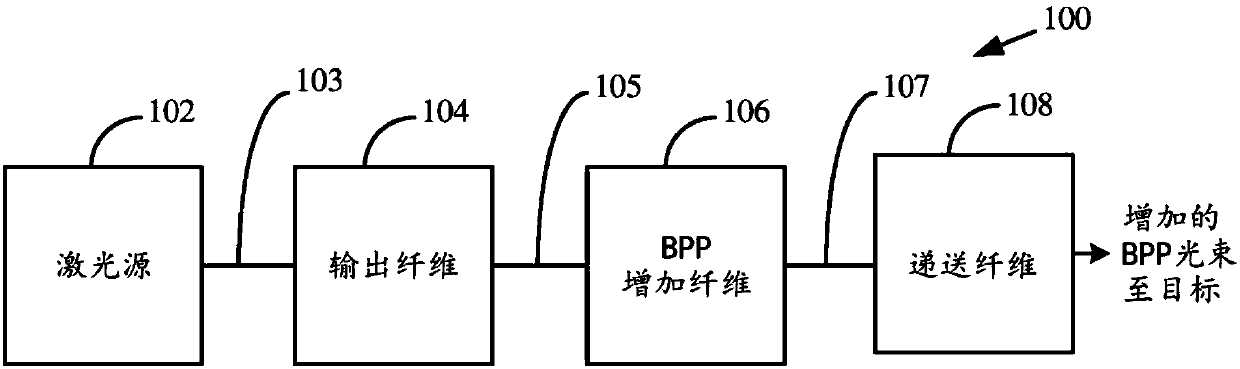

Fiber with depressed central index for increased beam parameter product

A technology of parameter product and refractive index, applied in the direction of multi-layer core/cladding optical fiber, cladding optical fiber, optics, etc., can solve the problems of lacking and reducing beam quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

