Car body flexible positioning fixture mechanism used for aluminum alloy head cover laser welding of lightweight car body

A flexible positioning and laser welding technology, used in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of increased plate clearance, difficulty in ensuring the Y-direction accuracy of the vehicle side wall, and welding seam offset, etc. Wide range, high practical value, and small installation footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following describes in detail the specific implementation of the flexible positioning fixture mechanism of the light-weight aluminum alloy roof cover laser welding body of the present invention with reference to the accompanying drawings.

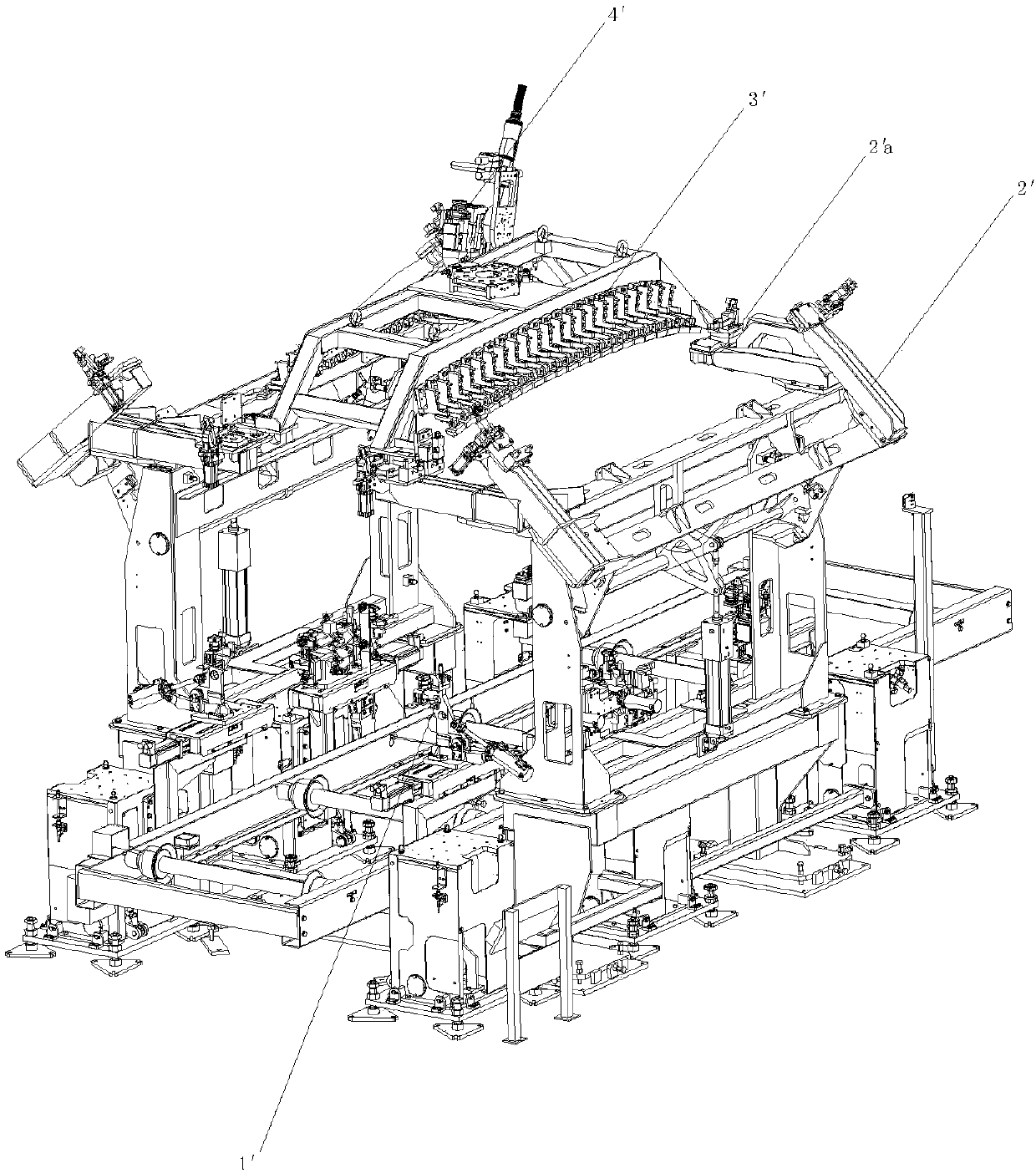

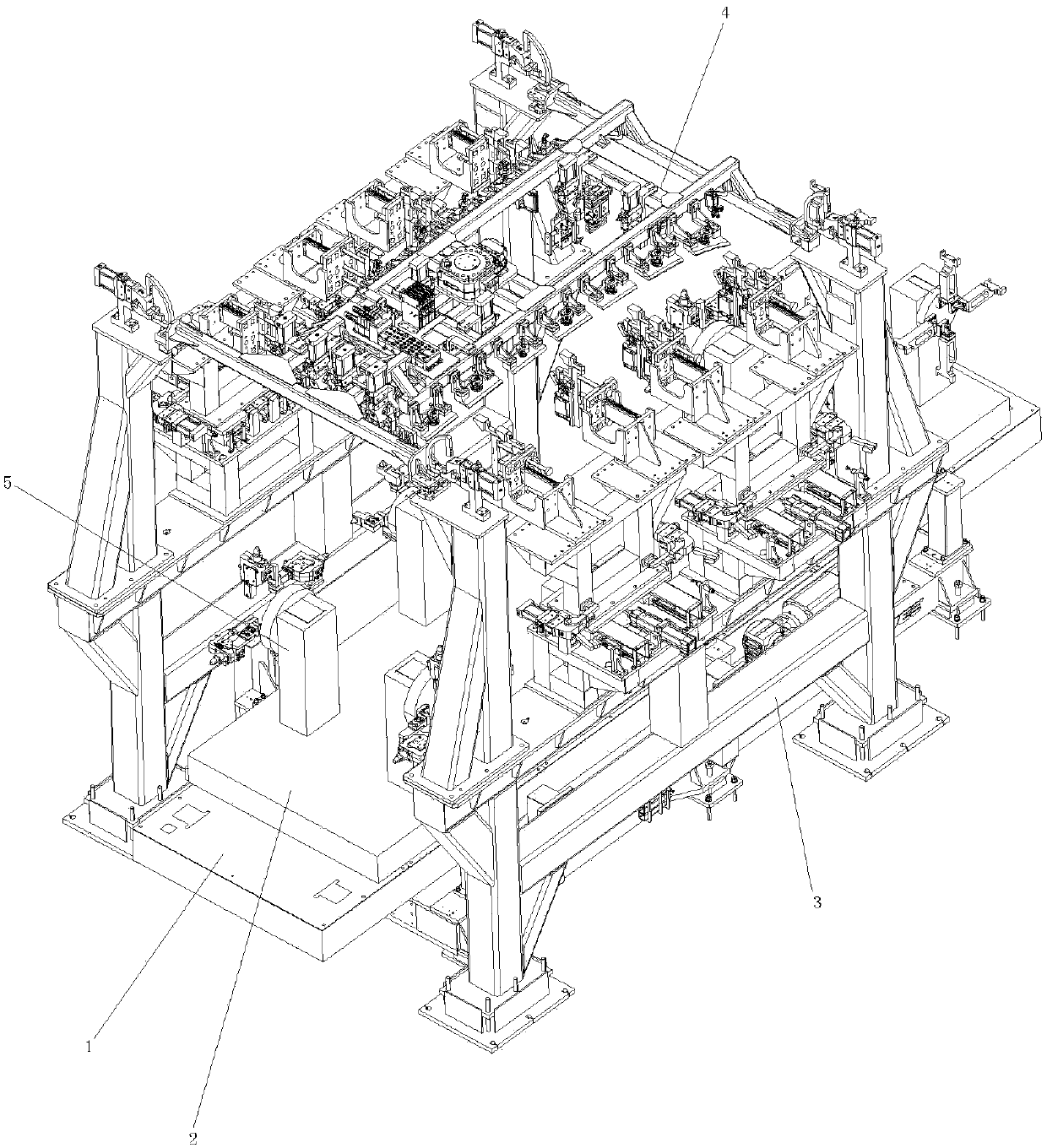

