Angular Contact Ball Bearings and Transmission Components

An angular contact ball bearing and rolling bearing technology, applied in the direction of rolling contact bearings, ball bearings, bearing components, etc., can solve the problems of reducing friction and expensive manufacturing of bearings, and achieve the advantages of increased stability, easy operation and simplified operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

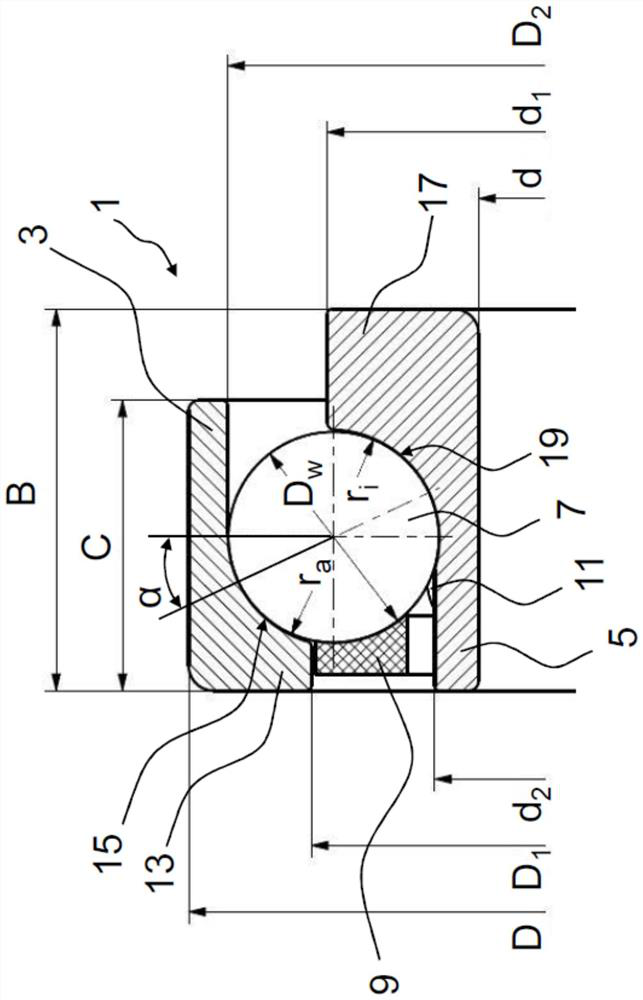

[0045] in figure 1 In this, an angular contact ball bearing 1 according to a preferred embodiment of the present invention is shown. The angular contact ball bearing 1 includes an outer ring 3 and an inner ring 5, and a ball 7 is arranged between the outer ring 3 and the inner ring 5. The ball 7 is held by the cage 9. The outer ring 3 is formed with a shoulder 13 facing inward in the radial direction, and a raceway 15 for the ball 7 is formed from the inner side of the shoulder 13. Similarly, on the inner ring 5, a shoulder 17 facing the radially outer side is formed, and starting from the inner side of the shoulder 17, a raceway 19 for the ball 7 is formed. Ball 7 is in contact area with radius r a Raceway 15 and radius r i The raceway 19 is close (osculateon). The close here is chosen to be significantly narrower than the angular contact ball bearings of known designs, thereby enabling better compression. In order to further optimize the compression, it is preferable to h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com