Waste PCB electronic component lossless automatic separating equipment and control method thereof

A technology of electronic components and PCB boards, which is applied in the field of non-destructive automatic separation devices for waste PCB board electronic components. Good safety, guaranteed vibration and separation effects, and improved integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

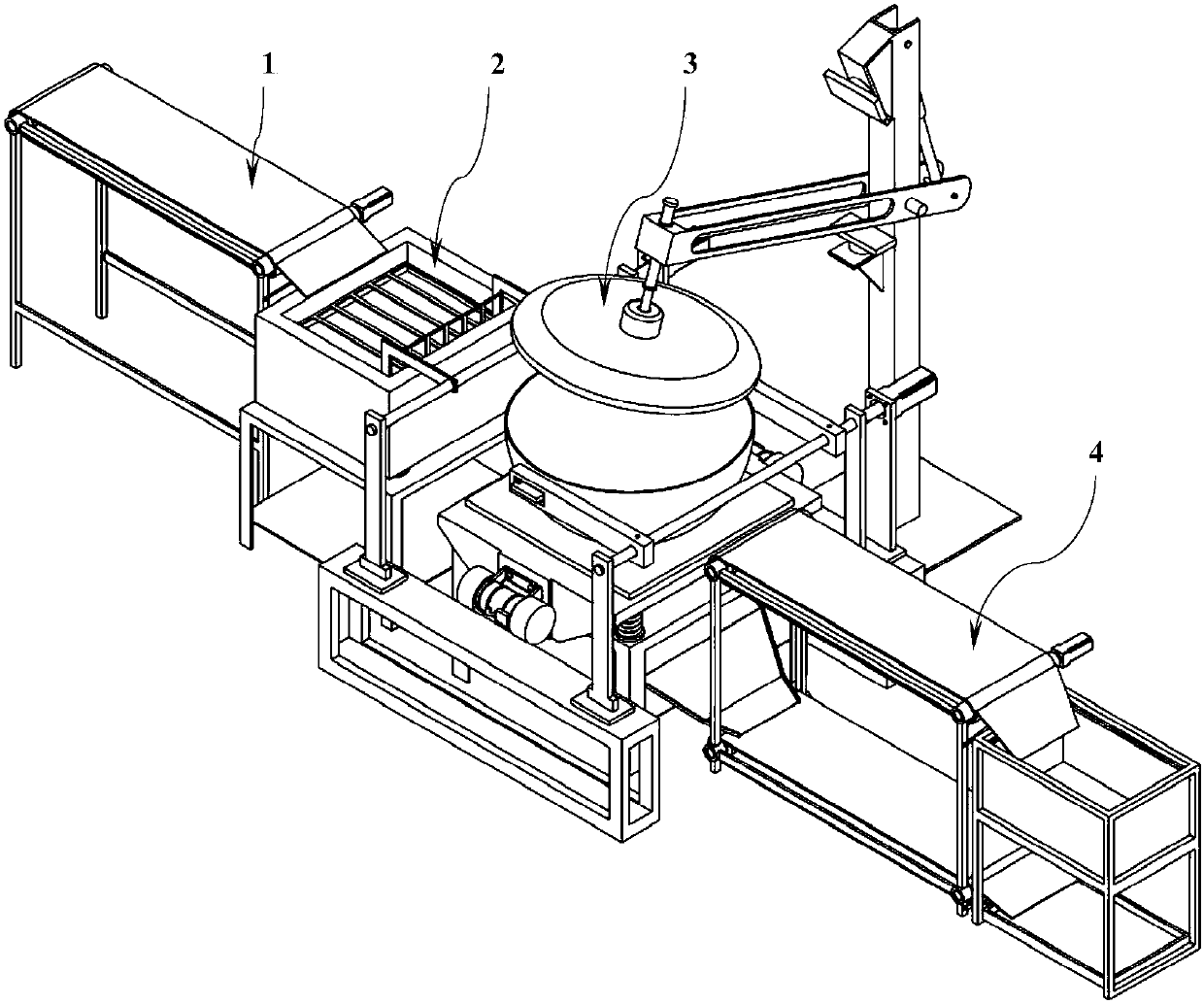

[0040] see figure 1 In this embodiment, the structural form of the non-destructive automatic separation equipment for waste PCB board electronic components is that the separation equipment is arranged in the form of "one", and from left to right are feeding device 1, heating device 2, separating device 3 and discharging device 4 .