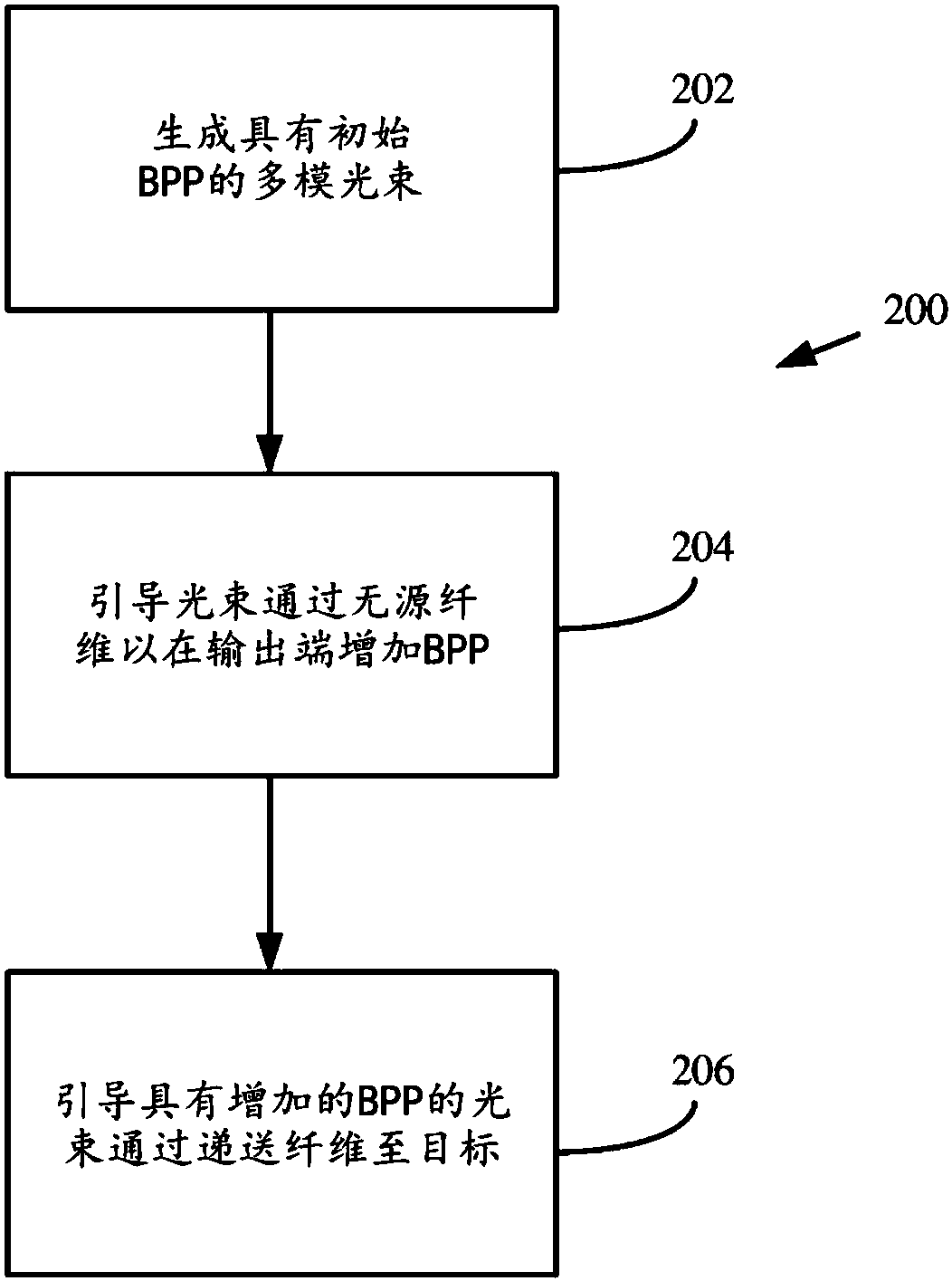

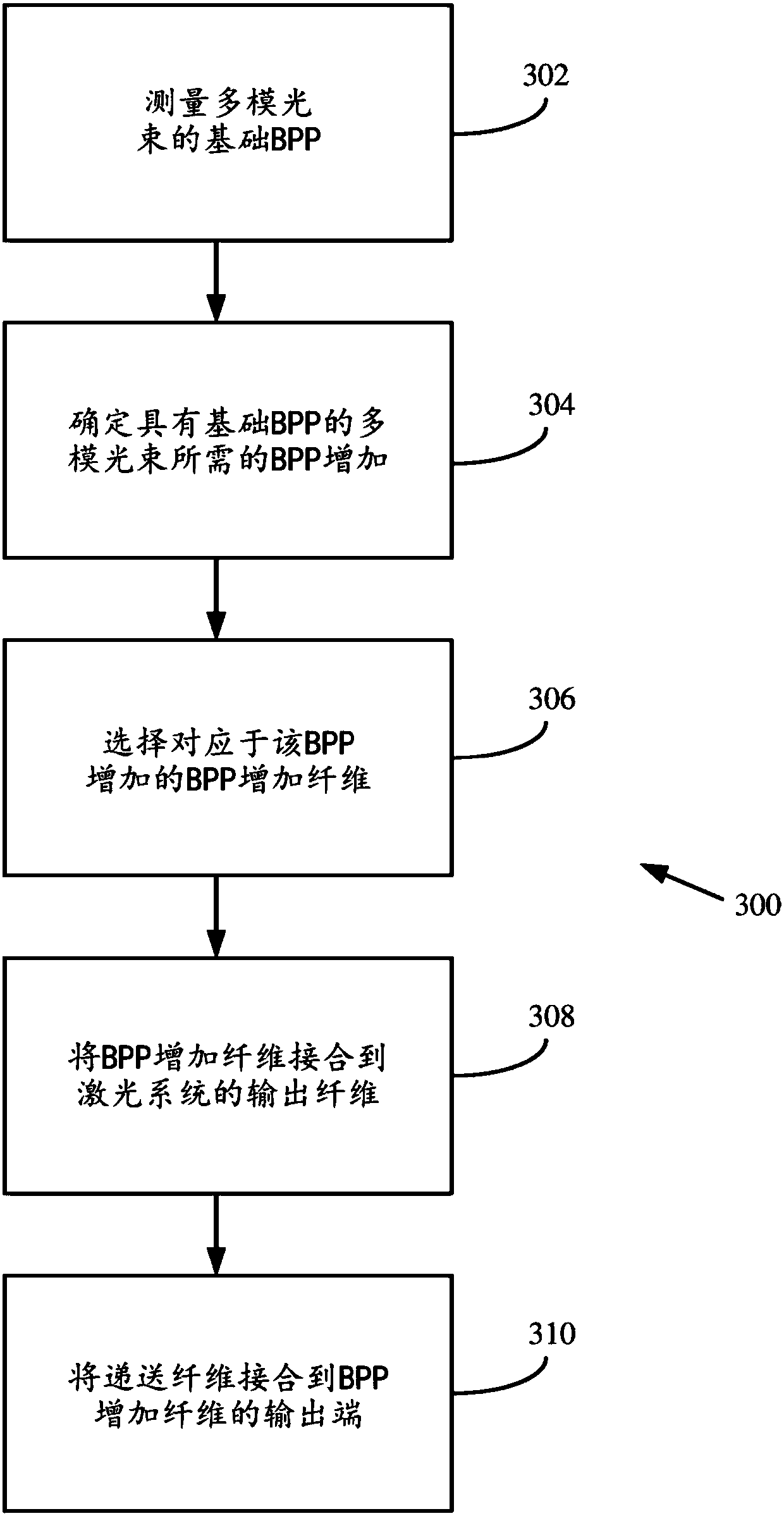

Method used

Image

Examples

Embodiment Construction

[0016] As used in this application and in the claims, the singular terms "a," "an," and "the" include the plural unless the context clearly dictates otherwise. Furthermore, the term "includes" means "includes." Furthermore, the term "coupled" does not exclude the presence of intervening elements between coupled items.

[0017] The systems, apparatus, and methods described herein should not be construed as limiting in any way. On the contrary, the present disclosure relates to all novel and non-obvious features and aspects of the various disclosed embodiments, individually and in various combinations and subcombinations with each other. The disclosed systems, methods, and apparatus are not limited to any particular aspect or feature, or combination thereof, nor do the disclosed systems, methods, and apparatus require any one or more particular advantages or problems to be solved. Any theory of operation is provided for ease of explanation, but the disclosed systems, methods a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com