Water-spraying and dust-falling deceleration strip system

A technology of speed bumps and dust suppression, which is applied in the direction of roads, road surface cleaning, road signs, etc., can solve the problems of excessive dust, heavy water spraying and moisturizing tasks, time-consuming and labor-intensive problems, and achieve the effect of reducing dust and solving the effect of water spraying powerlessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

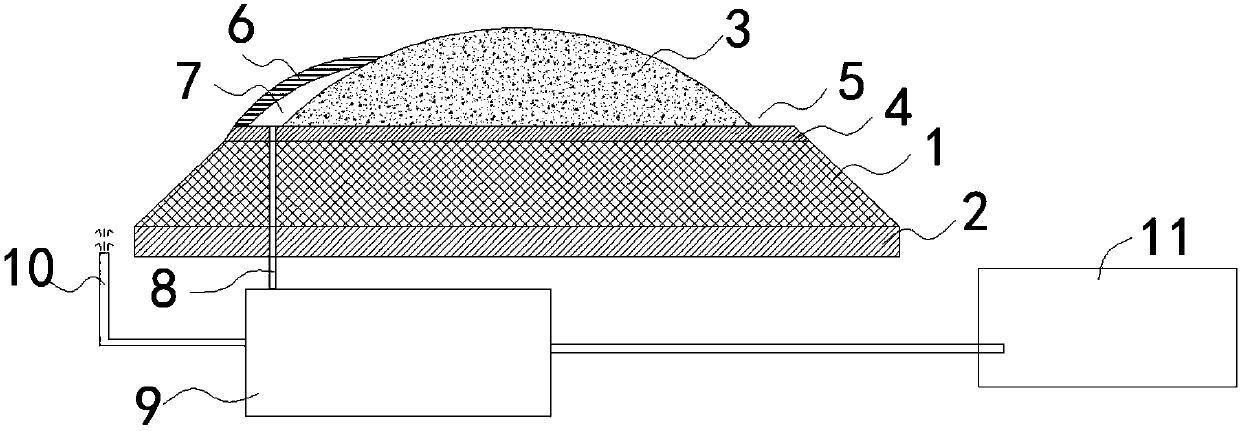

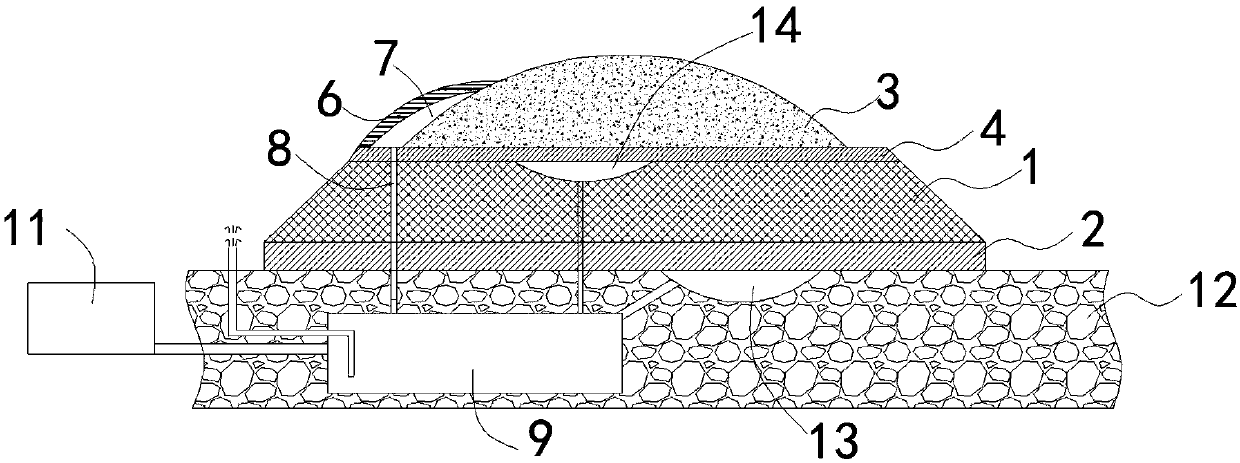

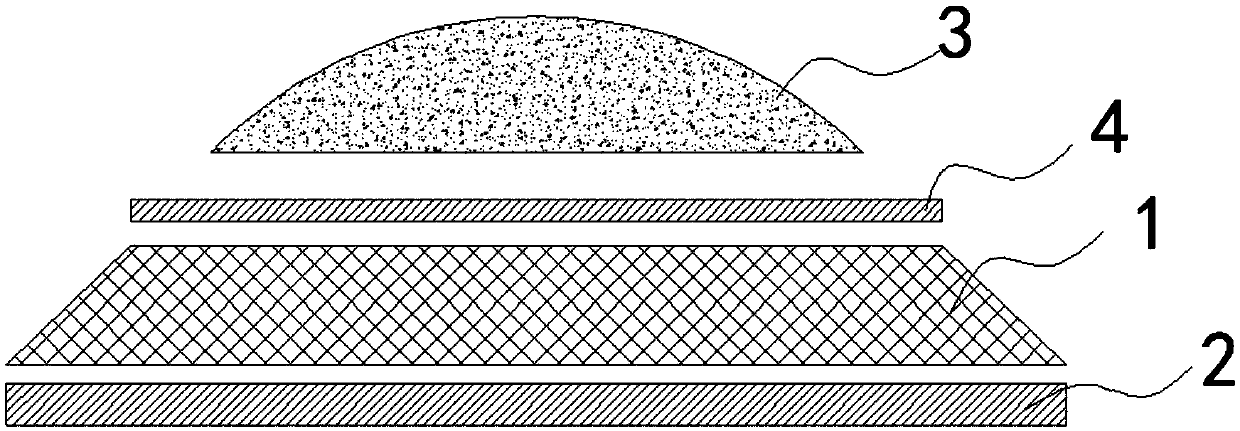

[0028] Such as figure 1 , 2 , 3 and 4, a water-spraying and dust-reducing speed bump system includes a speed bump body and a water spray module; the speed bump body includes:

[0029] The base 1 fixed on the road surface has a trapezoidal cross-section, and the upper plane of the base is smaller than the lower plane and parallel to each other. The upper plane of the base is provided with a plurality of through holes penetrating to the lower plane so that the base forms a honeycomb structure. The base of the honeycomb structure is conducive to weight reduction and has a shock absorption function. It should be noted that the position of the second depression on the upper plane is not Set vias.

[0030] The first elastic layer 2 arranged between the base 1 and the road surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com