Improved vermicomposting toilet facility

A toilet and composting technology, applied in organic fertilizers, sanitation equipment, fertilization equipment, etc., can solve the problems of expensive and difficult transportation, and achieve the effect of small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

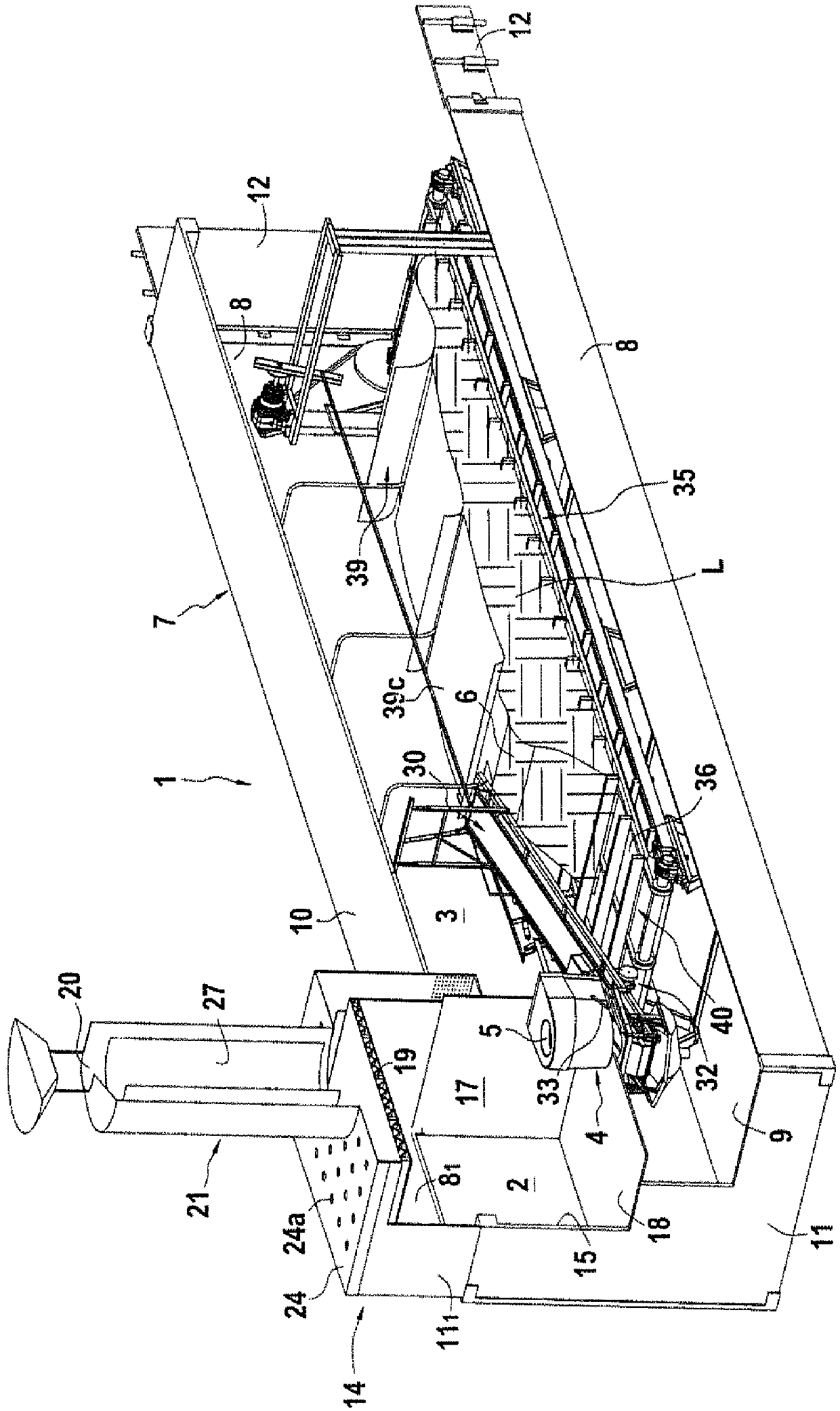

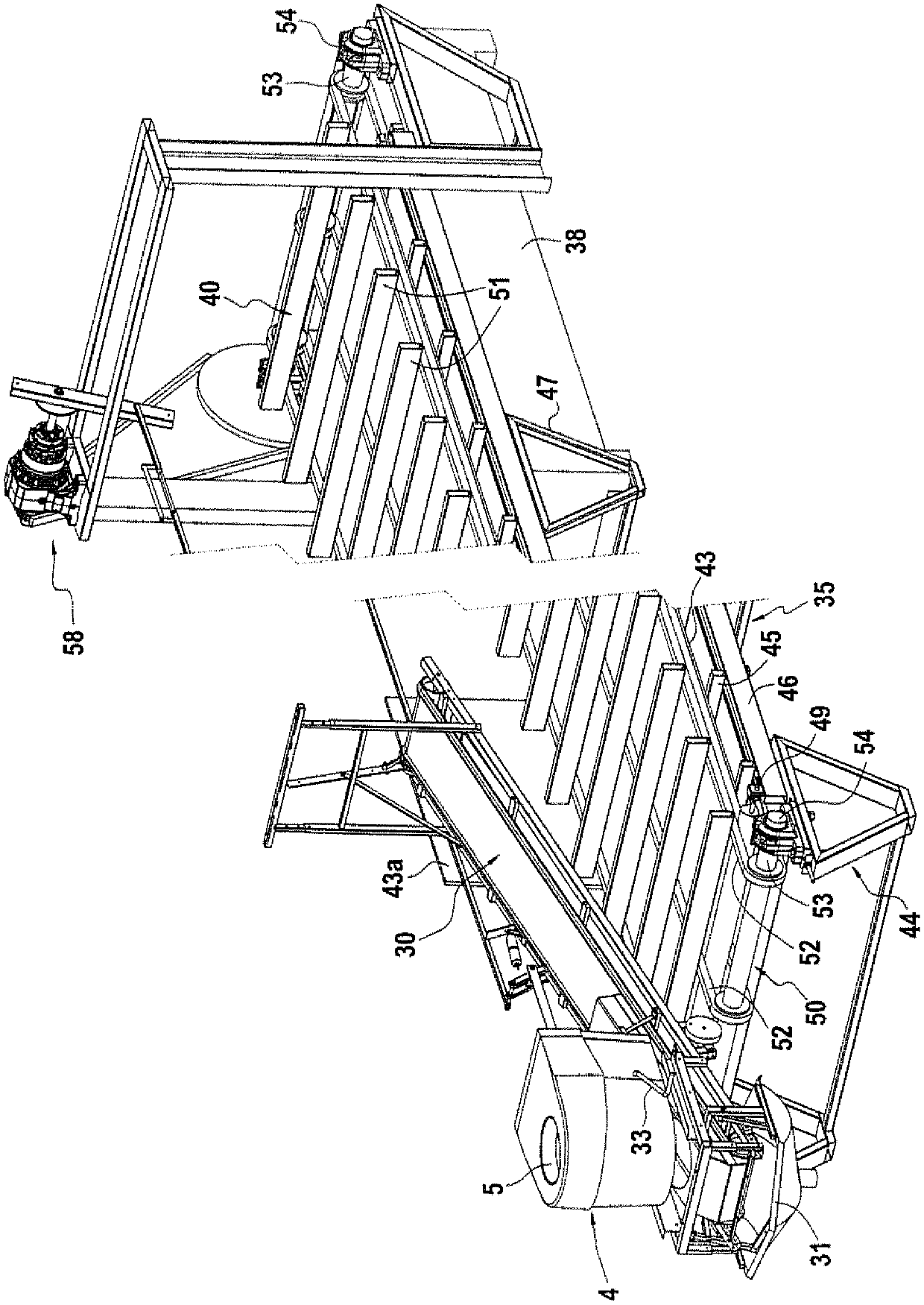

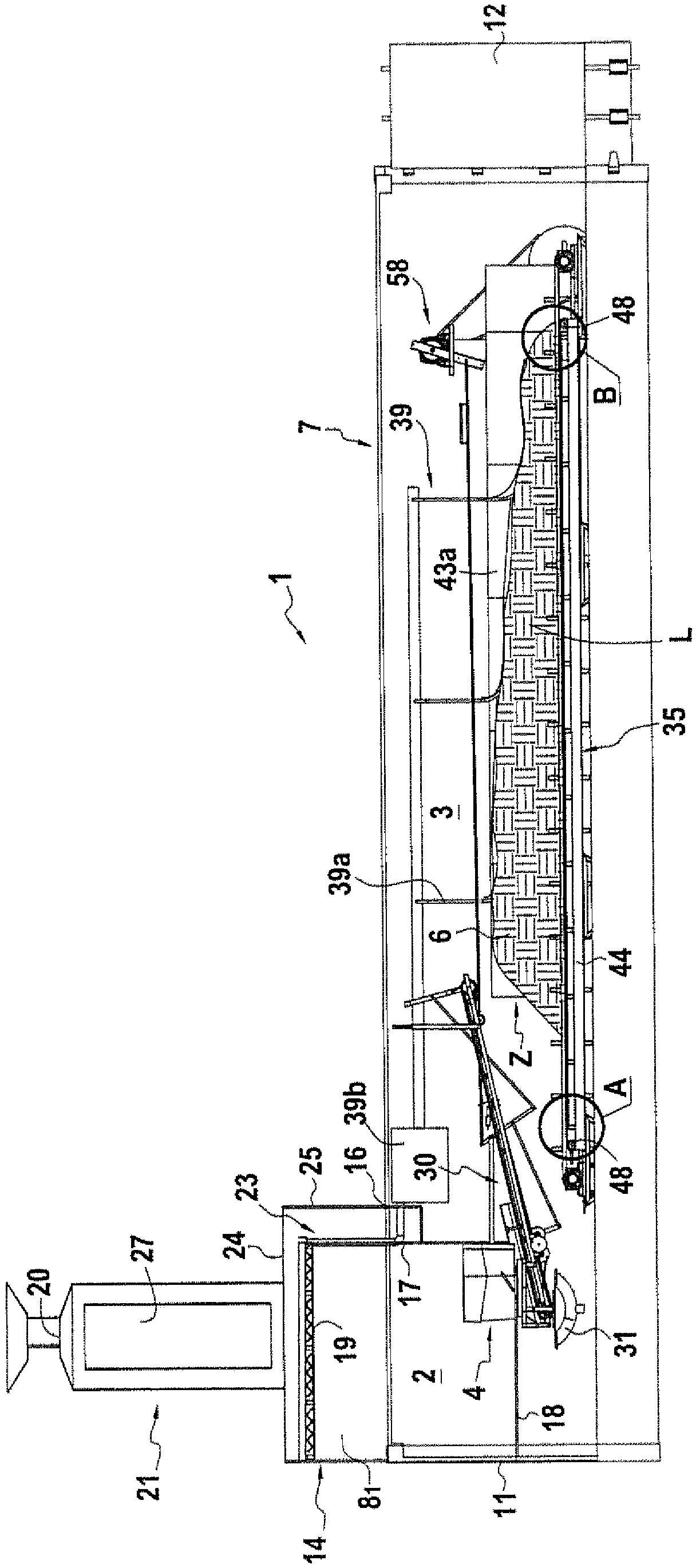

[0029] As can be seen from the figures, the invention relates to a so-called "dry" toilet installation 1 having at least one toilet 2 adjacent to or near a treatment chamber 3 (and in the Figure 1 to Figure 3 only one of the shown examples). In particular, toilets 2 are usually provided with a device 4 having a gravity drain 5 firstly for liquid outflows such as urine and secondly for solid waste 6 consisting of faeces and toilet paper. Typically, the treatment chamber 3 recovers at least solid waste, but typically also liquid effluent.

[0030] exist Figure 1 to Figure 4 In the example shown, the device 4 is a toilet, but it should be clear that the device 4 could be implemented in the form of a squatting toilet.

[0031] According to the characteristics of the invention, the form of the structure of the toilet equipment 1 of the invention can be transported by road, by rail or by sea. Advantageously, this transportable structure comprises a dry freight container 7 of 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com