[0034] Please refer to figure 2 , the flexible positioning fixture mechanism of the lightweight aluminum alloy roof cover laser welding body of the present embodiment has the following structure:

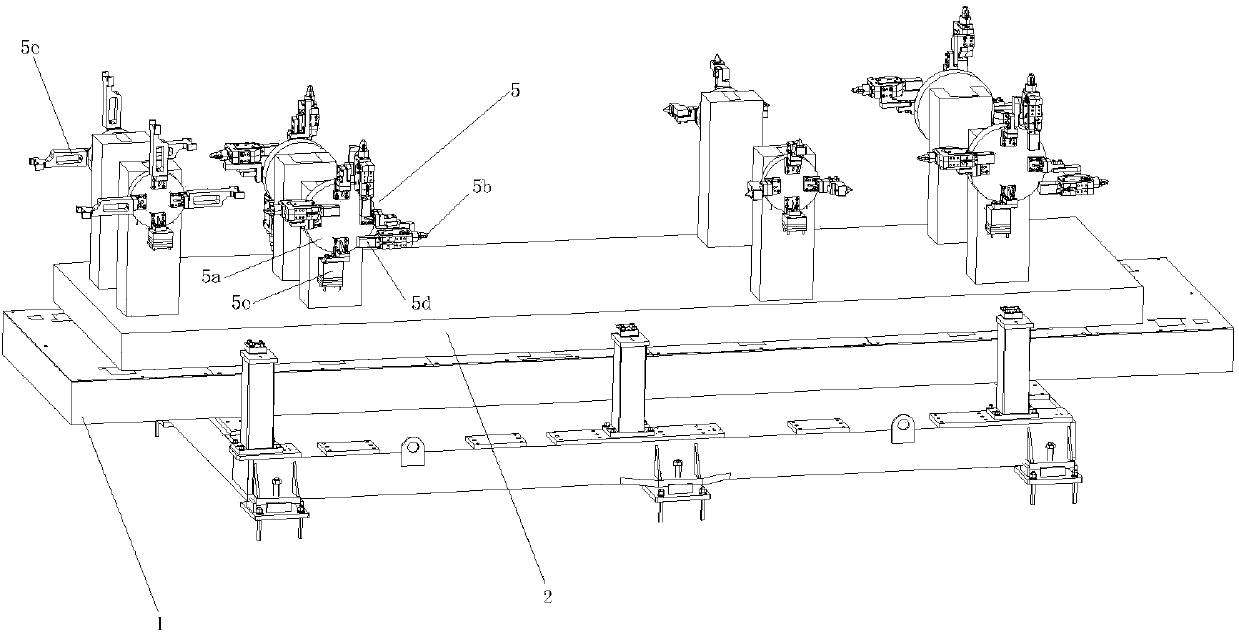

[0035] Such as image 3 As shown, a flexible trolley 1 is set, and the flexible trolley 1 is transported to the laser welding station by means of the high-speed roller bed 2 below it, and multiple groups of windmill disk flexible switching devices 5 are arranged symmetrically on the left and right sides of the upper end of the flexible trolley 1, in different positions A plurality of positioning pins 5b or a plurality of support blocks 5c adapted to the bottom end structure of each vehicle body are set on the switching flange 5a of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com