Fixture for combined spot welding of relay armatures

A combination point and relay technology, used in manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of restricting the qualified product rate of products, high labor intensity, low welding efficiency, etc., and achieve good consistency, high work efficiency, Easy clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

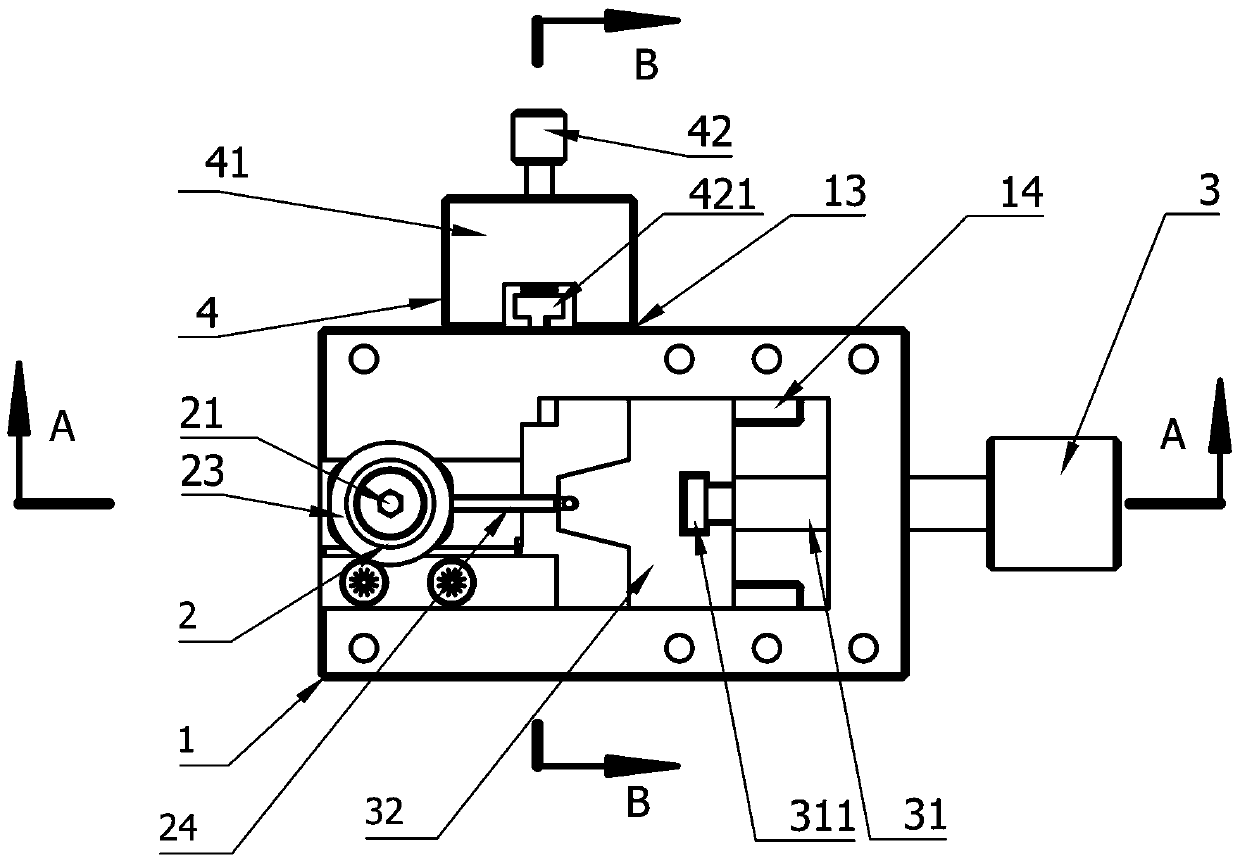

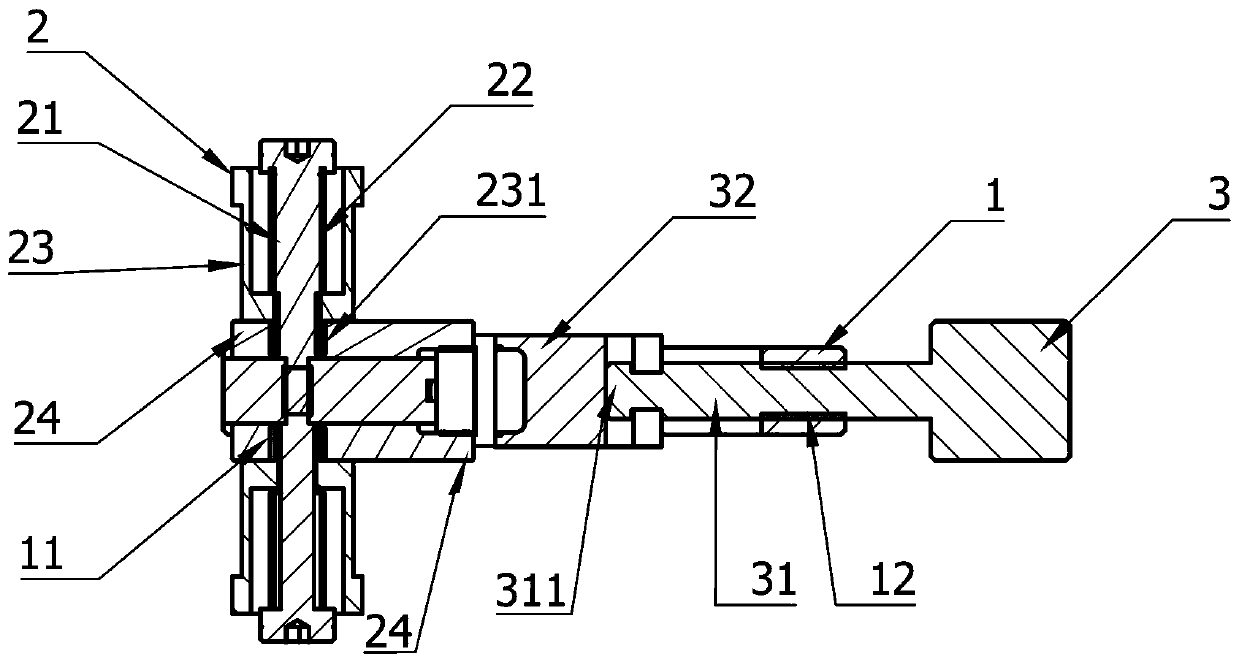

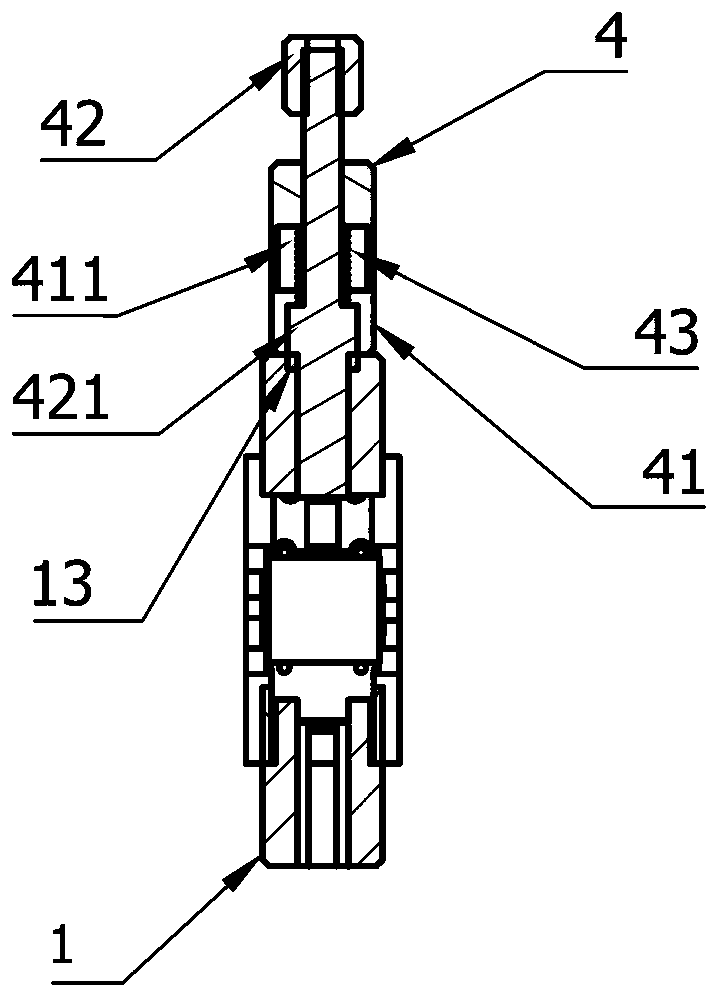

[0027] The invention is applicable to the positioning fixture for relay armature combination spot welding. The invention distributes two shaft fixing pieces of the relay armature combination shaft symmetrically on the two surfaces of the relay armature, and is clamped and positioned by the invention.

[0028] Concrete clamping process of the present invention is as follows:

[0029] Refer to figure, figure 2 , image 3 Place the relay armature together with the shaft fixing piece in the cavity of the clamp body 1, and make the two sides of the shaft fixing piece face the upper and lower pressing mechanism 2, and push the relay armature and the shaft fixing piece into the two pressing blocks of the upper and lower pressing mechanism 2 24, the shaft fixing piece touches the two pressing blocks 24 of the upper and lower pressing mechanism 2, and the pressing block 24 together with the pressing block sleeve 23 overcomes the elastic force of the first spring 22 to open; at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com