Prediction method of nugget diameter in resistance spot welding

A nugget diameter and resistance spot welding technology, applied in resistance welding equipment, welding equipment, welding power sources, etc., can solve problems such as poor practicability, reduce force imbalance, quickly predict nugget diameter online, and reduce real-time calculation. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1. Prediction of nugget diameter in spot welding of 30CrMnSi structural steel.

[0020] 1. Use NA-200-4 single-phase AC spot welding machine.

[0021] 2. The 30CrMnSi structural steel specimen (100mm×20mm×1.2mm; 100mm×20mm×1.5mm) was polished with gauze paper for surface cleaning.

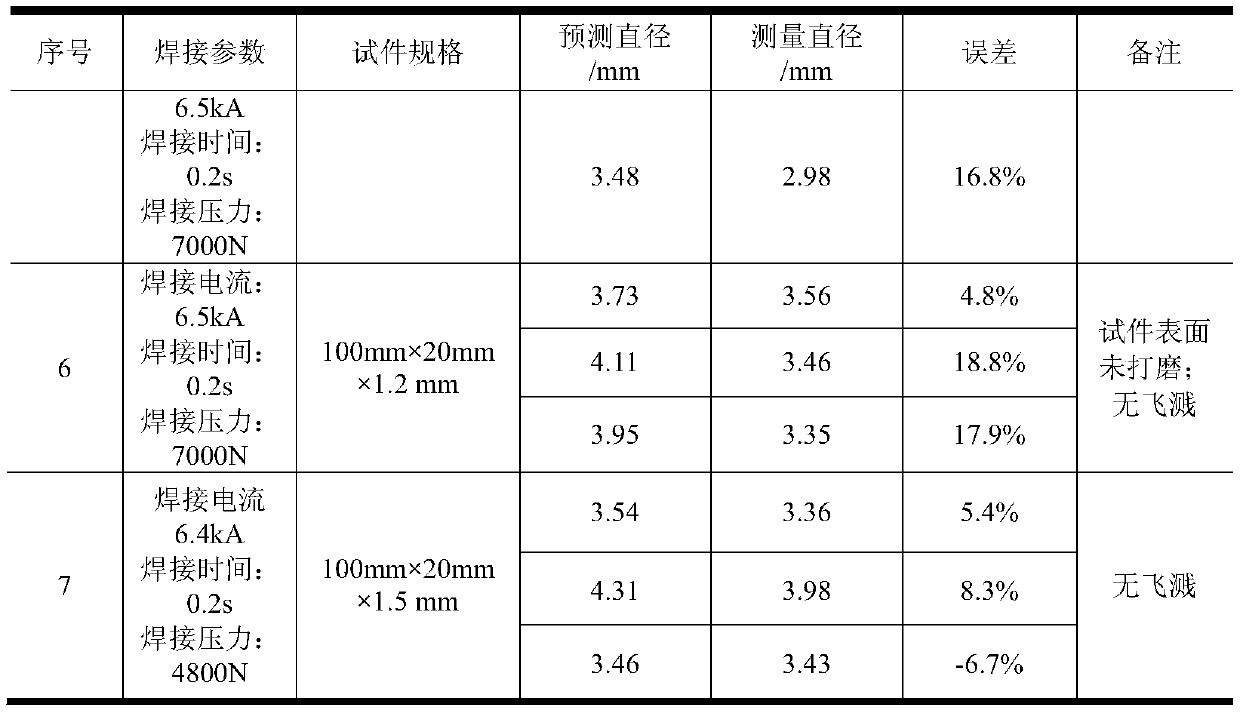

[0022] 3. Carry out three-point continuous lap spot welding of two-layer boards according to the parameters in Table 1, and the spot welding distance is 35mm. Collect welding current and electrode pressure signals during welding.