[0041] Both the feeding device 1 and the discharging device 4 are belt conveyors. The PCB board with electronic components is fed into the heating device 2 through the feeding device 1 to heat up the welding surface, and then the electronic components are separated by the separation device 3. The produced PCB light boards and electronic components are transferred and discharged separately by the transmission belts on different levels in the discharge device 4 .

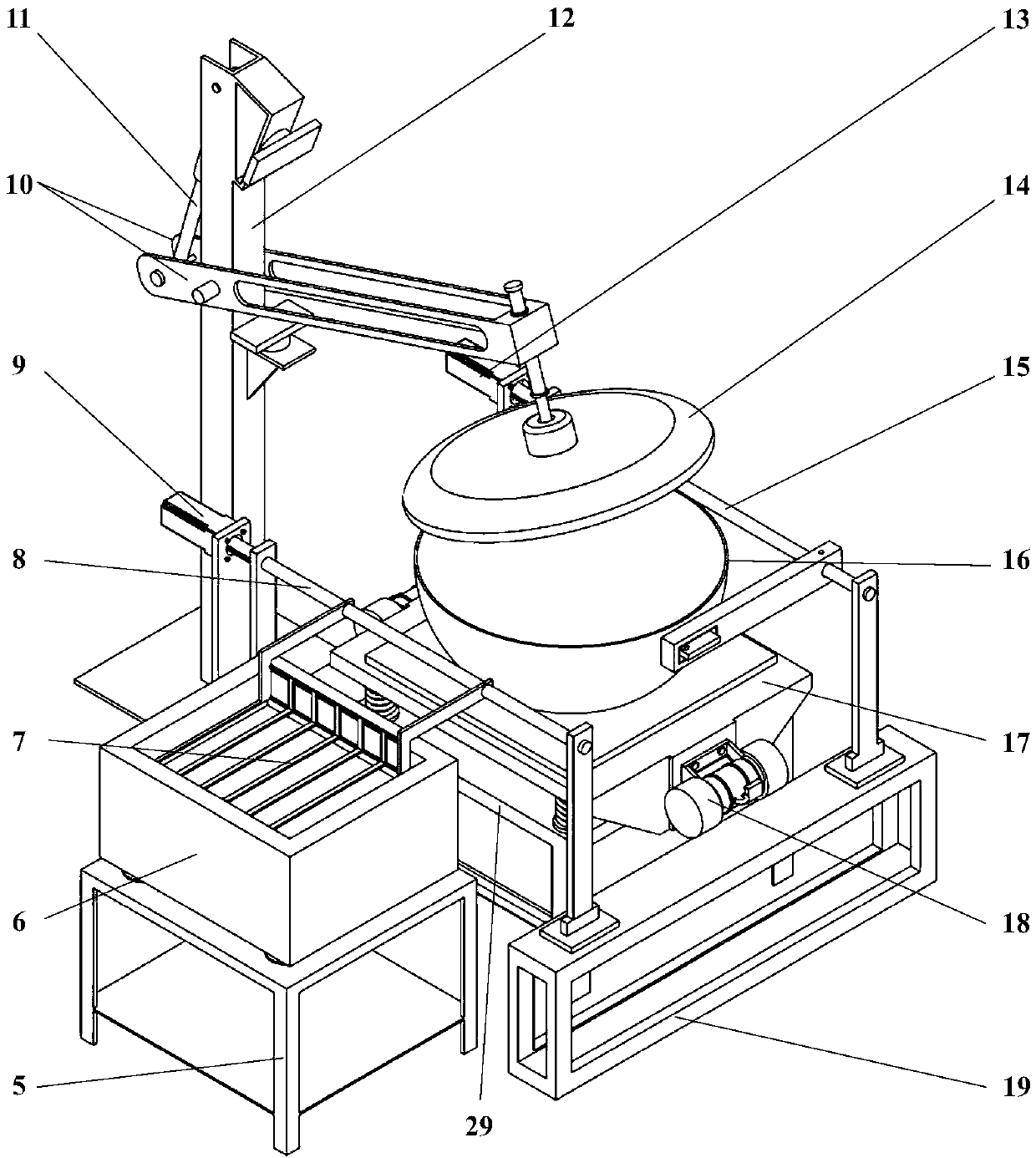

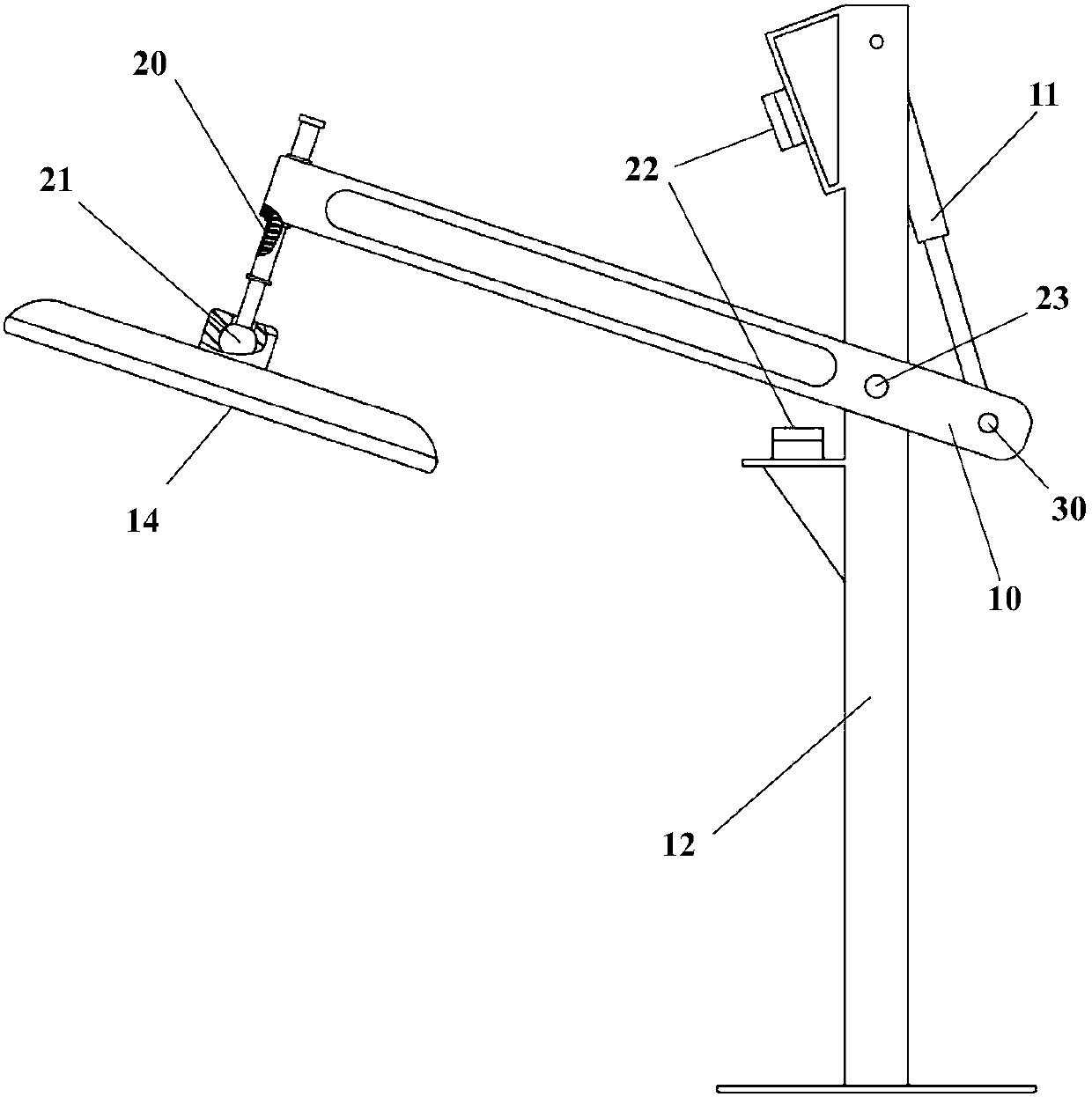

[0042] Such as figure 1 with figure 2 As shown, in the present embodiment, the heating device 2 is to support a temperature-adjustable tin furnace 6 on the tin furnace frame 5, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com