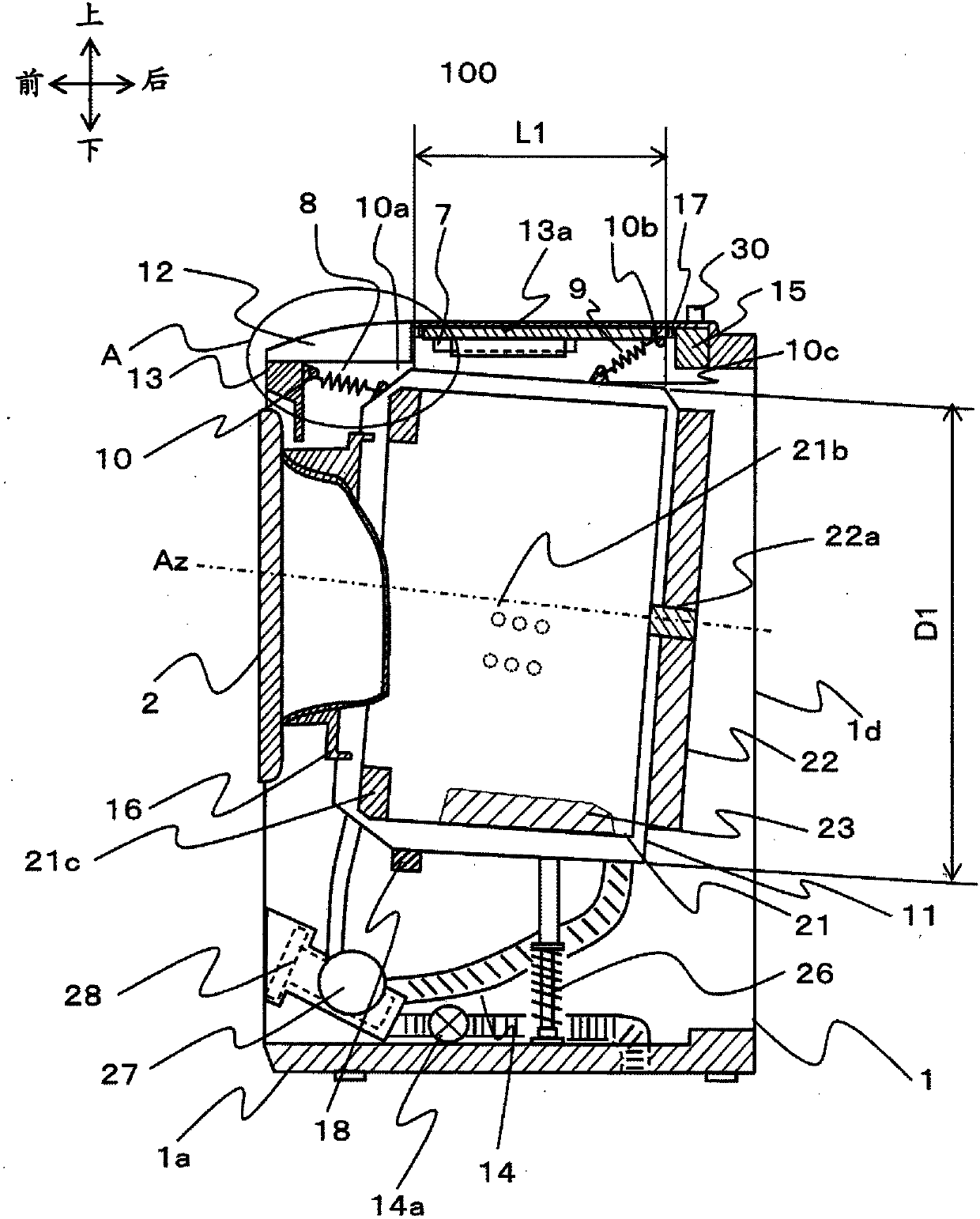

[0028] figure 1 is a perspective view showing the drum type washing machine 100 of the present invention, figure 2 It is a side view showing the internal structure of front-loading-type washing machine 100 . use figure 1 and figure 2 , the structure and operation of the front-loading washing machine 100 will be described.

[0029] constitute figure 1 The casing 1 of the outer contour of the drum type washing machine 100 shown is installed on the base 1a, and is formed by the left and right side plates 1b ( figure 1 Only the right side panel is shown in ), front cover 1c, rear cover 1d (refer to figure 2 ), upper cover 1e, and lower front cover 1f. A water supply hose connection port 30 for supplying water from a water tap to the front-loading washing machine 100 is provided on the upper cover 1e. The box body 1 forms a box-shaped outer frame including the base 1a, and has sufficient strength as the outer frame.

