Second-generation tapered roller bearing of speed reducer industry

A technology of tapered roller bearings and reducers, which is applied in the field of bearings, can solve the problems that the machining accuracy of the spacer ring affects the installation accuracy, etc., and achieve the effects of compact structure, improved load distribution, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

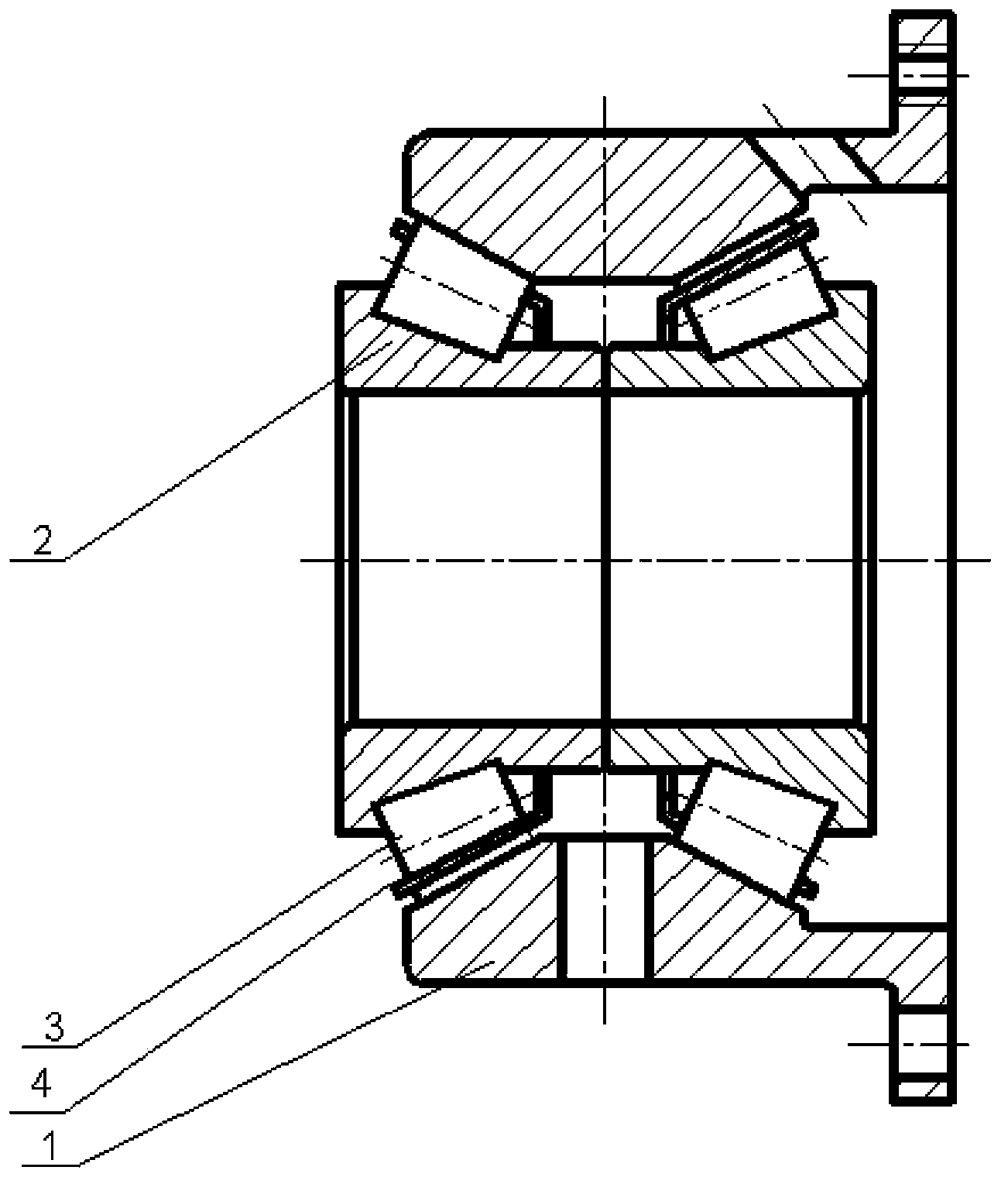

[0018] Such as figure 1 As shown, a second-generation tapered roller bearing in the reducer industry includes an inner ring 2, an outer ring 1, a roller 3 and a cage 4. The cage 3 installs the rollers in its pockets and is connected with After the inner ring 2 is connected, it is put into the double-row raceway of the outer ring 1 together.

[0019] The outer ring 1 is a flange structure, and is provided with an oil filling hole communicating with the inner ring 2 . There are two inner rings 2, and the outer walls of the two inner rings 2 form a back-to-back raceway structure. The outer ring 1 is an outer ring made of spring steel after surface quenching. The bearing should form a certain torque.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com