Damage detecting method of platy structure

A damage detection and plate shape technology, which can be used in measuring devices, analyzing solids using sonic/ultrasonic/infrasonic waves, and using sonic/ultrasonic/infrasonic waves for material analysis. and other problems to achieve the effect of weakening the impact, avoiding potential safety hazards, and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

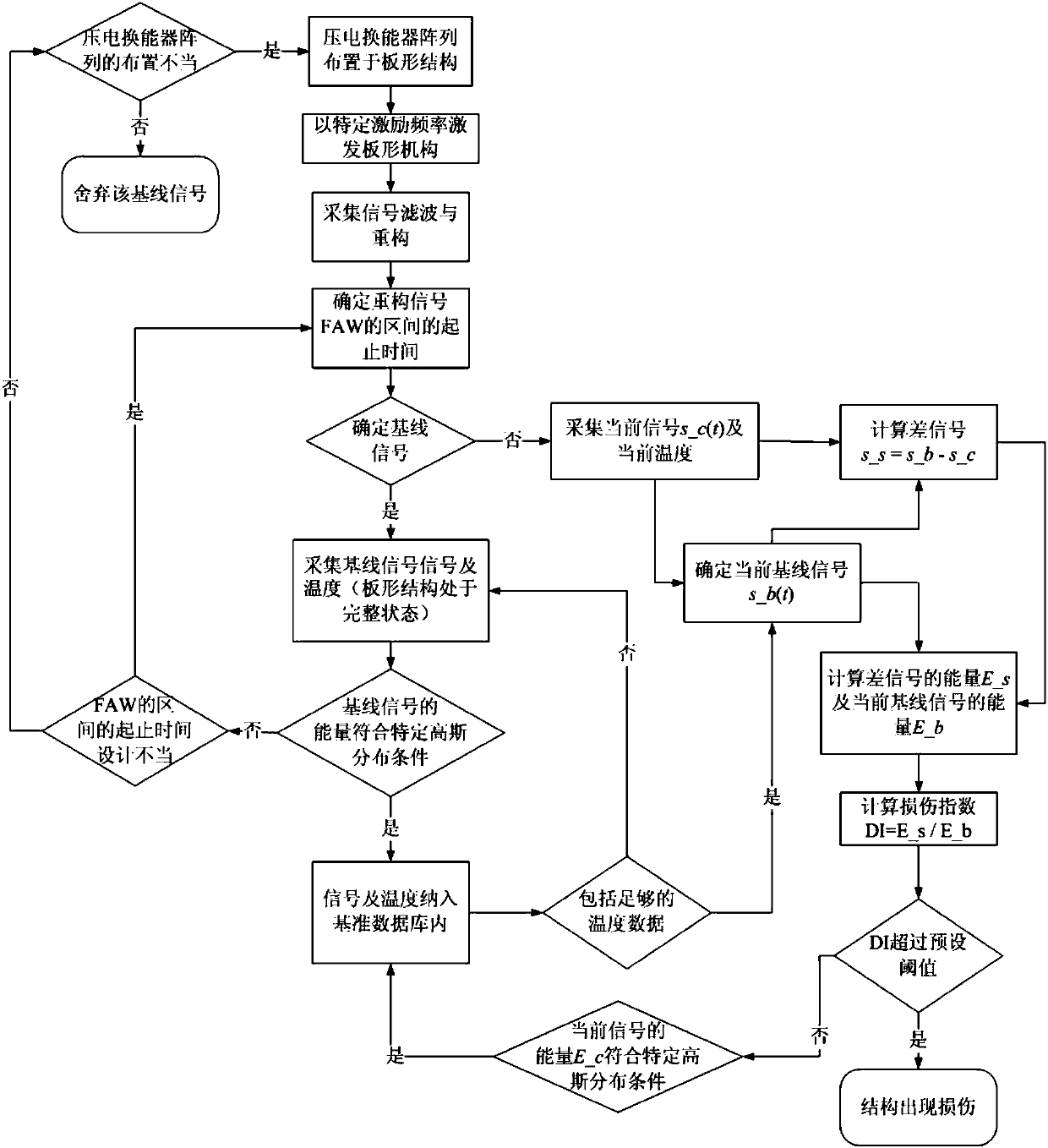

[0034] An embodiment of the present invention provides a damage detection method for a plate structure, the method includes the following steps:

[0035] S1: The piezoelectric transducer array is arranged in a plate-shaped structure;

[0036] S2: Establish a benchmark database:

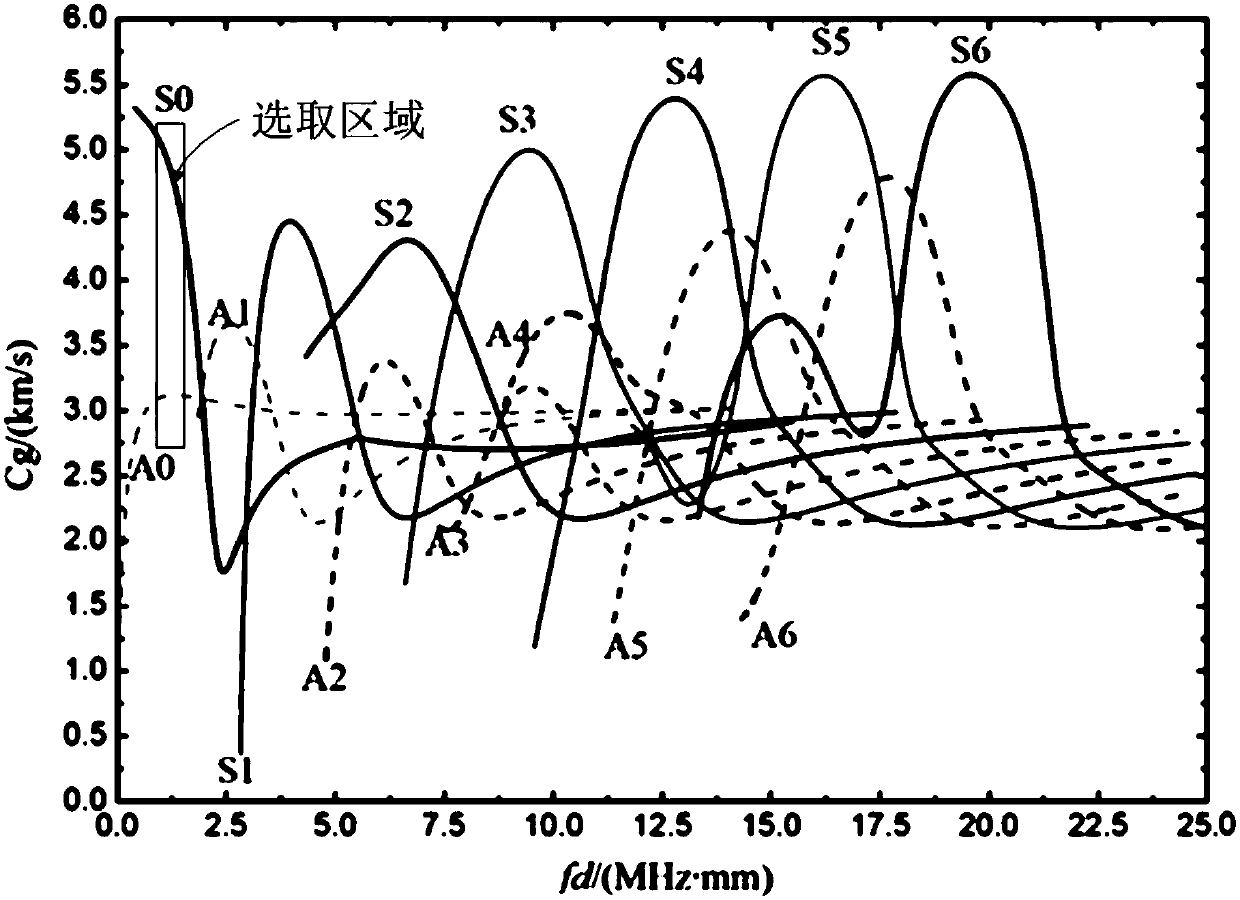

[0037] (1) The piezoelectric transducer excites the undamaged plate-shaped structure at a specific excitation frequency to generate Lamb waves;

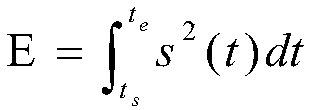

[0038] (2) collect multiple sets of baseline signals and their corresponding temperatures, each baseline signal is the eigenvalue of the first arriving wave of the Lamb wave;

[0039] (3) Store each group of baseline signals and their corresponding temperatures in the benchmark database;

[0040] S3:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com