[0030] The door 2 closes an inlet (not shown) provide...

Embodiment 2

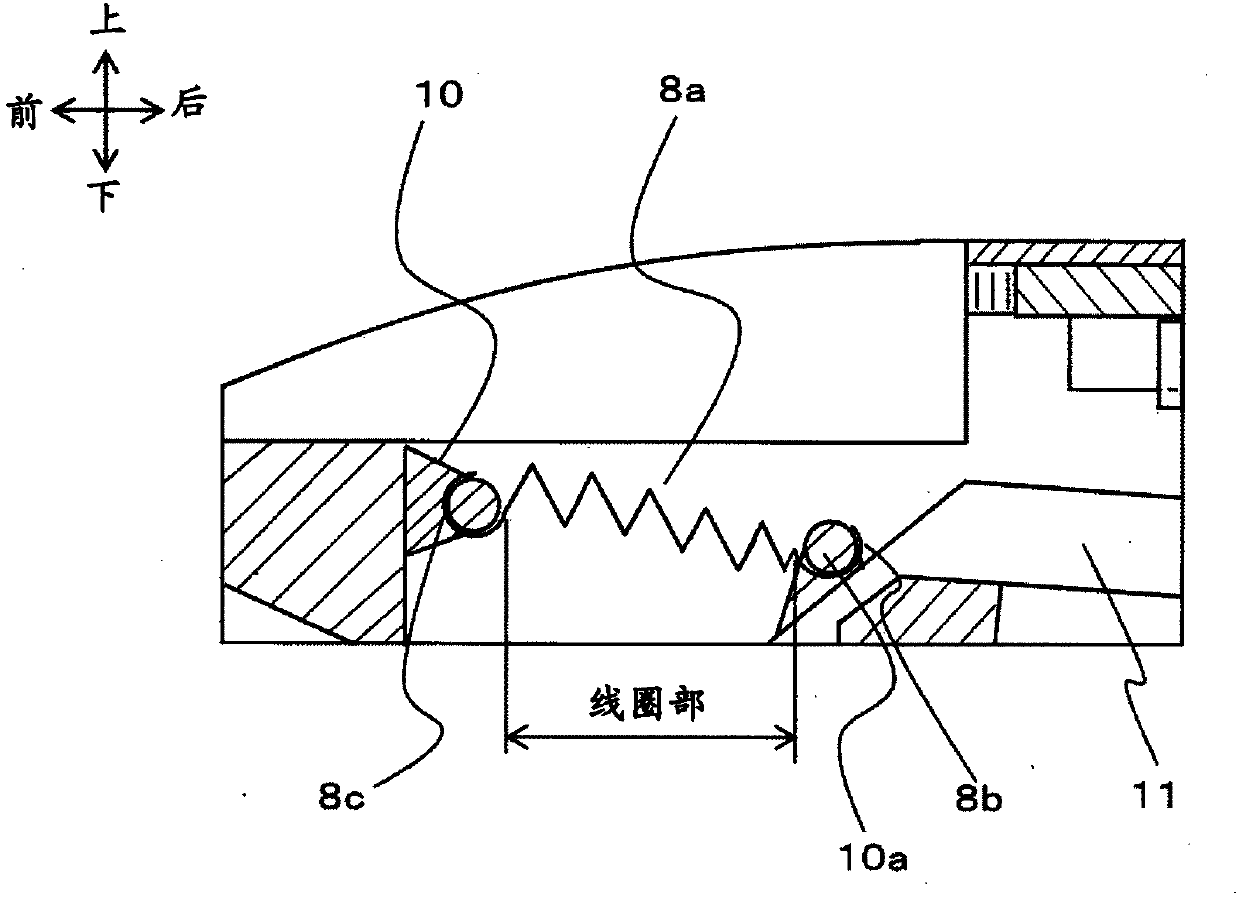

[0055] Next, refer to Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 as well as Figure 9 Example 2 will be described in detail.

[0056] In addition, since front-loading-type washing machine 100 has basically the same structure as that of Embodiment 1, different parts will be described below.

[0057] Figure 4 A central cross-sectional view of the drum-type washing machine 100 of the present embodiment is shown, Figure 5 A state in which the outer tank 11 is statically supported is shown. In Embodiment 2, the outer groove side anti-falling member 31 is arranged in front of the outer groove side rear spring bracket 10c, and the box side anti-falling member 31a is arranged in front of the outer groove side anti-falling member 31. The distance between the outer tank side anti-off part 31 and the box side anti-off part 31a is as follows: before the outer tank 11 is moved forward from the state where the outer tank 11 is statically supported, the first suspensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com