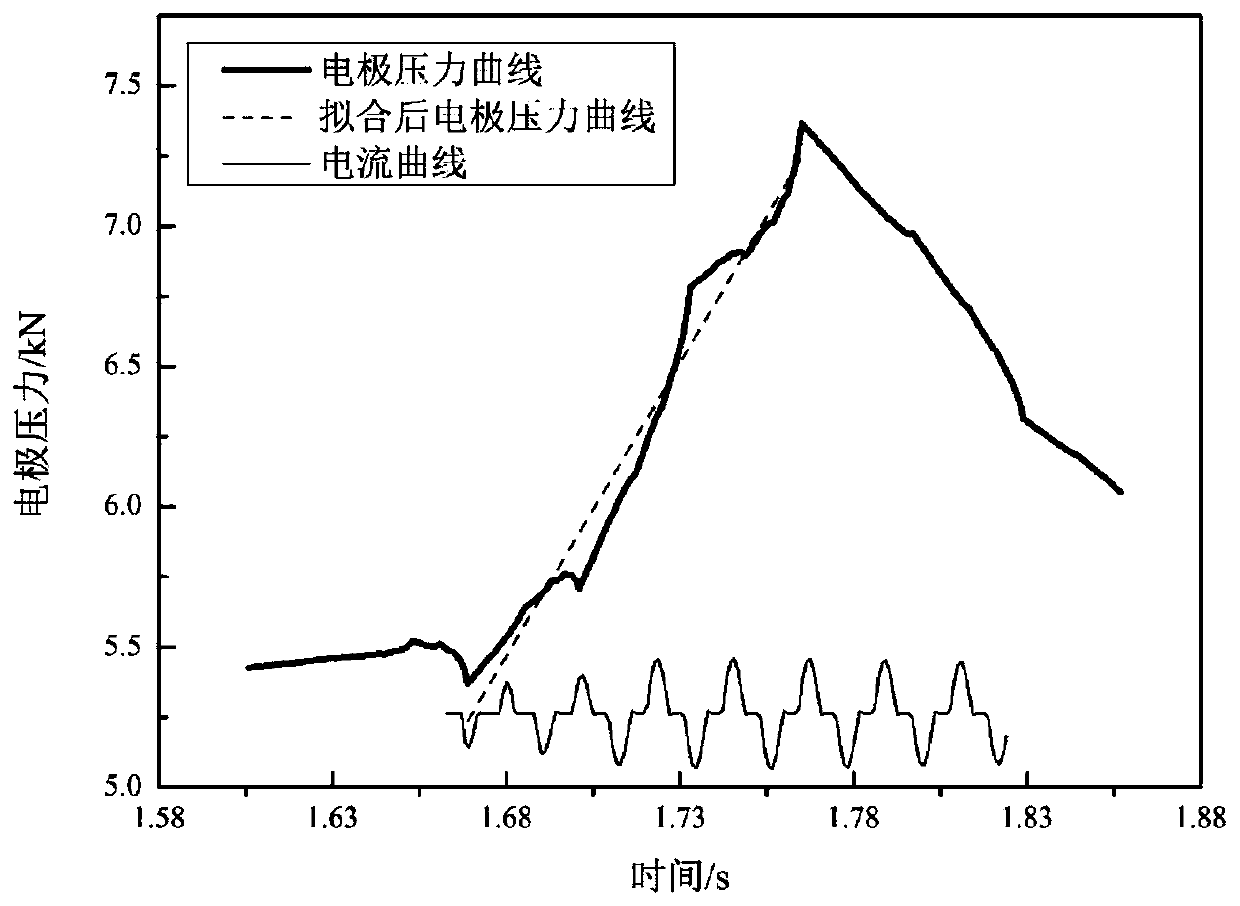

[0023] 4. Select the point on the electrode pressure curve corresponding to the start of the welding process as the starting point, and the peak pressure as the ending point, and calculate the slope S of the pressure curve between the starting point and the ending point after a one-dimensional linear fitting.

[0024] 5. Substitute the obtained slope S into D=0.149S+2.732 to obtain the predicted value D of the nugget diameter.

[0025] 6. The diameter o...

Embodiment 2

[0029] Example 2. 1Cr18Ni9Ti stainless steel spot welding nugget diameter prediction.

[0030] 1. Use NA-200-4 single-phase AC spot welding machine.

[0031] 2. Use cotton yarn to remove surface oil stains on the 1Cr18Ni9Ti stainless steel specimen (100mm×20mm×1.0mm).

[0032] 3. Carry out three-point continuous lap spot welding of two-layer boards according to the parameters in Table 2, and the spot welding distance is 35mm. Collect welding current and electrode pressure signals during welding.

[0033] 4. Select the point on the electrode pressure curve corresponding to the start of the welding process as the starting point, and the peak pressure as the ending point, and calculate the slope S of the pressure curve between the starting point and the ending point after a one-dimensional linear fitting.

[0034] 5. Substitute the obtained slope S into D=0.149S+2.732 to obtain the predicted value D of the nugget diameter.

[0035] 6. The diameter of the nugget is measured thr...

Embodiment 3

[0039] Example 3. Q235 low carbon steel spot welding nugget diameter prediction.

[0040] 1. Use NA-200-4 single-phase AC spot welding machine.

[0041] 2. Grind the Q235 low carbon steel specimen (100mm×20mm×1.0mm) with gauze paper for surface cleaning.

[0042] 3. Carry out three-point continuous lap spot welding of two-layer plates according to the parameters in Table 3, and the spot welding distance is 35mm. Collect welding current and electrode pressure signals during welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com