Washing machine balance ring and washing machine with the same

A balance ring and washing machine technology, which is applied in the field of washing machines, can solve the problems that the convex edges and corners of the appearance affect the safety and beauty, and the balance ring affects the service life, etc., so as to avoid safety hazards and insufficient aesthetics, increase use safety and satisfaction, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

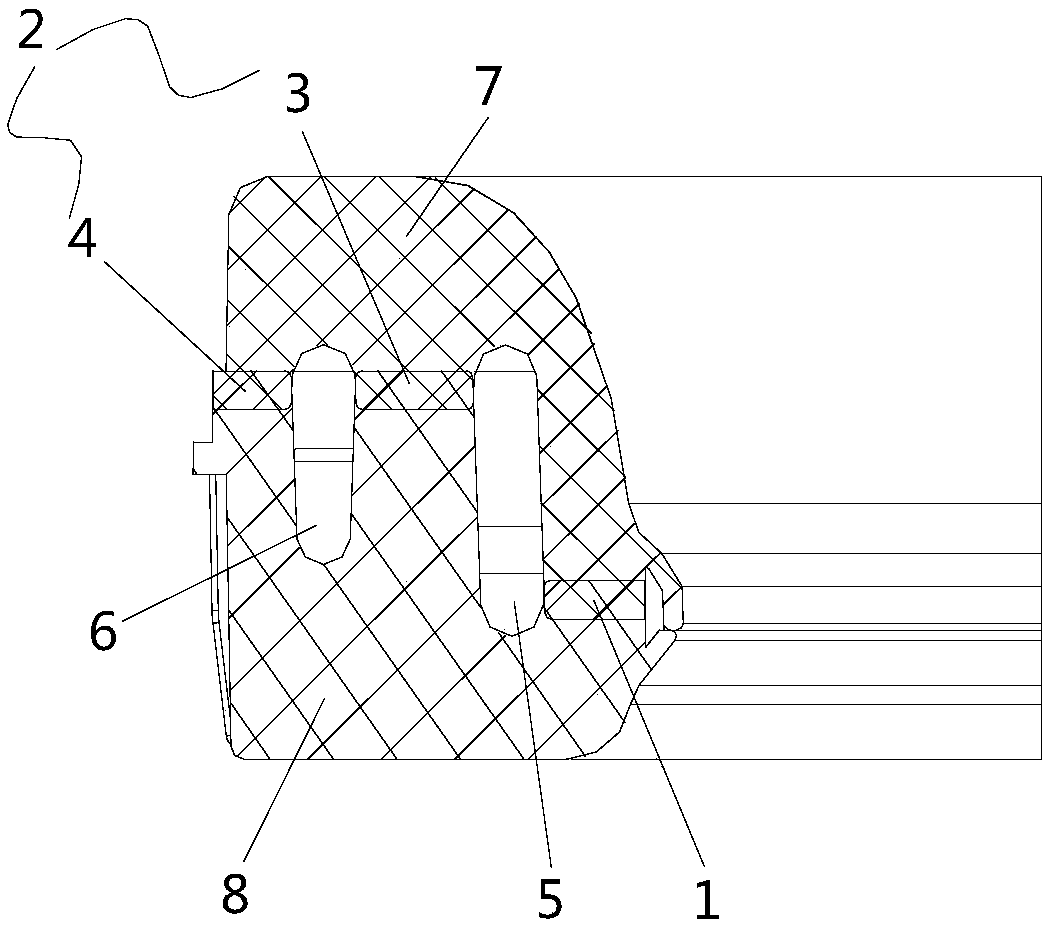

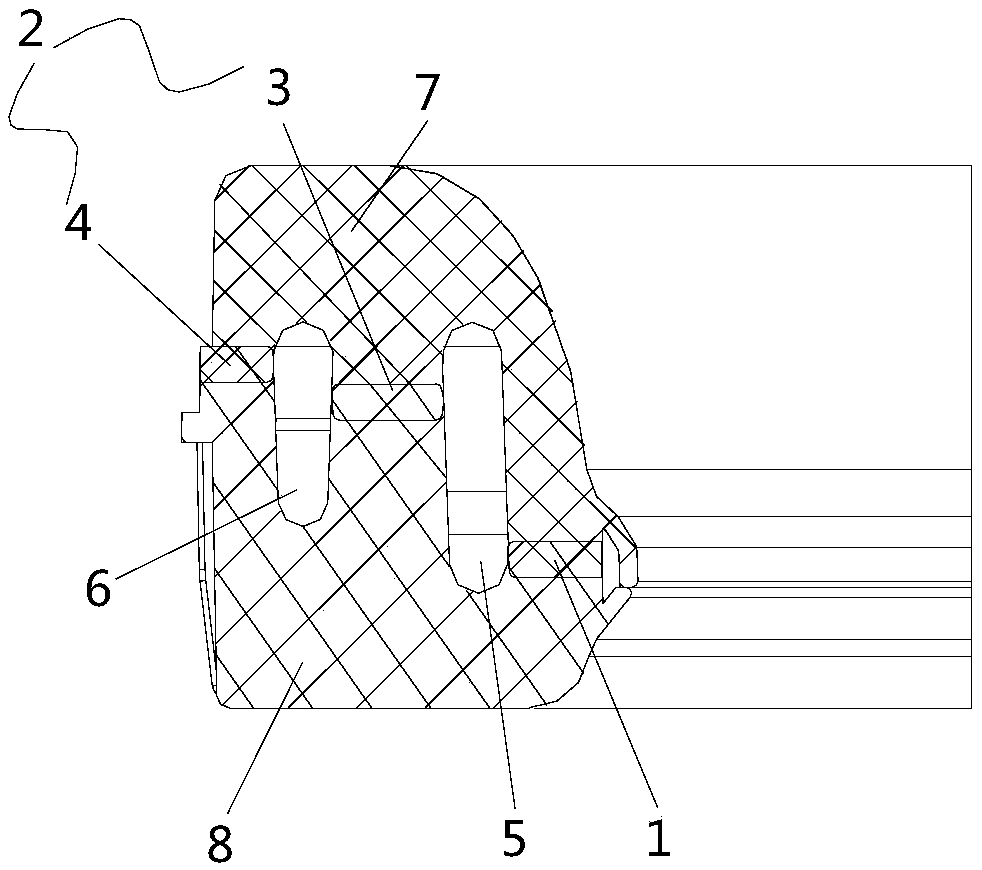

[0051] Such as figure 2 As shown, the example described in this example is figure 1 As shown, the balance ring of a washing machine in the present invention includes a first balance part 7 and a second balance part 8, and the first balance part and the second balance part are clad to form a sealed cavity, and the sealed cavity includes The first welding surface 1 near the inside of the ring and the second welding surface 2 near the outside of the ring, the first welding surface 1 and the second welding surface 2 are not on the same level; the inner surface of the balance ring A smoothly transitioned curved surface is formed from the first balance part 7 to the second balance part 8, and those skilled in the art can understand this setting as the height of the first welding surface 1 higher than the second welding surface 2, or as The height of the first welding surface 1 is lower than the second welding surface 2, the specific situation is selected and set according to the a...

Embodiment 2

[0057] Such as figure 2 As shown, this embodiment is a further limitation of the first embodiment above. The cross-sections of the inner welding surface 3 and the outer welding surface 4 in this embodiment are not on the same horizontal plane. Above all, the arrangement of the second welding surface 2 , the inner welding surface 3 , and the outer welding surface 4 on different horizontal planes can effectively absorb the impact of the centrifugal force on the balance ring.

Embodiment 3

[0059] Such as figure 1 As shown, this embodiment is a further limitation of the first embodiment above. In this embodiment, on the cross-section of the inner cavity of the balance ring, the cross-sections of the inner welding surface 3 and the outer welding surface 4 are at the same level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com